Rheological evaluation method of inferior superheavy oil flow improver

A technology of flow improver and evaluation method, which is applied in the direction of flow characteristics, scientific instruments, measuring devices, etc., can solve the problems of heavy auxiliary workload, heavy testing workload, and large volatility, and achieve simple, high-efficiency, cost-effective, and strong application value , the effect of strong correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

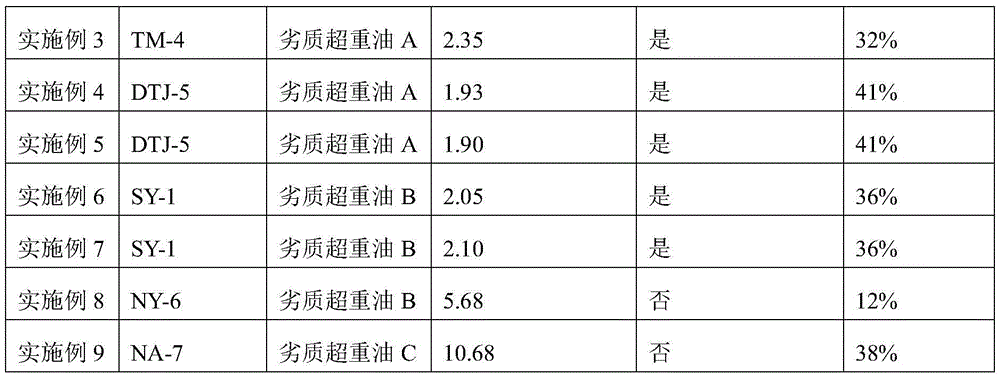

Embodiment 1

[0026] Place the commercially available flow improver sample SY-1 on the fixture of a strain-controlled rheometer. The torque accuracy of the rheometer is 0.1nNm, the torque range is 0.01μNm-200mNm, and the normal stress range is 0.01-50N. The applied detection frequency range is 1×10 -5 -628rad / s, set the temperature to 200°C, equilibrate to 2min, apply 1% strain, set the detection frequency range to 0.001-100rad / s, take 3 data points for each order of magnitude in logarithmic mode, and set the integration time to 1 cycle, read the phase angle data in the full test frequency range, and read its minimum value, which is listed in Table 1.

[0027] At the same time, 100ppm of the flow improver sample SY-1 was added to the inferior super heavy oil A, and the ratio of its fluidity improvement was determined by the traditional loop test, which is listed in Table 1.

Embodiment 2

[0029] Put the synthetic flow improver sample BR-3 on the fixture of the strain-controlled rheometer, the torque accuracy of the rheometer is 0.1nNm, the torque range is 0.01μNm-200mNm, and the normal stress range is 0.01-50N, which can be applied The detection frequency range is 1×10 -5 -628rad / s, set the temperature to 250°C, equilibrate to 5min, apply 5% strain, set the detection frequency range to 0.0001-500rad / s, take 5 data points for each order of magnitude in logarithmic mode, and set the integration time to 2 cycles, read the phase angle data in the full test frequency range, and read its minimum value, which is listed in Table 1.

[0030] At the same time, 100ppm of the flow improver sample BR-3 was added to the inferior super heavy oil A, and the ratio of its fluidity improvement was determined by the traditional loop test, which is listed in Table 1.

Embodiment 3

[0032] Place the commercially available flow improver sample TM-4 on the fixture of a strain-controlled rheometer, which has a torque accuracy of 0.1nNm, a torque range of 0.01μNm-200mNm, and a normal stress range of 0.01-50N, which can be applied The detection frequency range is 1×10 -5 -628rad / s, set the temperature to 300°C, equilibrate to 3min, apply 3% strain, set the detection frequency range to 0.01-500rad / s, take 7 data points for each order of magnitude in logarithmic mode, and set the integration time to For 3 cycles, read the phase angle data in the full test frequency range, and read its minimum value, which is listed in Table 1.

[0033] At the same time, 100ppm of the flow improver sample TM-4 was added to the inferior super-heavy oil A, and the ratio of its fluidity improvement was determined by the traditional loop test, which is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com