DF10D series locomotive non-auxiliary generating fault processing method

A fault handling method and unassisted technology, applied in printed circuit testing, electronic circuit testing and other directions, can solve problems such as affecting driving safety, inability to operate electronically controlled valves, etc., to reduce the company's production losses and shorten fault repair time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

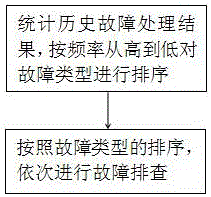

[0026] A method for troubleshooting a locomotive without auxiliary power generation, comprising the following steps:

[0027] Step 1: Count historical fault handling results, and sort fault types according to frequency from high to low;

[0028] Step 2: According to the sorting of fault types in step 1, troubleshoot in sequence.

[0029] Carrying out comprehensive, in-depth and detailed research and analysis on the auxiliary power generation circuit unit, and making statistics on the fault treatment results for many years, the inventor found that the following fault points cause the proportion of locomotives without auxiliary power generation to account for more than 90%. According to the fault point frequency from high to low, they are:

[0030] 1) The auxiliary contact QC1 of the starting contactor is faulty;

[0031] 2) Fix the failure of the auxiliary contact GFC of the power generation contactor;

[0032] 3) Diesel locomotive controller DLC failure;

[0033] 4) The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com