Method for laying optical cable inside fire protection vent pipe

A ventilation pipe and fire-fighting technology, which is applied in the direction of optical fiber/cable installation, etc., can solve the problems of difficult laying of optical cables, large friction between optical cables and air pipes, etc., and achieves the effect of simple method, increased laying speed, and improved lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

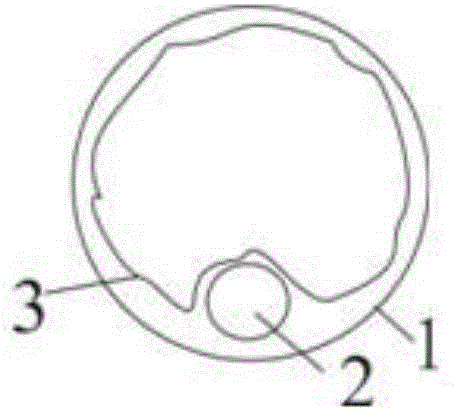

[0015] Such as figure 1 As shown, the structure of the cross-section of the fire-fighting ventilation pipe 1 when the optical cable 2 is laid. First, water and washing powder are prepared according to the ratio of 30:1 to prepare lubricating liquid 3, and a little soap liquid or detergent such as washing powder is added to tap water to prepare soap liquid. Lubricating liquid 3 can improve the lubricity of the inner wall of the trachea; Before 2, pour a little soap liquid into the trachea through the funnel container to increase the lubricity of the inner wall of the trachea and reduce friction.

[0016] In order to improve the effect of this method, 3MPa~5MPa compressed air can be used to purge the air pipe. On the one hand, the roundness of the air pipe can be improved, so that the lubricating liquid 3 can be evenly distributed on the inner wall of the air pipe. Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com