A touch substrate, its manufacturing method, and a touch display device

A substrate and touch technology, applied in instruments, calculations, electrical digital data processing, etc., can solve the problem of uneven capacitance distribution in the touch area, improve touch accuracy and user experience, improve the uneven distribution of edge capacitance, The effect of uniform capacitance distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

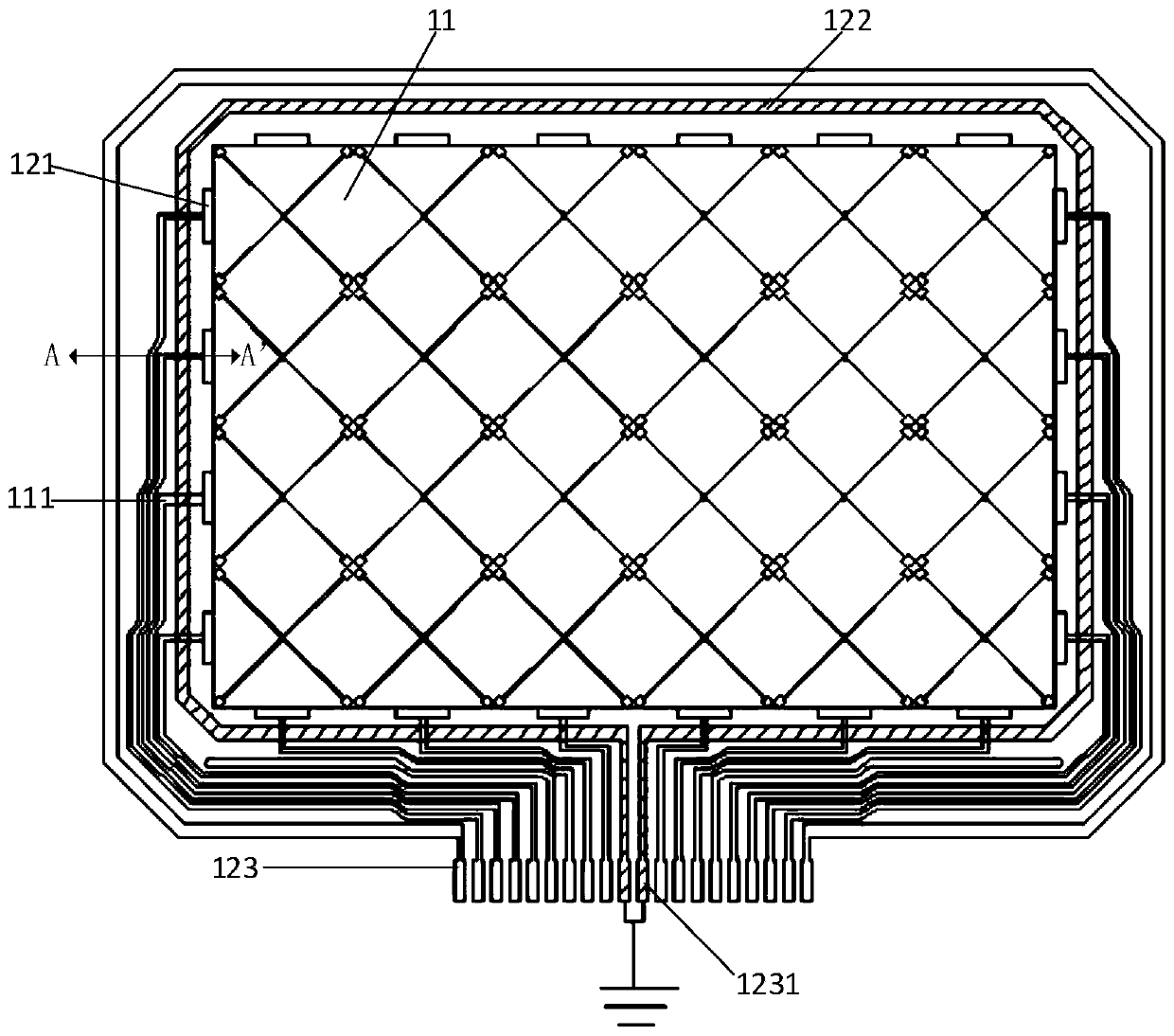

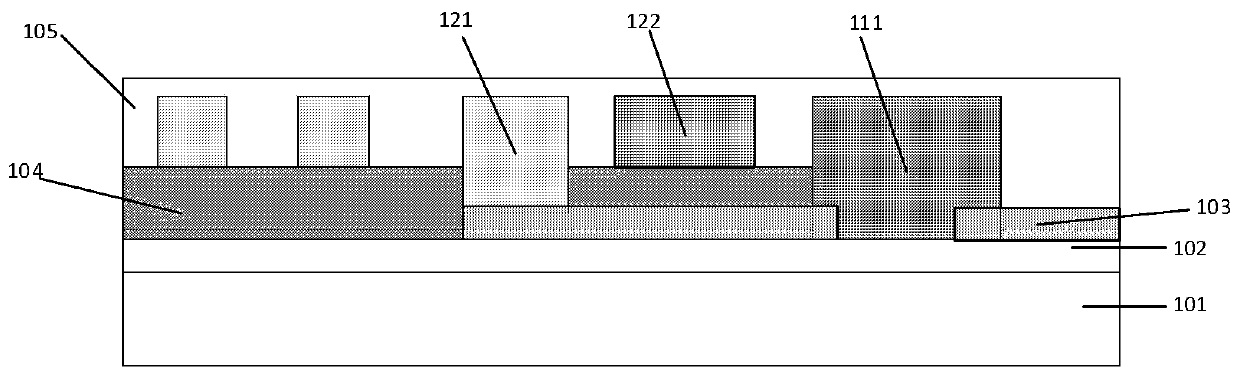

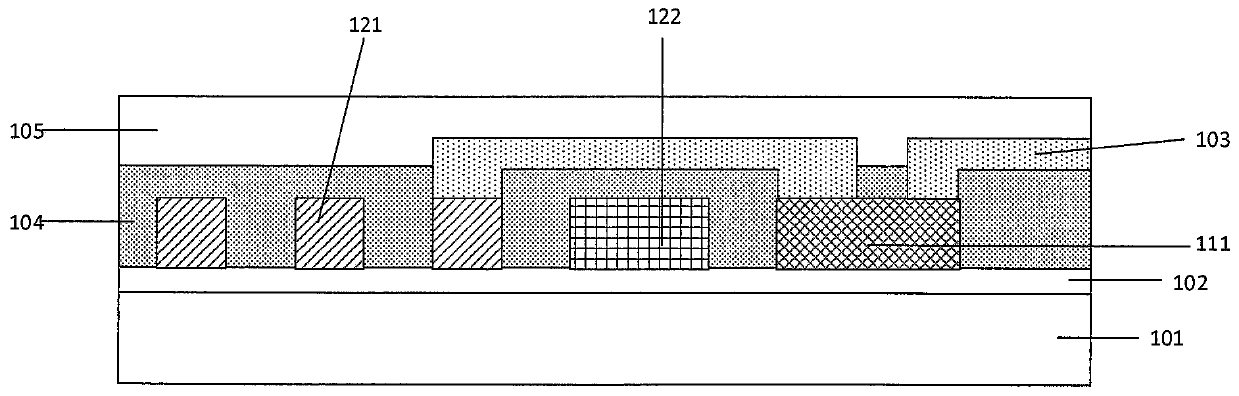

[0072] exist figure 1 , figure 2 and image 3 A first embodiment of the invention is shown.

[0073] figure 1 is a schematic plan view of the touch substrate according to the first embodiment of the present invention, figure 2 is the substrate edge according to the first embodiment of the present invention figure 1 The schematic diagram of the cross-section in the direction of A-A', image 3 is another substrate edge according to the first embodiment of the present invention figure 1 The schematic diagram of the cross-section in the direction of A-A' is now combined with figure 1 , figure 2 and image 3 A first embodiment of the present invention will be described.

[0074] Such as figure 1 and figure 2 As shown, a specific embodiment of the present invention provides a touch substrate, including a substrate 1 . The substrate 1 is provided with a touch area 11 and a peripheral area 12 around the display area. The peripheral area 12 includes at least one signal...

no. 2 example

[0088] Such as Figure 4 and Figure 5 Shown is the second embodiment of the present invention.

[0089] Figure 4 is a schematic plan view of the touch substrate according to the second embodiment of the present invention, Figure 5 It is a partial enlarged perspective view of the touch substrate in the second embodiment of the present invention where the signal trace 121 and the metal bonding block 111 overlap.

[0090] Such as Figure 4 and Figure 5 As shown, a specific embodiment of the present invention provides a touch substrate, including a substrate 1 . The substrate 1 is provided with a touch area 11 and a peripheral area 12 around the display area. The peripheral area 12 includes at least one signal trace 121 and a shielding wire 122 . The touch control substrate further includes a peripheral grounding device or grounding line 13 located on the periphery of the signal line 121 . A peripheral grounding device or grounding wire 13 is electrically connected to ...

no. 3 example

[0104] Such as Figure 6 or Figure 7 As shown, the embodiment of the present invention provides a manufacturing method of a touch substrate, the manufacturing method comprising:

[0105] Such as Figure 6 As shown, a touch area and a peripheral area are set on the touch substrate. Make a black matrix on the substrate, the structure of the black matrix is as follows figure 2 The middle black matrix 102 is used to form a light-shielding area.

[0106] An ITO layer is formed on the black matrix, and an ITO pattern is formed through a patterning process. The ITO pattern includes an ITO bridge for connecting signal lines and metal bonding blocks. The ITO bridge structure is as follows Figure 5 Middle ITO Bridge 1031.

[0107] A first insulating layer is formed on the ITO layer, and the first insulating layer has a structure such as figure 2 The middle first insulating layer 104 . Make a via hole on the first insulating layer, the via hole structure is as Figure 5 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com