Turbine-generator rotor adopting sub-slot air supplying and transverse wind gap cooling mode

A steam turbine generator and transverse wind technology, applied in wind power generation, electrical components, electromechanical devices, etc., can solve the problems of complicated fan design and installation, and achieve better cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following non-limiting examples illustrate the invention.

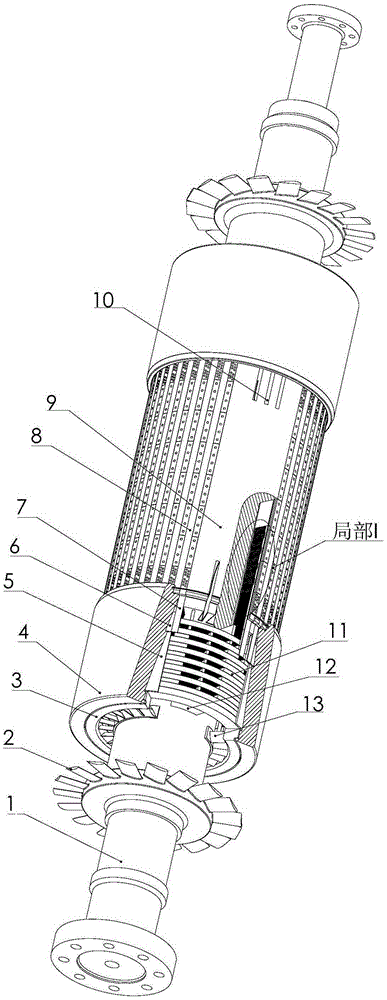

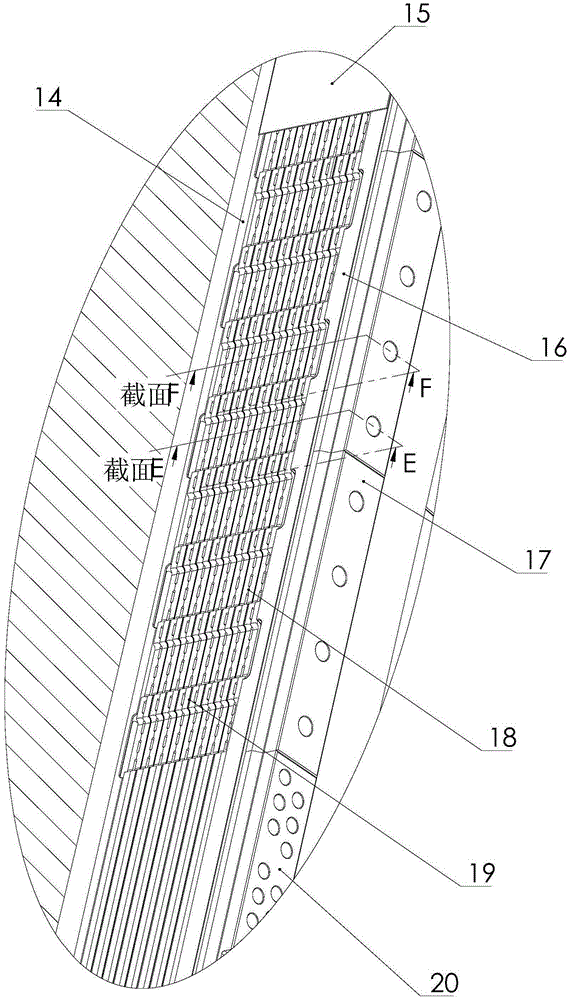

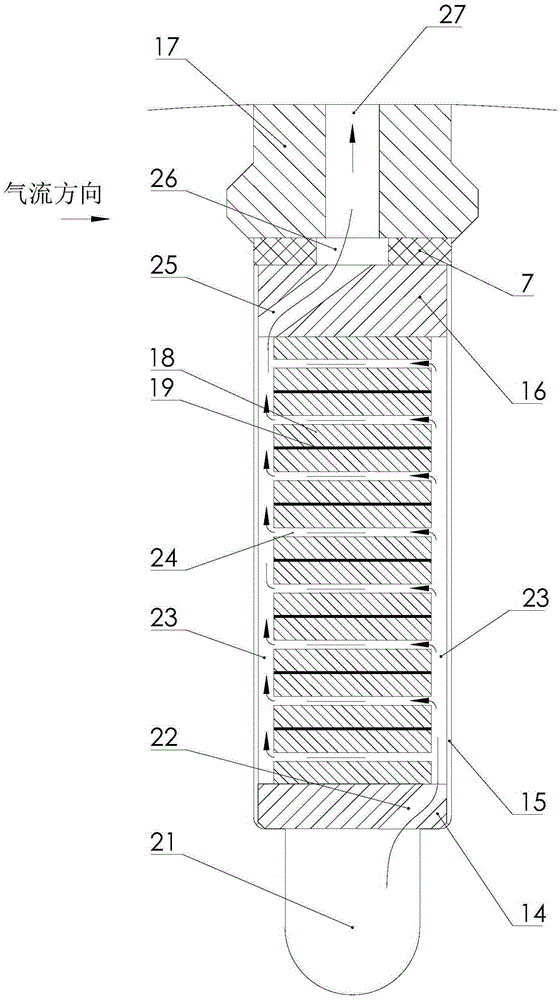

[0049] see Figure 1 to Figure 6 , the rotor of the present invention that adopts auxiliary slots for air supply and lateral air gap cooling, the rotor slot wedges 17 are flush with the rotor surface, the slot wedges 17 have no wind buckets (wind buckets, wind buckets), and the rotor teeth 9 / 10 have no wind buckets on the surface Horizontal ventilation slots. The fan 2 is installed at both ends of the rotating shaft 1, the rotor slot is embedded with a coil 18 (rotor copper wire turn), the slot wedge 17 and the rotor slot are in turn damping strips 7 and insulating pads 16 under the wedge, the bottom of the slot is milled Slot 21, between the wire slot and the auxiliary slot 21 is the slot bottom insulating pad 14, the end of the large tooth 9 is milled and thrown off the air slot 10; the slot bottom insulating pad 14, and the insulating pad 16 under the wedge, and the damping strip 7 in the slot and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com