Filter method applied bale to power plant heat exchange and purification

A method of filtration, technology for power plants, applied in the field of power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This implementation mode provides an example to further illustrate the present invention.

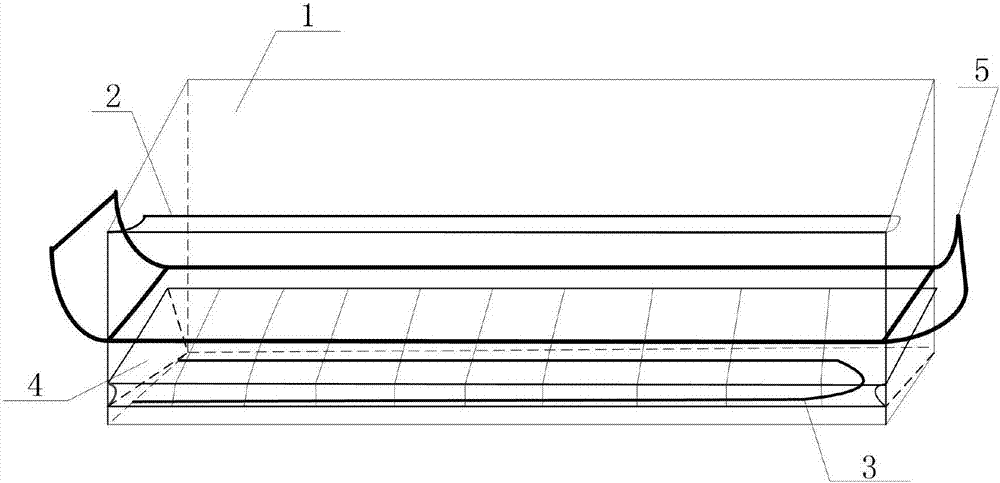

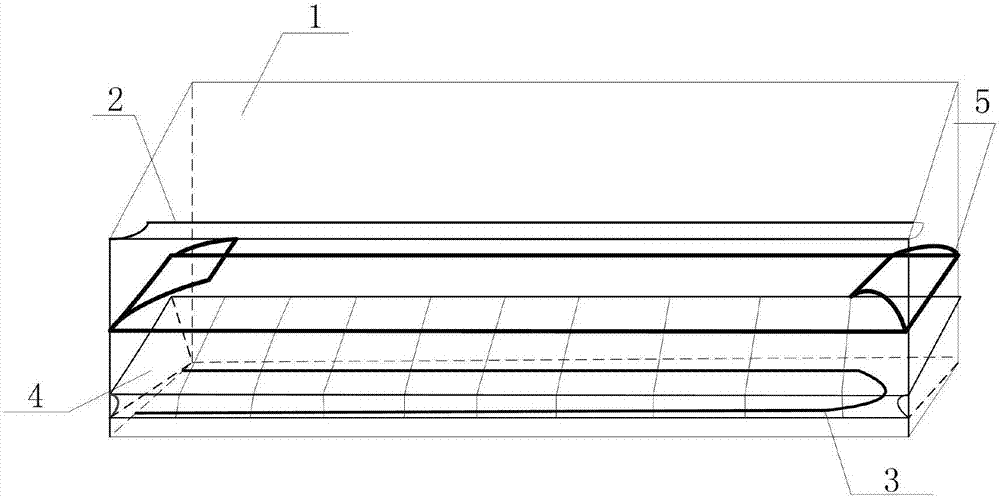

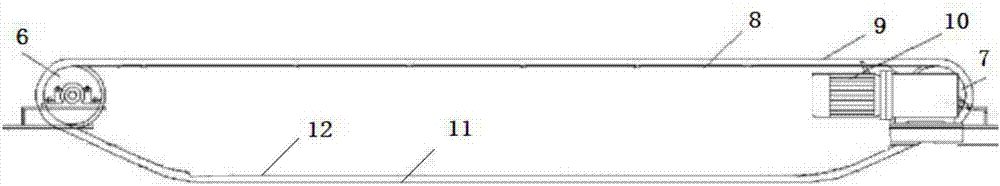

[0018] In one embodiment, the filter system suitable for heat exchange and purification in power plants includes a closed ditch, which has an inclined flat-shaped upper cover 1, and an insulating layer is laid on the outer surface of the upper cover 1, along which the upper cover 1, a number of condensed water drainage channels are opened on it, and the drainage channels converge in the water guide groove 2 placed on the inclined bottom edge of the upper cover 1, and hermetic doors are installed at both ends of the airtight ditch. , the water guide groove 2 stretches out from the airtight door. During the heat exchange process, a large amount of water vapor will condense into condensed water on the upper cover 1, which is generally considered as a kind of recyclable clean water. In order to recycle this part of water, the upper cover 1 is set as a flat-shaped inclined upper Cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com