High-low-temperature mechanical performance testing device for stretching mechanism

A technology of stretching mechanism and testing device, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., and can solve problems such as the inability to achieve active follow-up and the need to improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

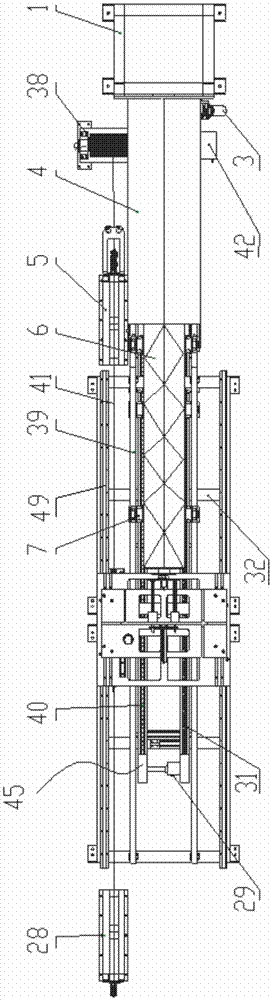

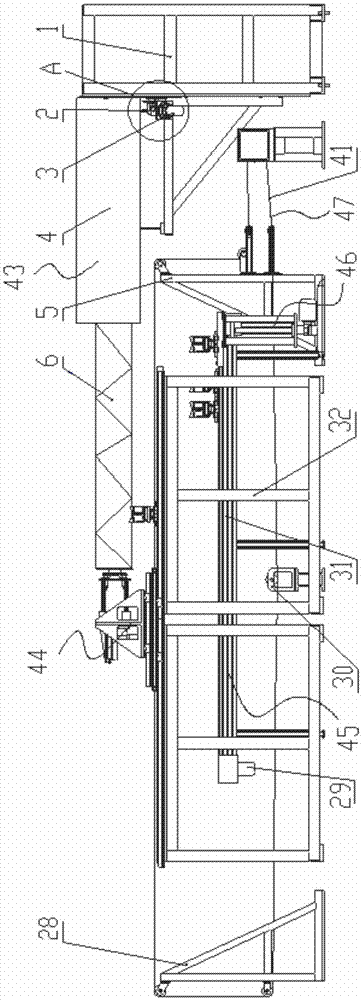

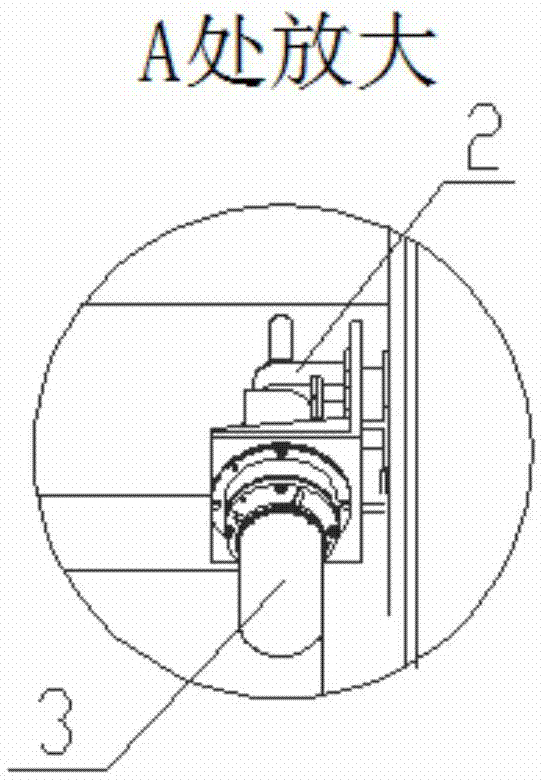

[0029] Such as Figure 1~2 As shown, the present invention includes a truss storage unit 43, a force loading unit 44, a force loading follower unit 47, a force loading transmission frame body 32 and a gravity balance trolley 7, wherein the force loading unit 44 is movably installed on the force loading transmission On the truss body 32, the force loading unit 44 is driven and moved by the force loading follow-up unit 47, and the truss 6 to be tested is arranged in the truss storage unit 43. When the truss 6 is unfolded for testing, the truss 6 The free end is connected with the force loading unit 44, and the part of the truss 6 protruding from the truss storage unit 43 is lifted and supported by the gravity balance trolley 7, and the force loading unit 44 and the gravity balance trolley 7 follow the truss 6 Unfold movement, the pressure sensor 9 for measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com