Blowing guide device and battery cell winding system

A guiding device and guiding technology, applied in the direction of primary batteries, battery assembly machines, and equipment for manufacturing primary batteries, can solve the problem of unqualified alignment of pole pieces and separators, affecting the quality of batteries, affecting the yield and safety performance of batteries and other problems, to achieve the effect of preventing sagging, preventing the pole piece from sagging, and balancing gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

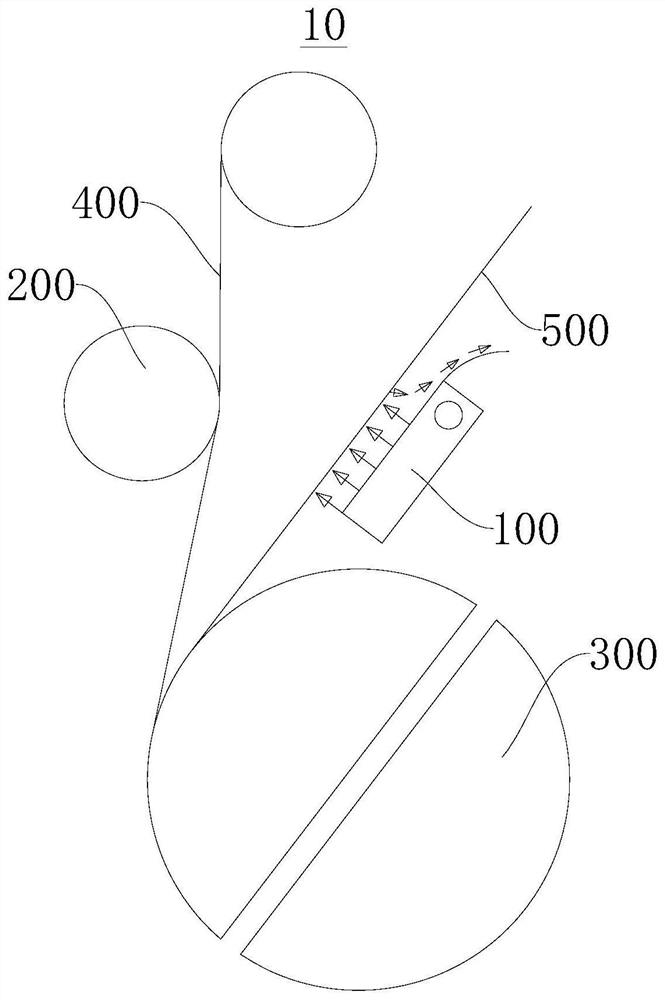

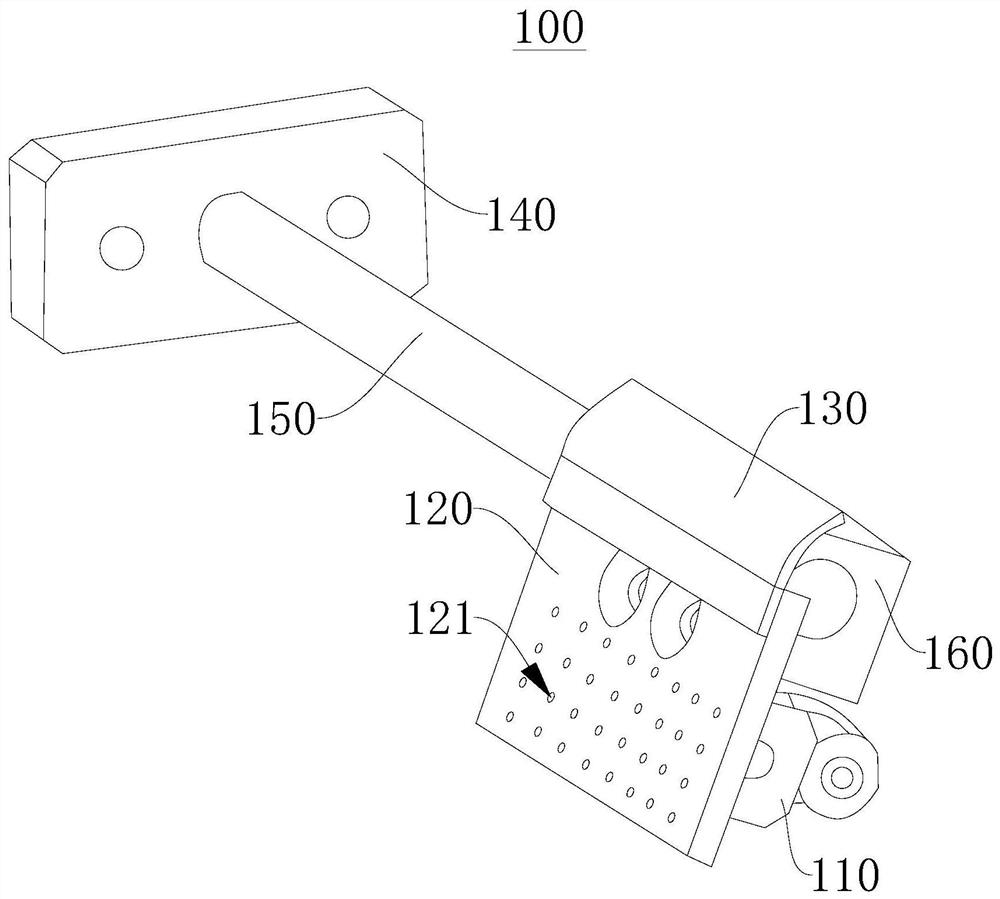

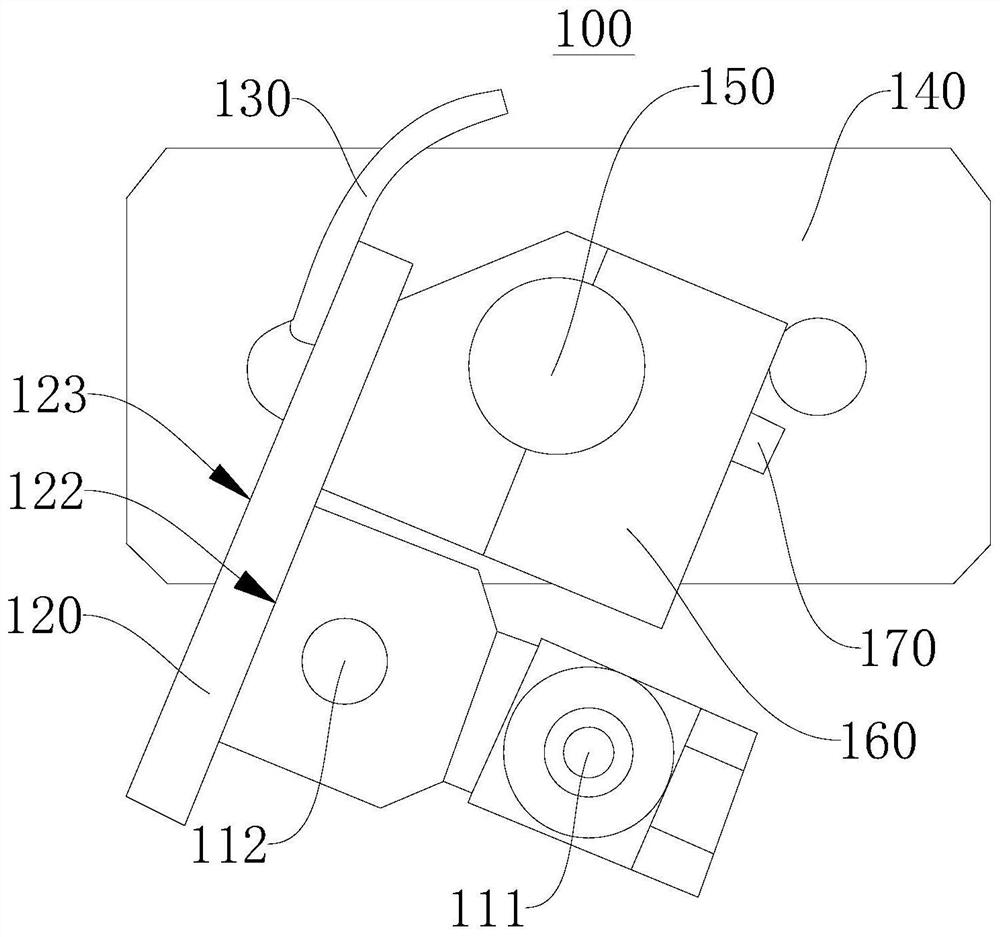

[0034] Please refer to figure 1 (Hollow arrows in the figure indicate the direction of air flow), an embodiment of the present invention provides a cell winding system 10 for winding and producing cells. It can blow and guide the pole piece 500 to balance the gravity of the pole piece 500 and prevent the pole piece 500 from sagging, and the guided airflow can flow out smoothly without affecting the winding of the pole piece 500, which is practical and reliable.

[0035] It should be noted that the cell winding system 10 includes a diaphragm roller 200 , an air blowing guide device 100 and a winding needle 300 . The diaphragm roller 200 is used to limit the diaphragm 400, and sends the diaphragm 400 into the winding needle 300, and the blowing guide device 100 is used to blow and guide the pole piece 500 so that the pole piece 500 enters the winding needle 300, and the winding needle 300 is used to drive the diaphragm 400 and the pole piece 500 to rotate at the same time, so a...

no. 2 example

[0048] Please refer to Figure 5 The embodiment of the present invention provides an air blowing guide device 100. Compared with the first embodiment, the difference of this embodiment is that the adjustment mode of the air blowing guide device 100 is electric drive.

[0049] In this embodiment, the air blowing guide device 100 further includes a first driving mechanism 180 and a second driving mechanism 190 . The first driving mechanism 180 is installed on the fixing plate 140 and is connected with the connecting shaft 150. The first driving mechanism 180 is used to drive the mounting table 160 away from or close to the fixing plate 140 through the connecting shaft 150, thereby driving the substrate 120 away from or approaching the fixing plate. 140 , that is to realize the function of translation of the substrate 120 along the axial direction of the connecting shaft 150 . The second driving mechanism 190 is installed on the connecting shaft 150 and connected to the mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com