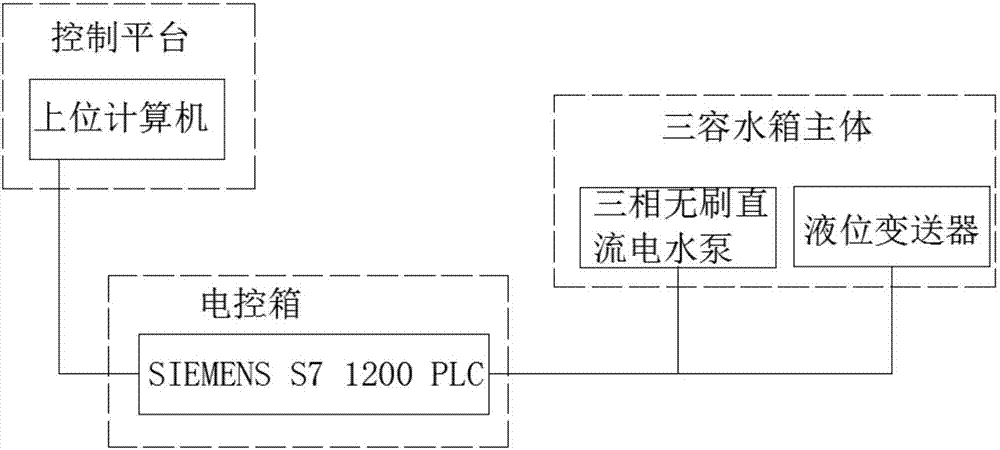

Model-free adaptive-control water tank liquid level control system

A model-free self-adaptive, liquid level control technology, applied in liquid level control, control/regulation system, non-electric variable control, etc., can solve the problem of three-capacity water tank system staying in the simulation research stage, etc., to achieve the realization of water flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

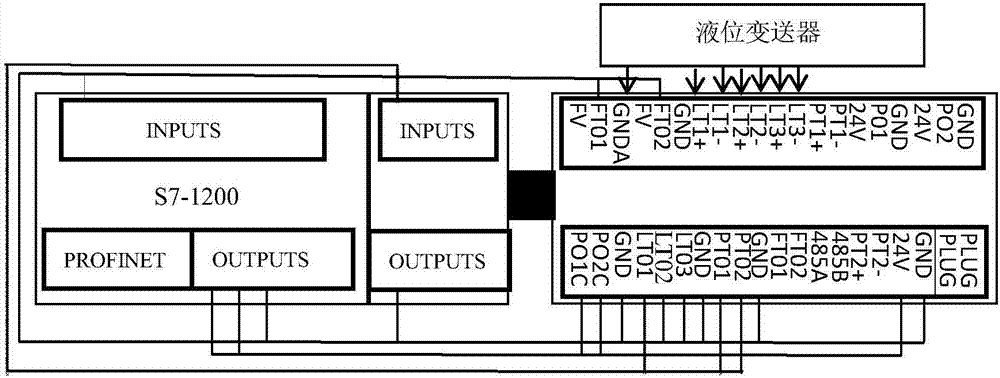

Method used

Image

Examples

Embodiment example 1

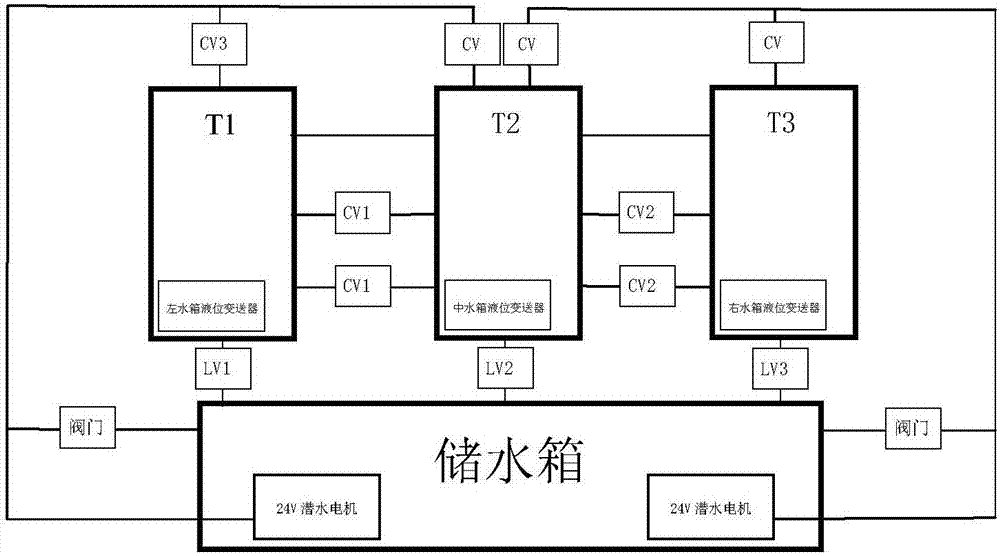

[0064] Implementation case 1: The control algorithm steps of the main body of the three-capacity water tank are:

[0065] (1) Tank (T1), Tank (T2), and Tank (T3) are first set to be glass container 1, glass container 2, and glass container 3 in the main body of the three-capacity water tank respectively;

[0066] (2) Use CV1, CV2, CV3 to describe the connection valve switches between each glass container, wherein the connection valve switch CV3 is the water inlet valve;

[0067] (3) Use LV1, LV2, and LV3 to describe the drain valves of each glass container. Assuming that the cross-sectional area of the three glass containers is s, the flow rate of the drain is controlled by manually adjusting the drain valve, and a recovery tank is installed under the drain valve for supply. water pump use;

[0068] (4) use T 1 and T 3 Respectively describe the water container into which the water pumped by the water pump flows;

[0069] (5) install the liquid level sensor detection orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com