Multi-pipe material high-altitude push equipment

A multi-pipeline and material technology, applied in conveyors, grain processing, loading/unloading, etc., can solve problems such as particle size does not meet the requirements, particle size of powdery materials does not meet the requirements, and affects product production, etc., to avoid material knots Agglomeration, avoiding excessive feeding, and increasing the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

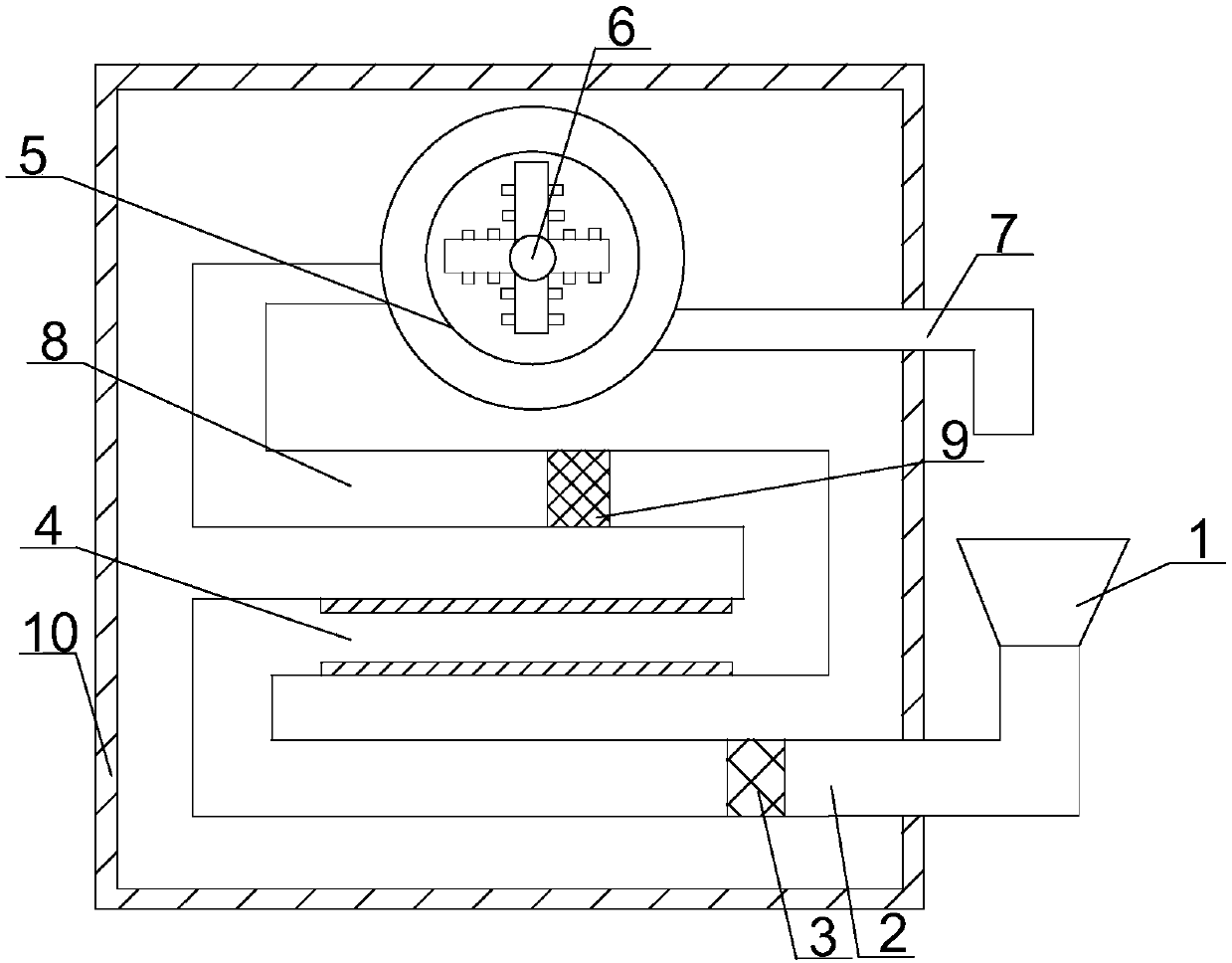

[0022] Such as figure 1 As shown, the multi-pipeline material high-altitude pushing equipment of the present invention includes a feed hopper 1, the discharge port of the feed hopper 1 is connected with a first feed pipe 2, and the facility in the first feed pipe 2 has a coarse screen 3. A second feed pipe 4 is connected above the discharge end of the feed pipe 2, a heating device is arranged inside the second feed pipe 4, and a pulverizer is connected above the discharge end of the second feed pipe 4, and the pulverizer includes Body 5, the feeding port of body 5 communicates with the discharge end of the second feed pipe 4, the inside of body 5 is provided with a rotary crushing knife 6 containing at least two blades, and the surface of the blades of said crushing knife 6 is provided with There are a plurality of protrusions, and a discharge pipe 7 is communicated with the bottom of the body 5 . There is a third feeding pipe 8 connected between the pulverizer and the second...

Embodiment 2

[0025] Based on Embodiment 1, the first feeding pipe 2, the second feeding pipe 4, the pulverizer, and the third feeding pipe 8 are all arranged inside the housing 10, and the outer surface of the housing 10 is coated with a heat insulating layer, The heat insulation layer is covered with an anti-collision layer, and the anti-collision layer is covered with an anti-corrosion layer. The feeding funnel 1 and the discharge pipe 7 are located outside the housing 10 . The shell has a protective effect on the first feeding pipe, the second feeding pipe, the pulverizer, and the third feeding pipe, so as to avoid the first feeding pipe, the second feeding pipe, the second feeding pipe, The pulverizer and the third feeding pipe were damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com