Sealing frame glue coating device

A technology for sealing sealant and coating device, which is applied to devices and coatings that apply liquid to the surface. The effect of process capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

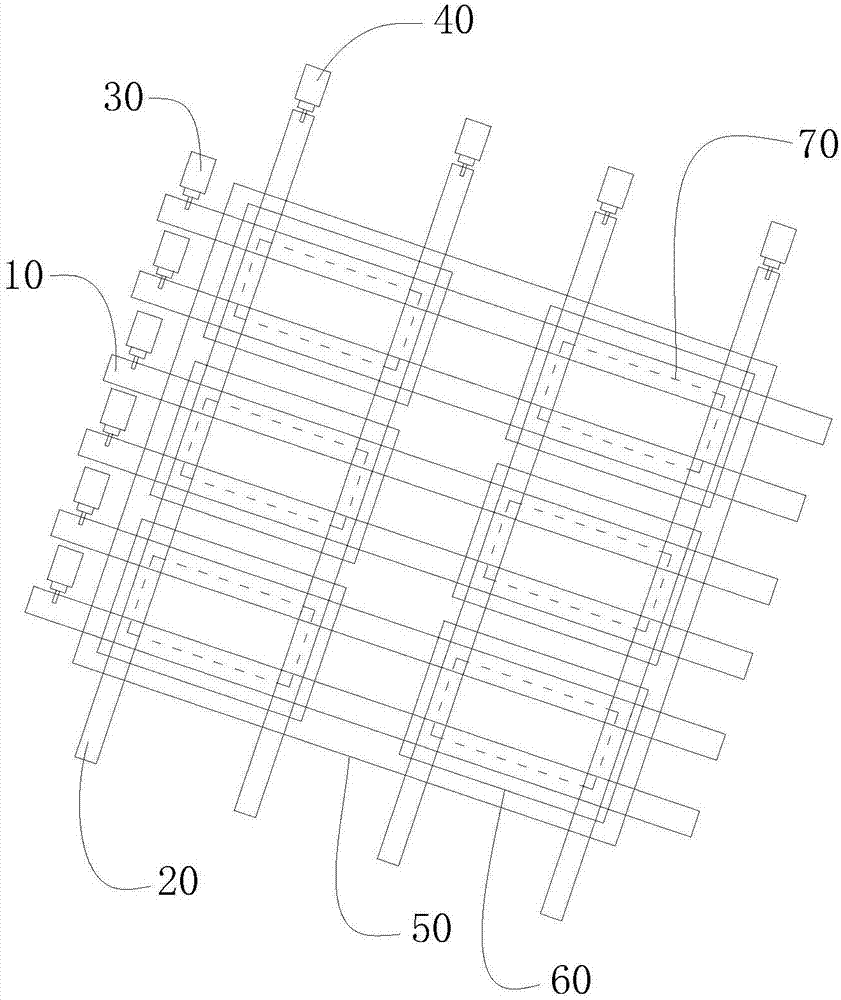

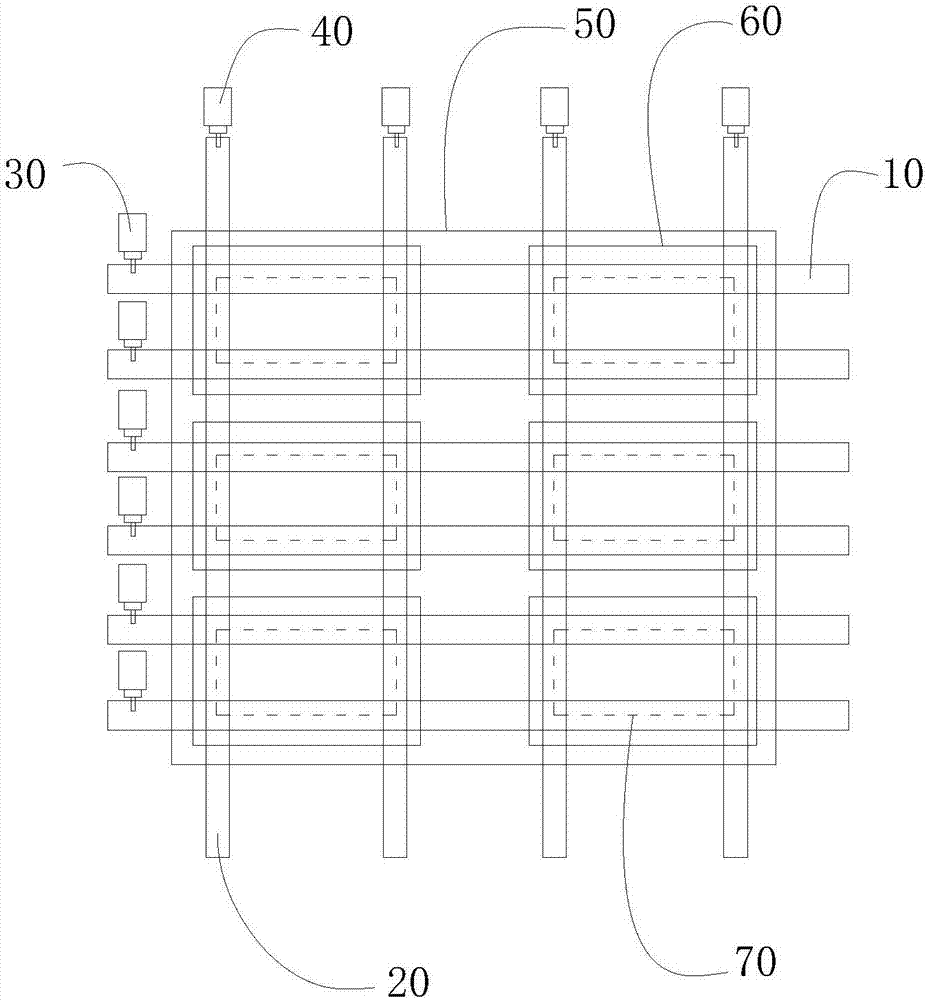

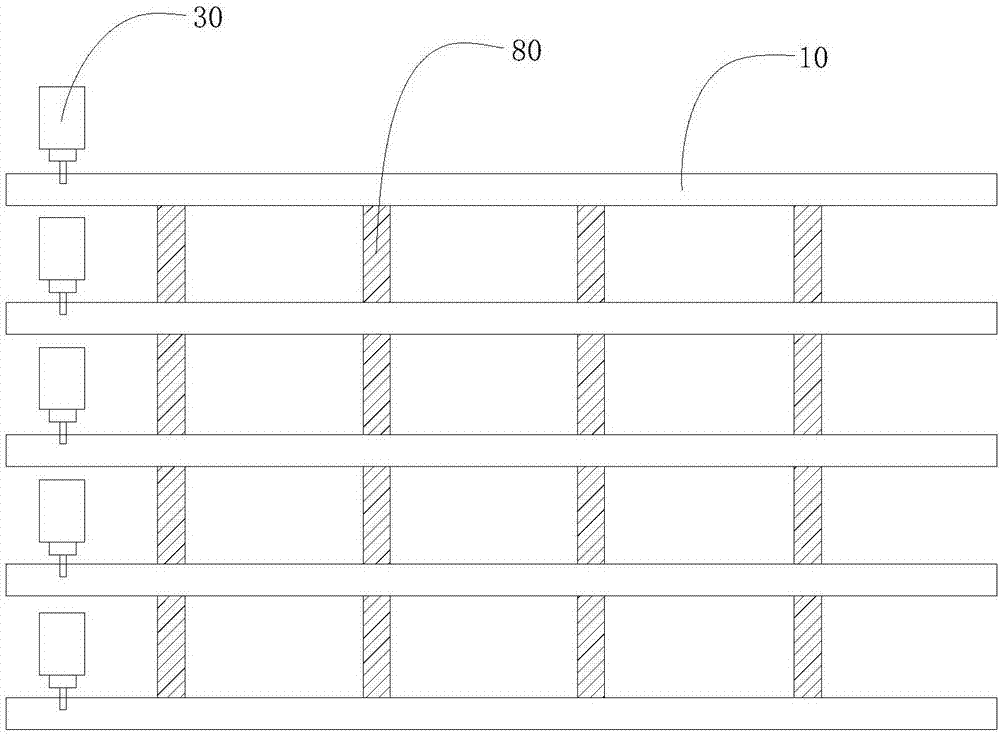

[0035] The basic idea of the present invention is: Compared with ordinary glass substrate sealant coating equipment, the sealing sealant coating device of the present invention mainly includes a trajectory control mechanism that restricts the coating trajectory on the sealant coating mechanism. The trajectory control mechanism is used to synchronize the alignment with the substrate to be coated 60 carried on the large glass plate 50, wherein four corners of the large glass plate 50 are provided with induction marks 200, such as Figure 5 Shown. The end of the trajectory control mechanism is provided with a sensing part 100 and a control part (not marked in the figure). The sensing part 100 can sense the deflection angle and position of the sensing mark 200 in real time, and send the signal to the control part. The control unit then controls the trajectory control mechanism and the substrate to be coated 60 to be aligned and deflected synchronously. If the incoming direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com