The production method of pearl sand

A production method, the technology of pearl sand, applied in the field of foundry sand, can solve the problems of heavy environmental pollution, easy to break when heated, etc., and achieve the effects of improving the working environment, reducing foundry waste, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A production method of pearl sand, comprising material selection, high-temperature melting, granulation, and screening, wherein,

[0033] Material selection: choose aluminum ore with a mass fraction of aluminum oxide above 60%;

[0034] High-temperature melting: adding the aluminum ore to an electric arc furnace, heating the aluminum ore to above 2000 degrees Celsius to melt;

[0035] Granulation: Apply air pressure to the molten liquid flowing out of the electric arc furnace to crush and cool the liquid raw material to obtain coarse pearl sand;

[0036] Sieving: Sieve the coarse pearl sand according to the particle size to obtain the pearl sand product.

[0037] By controlling the air pressure, the liquid raw material is crushed and cooled by strong wind to obtain spherical or nearly spherical sand particles with smooth surface.

Embodiment 2

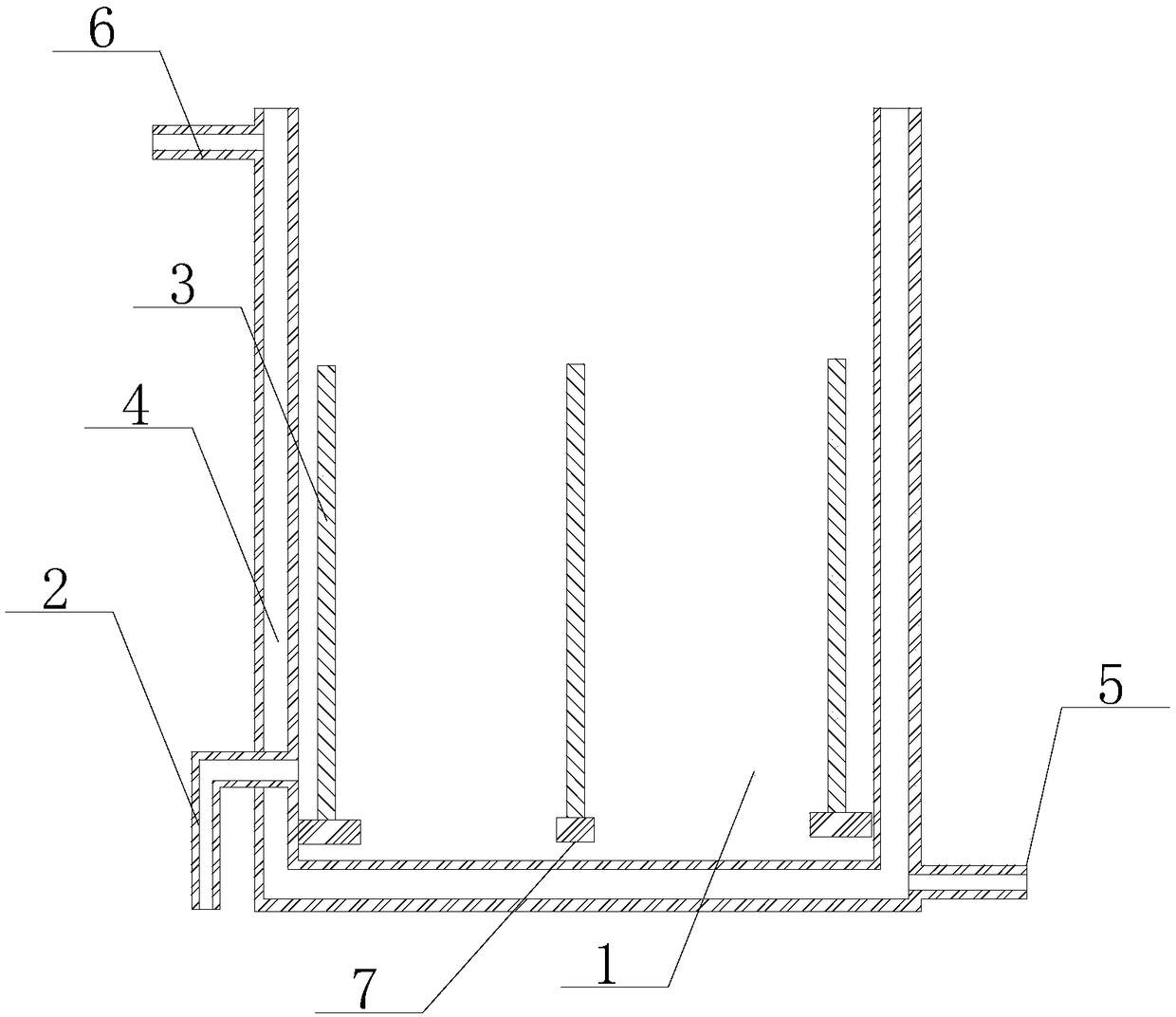

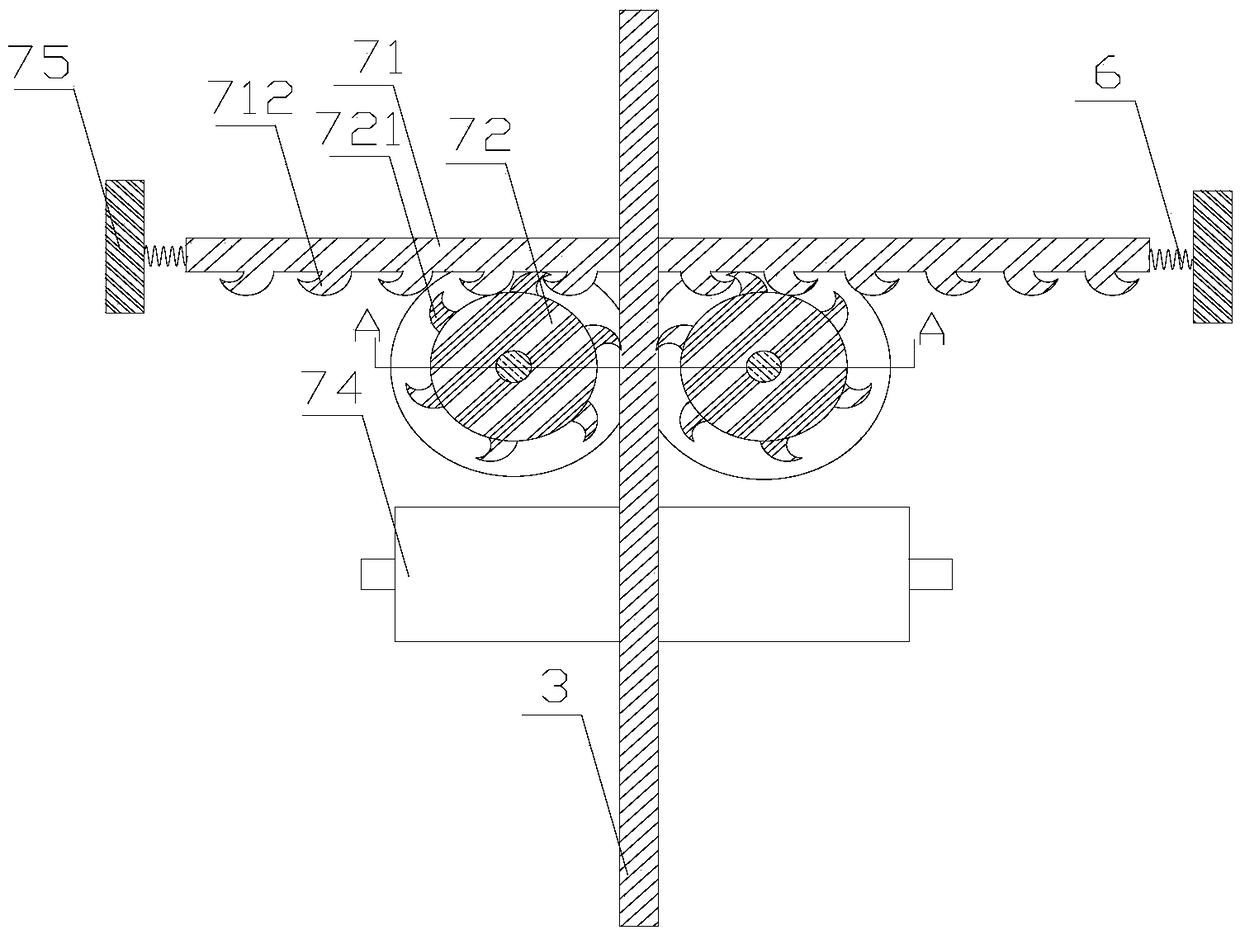

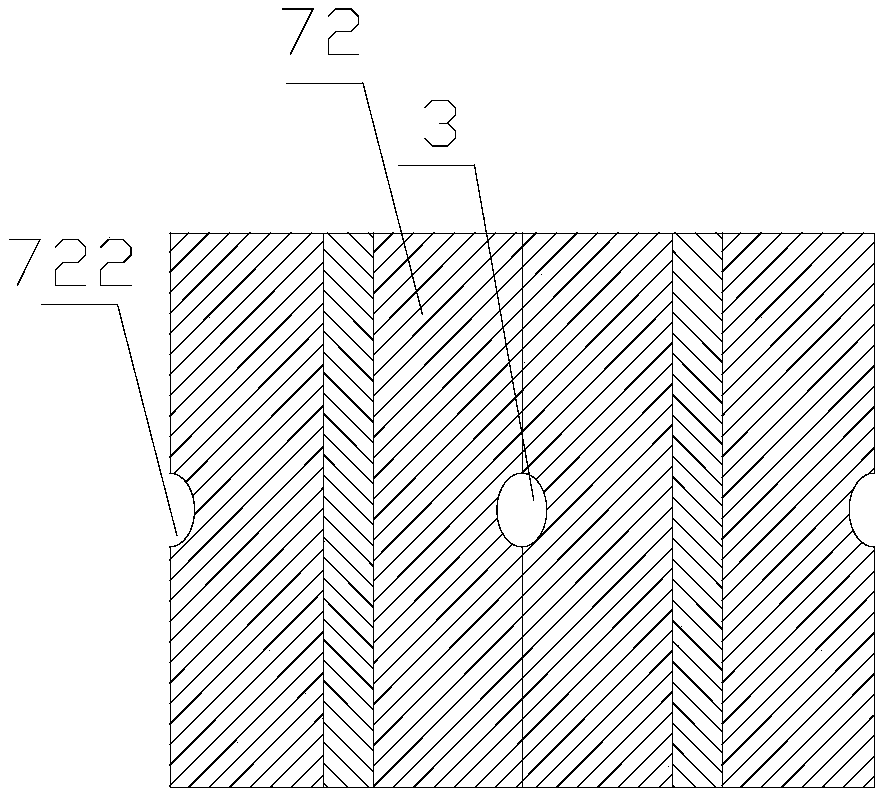

[0039] The present embodiment further defines on the basis of embodiment 1: figure 1 It is the electric arc furnace used in this embodiment. The electric arc furnace uses three-phase alternating current as the power supply. The top of the furnace chamber 1 of the electric arc furnace is open, and the bottom side wall is provided with a liquid outlet 2. There are three holes in the furnace chamber 1 that pass through the furnace chamber. 1 side wall and vertically arranged electrodes 3, the electrodes 3 are all electrically connected to the power supply, compared with the traditional horizontally arranged electrodes 3, the heating volume is larger, which is conducive to the full mixing of materials in the furnace cavity 1, and the obtained pearls The physical and chemical properties of sand products are more uniform, less affected by the differences in the raw material composition of each batch of aluminum ore.

Embodiment 3

[0041] This embodiment is further defined on the basis of Embodiment 2: the projection of the three electrodes 3 on the horizontal plane is triangular, the top of the electrodes 3 is located at 1 / 2-2 / 3 of the height of the furnace cavity 1, and the bottom is higher than Bottom of furnace chamber 1. The electrode 3 is located below the liquid level of the furnace chamber 1 to heat the molten aluminum ore. There is a cylinder on the upper part of the furnace chamber 1 to enter the solid aluminum ore of Lu Qiang for preheating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com