Automatic dust-collecting grinding tool for diesel engine

A diesel engine and automatic dust collection technology, which is applied in the direction of grinding machines, manufacturing tools, grinding racks, etc., can solve the problems of uneven diesel engine surface, unsatisfactory engine surface grinding, and damaged engine shell surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

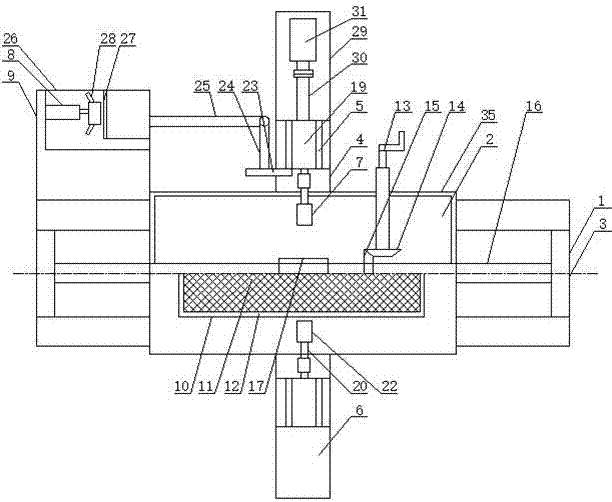

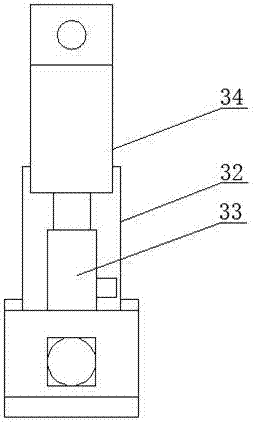

[0019] refer to Figure 1 to Figure 2 , the present embodiment provides an automatic dust-absorbing diesel engine grinding tool, including a support frame 1, a positioning bed body 2, a bed driving device 3, a grinding tool support frame 4, a lifting device 5, a moving device 6, a grinding device 7, a suction Dust device 8, dust box 9, described supporting frame 1 is provided with moving guide rail, described moving guide rail is provided with described positioning bed body 2, and described positioning bed body 2 is provided with positioning groove 10, and described positioning groove 10 is provided with an electromagnet 11, the electromagnet 11 is electrically connected to an external power supply through a connecting wire, an antimagnetic rubber pad 12 is provided around the positioning groove 10, a bed driving device 3 is provided on the positioning bed body 2, Both sides of the positioning bed body 2 are provided with a grinding tool support frame 4, and a moving device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com