Preparation process and preparation system of swelled fishplate and swelled fishplate

A preparation process and technology of a preparation system are applied in the field of preparation systems, bulging fishplates, and bulging fishplates, which can solve the problems of non-conductivity and non-magnetic conductivity, and achieve high work efficiency, light weight, and dynamic resistance. Strong impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

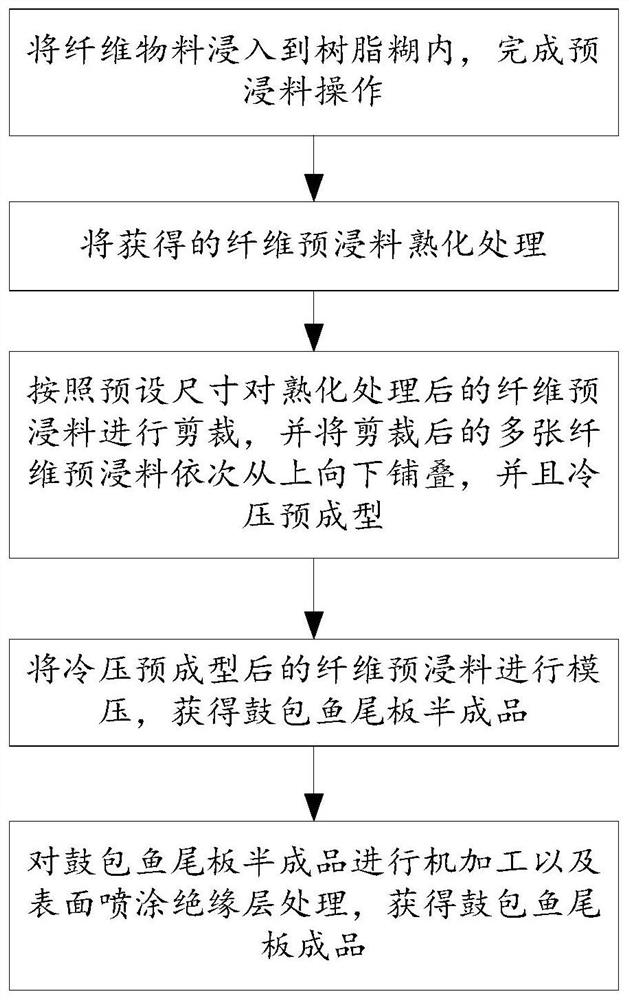

[0041] see figure 1 As shown, the embodiment of the present application provides a preparation process of a bulging fishplate, comprising the following steps:

[0042] Step 100, immerse the fiber reinforced material into the resin paste to complete the prepreg operation (note that the fiber reinforced material can be selected as glass fiber fabric or glass fiber filament, etc. Of course, the type and state of the fiber reinforced material are not limited to the above) ;

[0043] Step 200, aging the obtained fiber prepreg;

[0044] Step 300, cutting the cured fiber prepregs according to the preset size, laying up the cut fiber prepregs from top to bottom in sequence, and cold pressing the preforms;

[0045] Step 400, molding the cold-pressed preformed fiber prepreg to obtain a semi-finished bulging fishplate;

[0046] Step 500 , machining and spraying an insulating layer on the semi-finished product of the bulging fishplate to obtain a finished product of the bulging fishpla...

Embodiment 2

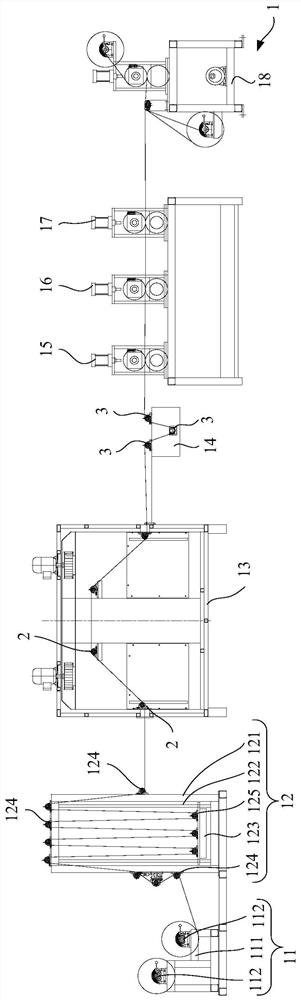

[0063] The embodiment of the present application also provides a system for preparing a swollen fishplate. The swollen fishplate preparation process described in the first embodiment above is used to produce a swollen fishplate. Therefore, it has all the beneficial technical effects of the system.

[0064] In this embodiment, preferably, the preparation system of the bulging fishplate includes: a prepreg device 1, a curing device, a first cutting device, a cold press preforming device, a molding device, a second cutting device and a spraying device, the above The device can especially be installed in a dust removal workshop with constant temperature and humidity to avoid the influence of dust and moisture in the external environment on the product and improve the quality and stability of the product; (not shown in the figure)

[0065] The above device can be used to complete the following operations, and then produce the required composite insulation bulging fishplate:

[0066...

Embodiment 3

[0098] The embodiment of the present application also provides a bulging fishplate, which is prepared based on the method for preparing the bulging fishplate described in the above-mentioned embodiment 1 and the preparation system for the bulging fishplate described in the second embodiment. Therefore, it has All beneficial technical effects of the method and the system.

[0099] In this embodiment, preferably, the bulging fishplate includes the following components by mass percentage: two-component polyurethane resin paste: 30%-45%, fiber reinforced material such as fiber braid: 65%-70%.

[0100] According to the above description, it can be seen that the bulging fishplate with the above composition content is added with fiber reinforced materials, which has high strength, strong dynamic impact resistance, and good toughness, but is light in weight, easy to install, and saves skylight resources. In addition, due to the addition of Resin makes the bulge fishplate also have agi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com