In-situ stretching method for evaluating crack propagation of prefabricated notch high-temperature nickel-based alloy

An in-situ stretching, nickel-based alloy technology, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Problems such as the indetermination of the initiation location, to achieve the effect of engineering value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

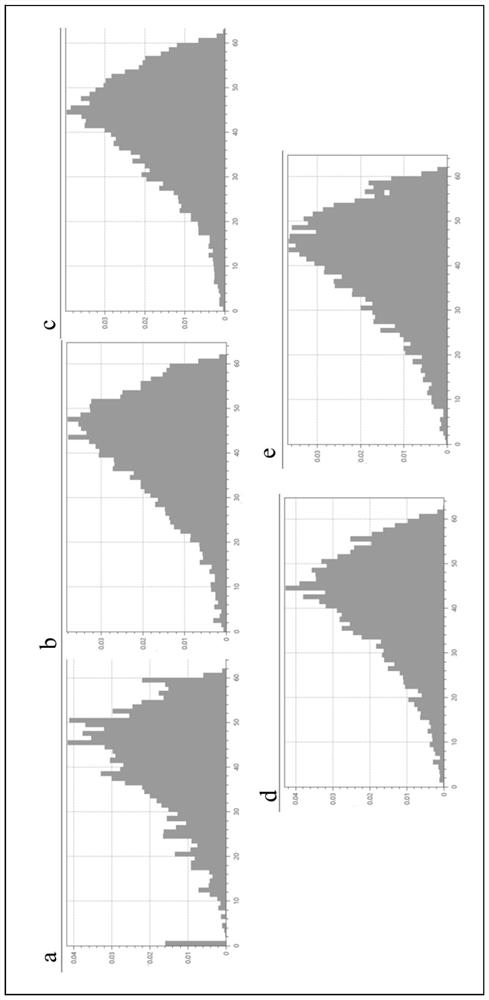

[0034] The method provided by the invention can evaluate the crack propagation of the high-temperature nickel-based alloy with pre-cracks when it is stretched in situ by SEM / EBSD at high temperature (350°C-900°C). Specifically, it includes: the change of microstructure in the vicinity of the crack, the change of misorientation angle distribution, and the change of strain distribution during the crack propagation process.

[0035] The specific steps are:

[0036] 1. Sample processing:

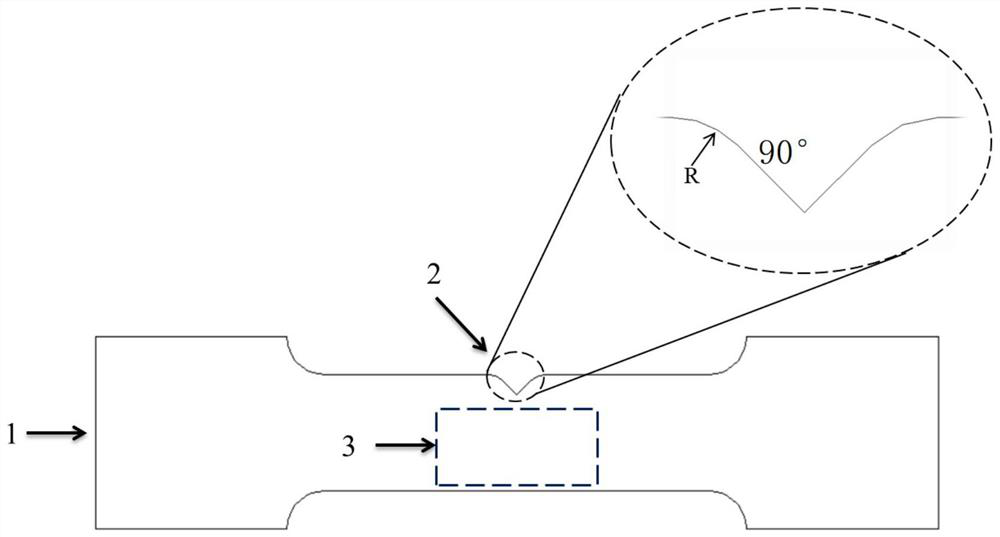

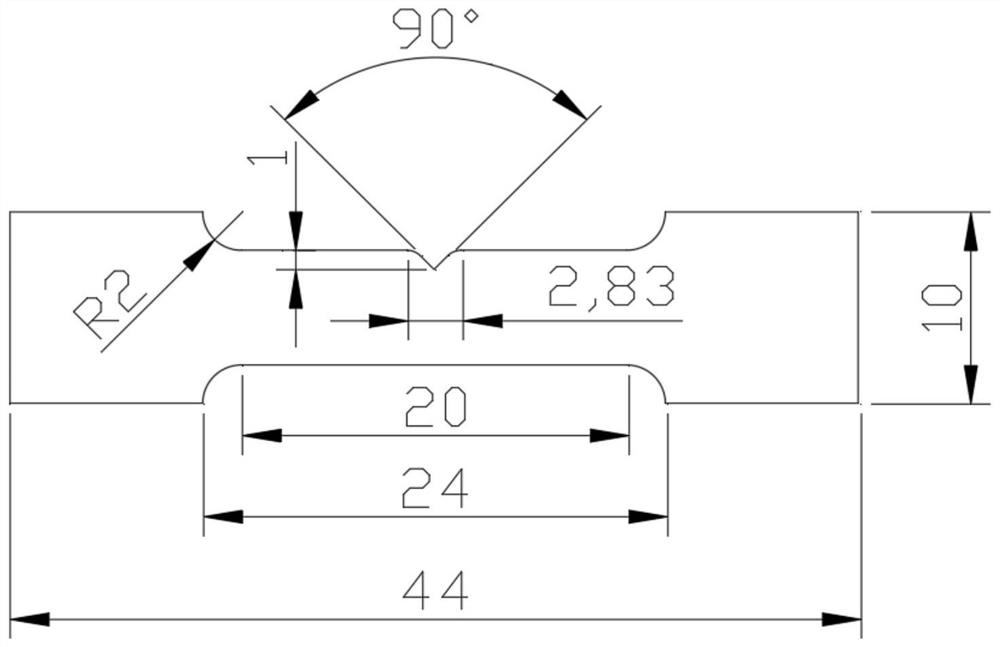

[0037] (1) The high-temperature nickel-based alloy sheet is figure 2 The size is machined into the sample, and the prefabricated notch is in the center of the sample; by figure 1 It can be seen that the two sides of the width direction of the in-situ tensile sample 1 with a notch are parallel to each other, and a notch 2 is prefabricated on one side, the angle bisector of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com