Hexanitrohexaazaisowurtzitane and 1-methyl-3, 4, 5-trinitro pyrazole eutectic explosive and rapid preparation method thereof

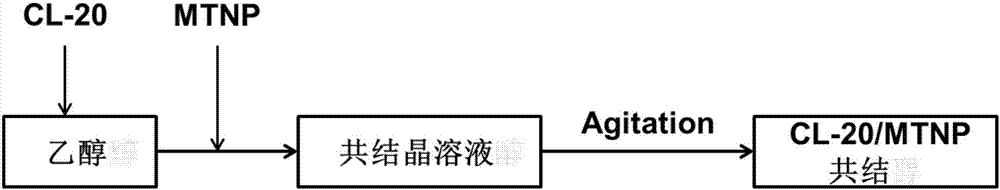

A co-crystal explosive, fast technology, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive composition, explosives processing equipment, explosives, etc., can solve the problem of rapid preparation of CL-20/MTNP co-crystal explosive No public literature report and other problems, to achieve the effect of mild preparation conditions, convenient operation and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] At room temperature, add 50ml of absolute ethanol into a three-necked flask, add 0.1095g of CL-20, heat up to 20°C, stir and dissolve CL-20, then add 0.0543g of MTNP, when CL-20 and MTNP are completely dissolved, a co-crystal is obtained solution. Continue to stir the co-crystal solution at 20°C, and then adjust the stirring speed to 50 rpm. During the stirring process, the co-crystal begins to precipitate, and the solution becomes turbid. Filter and dry to obtain micron-sized CL-20 / MTNP co-crystal explosives.

Embodiment 2

[0029] At room temperature, add 70ml of absolute ethanol into a three-necked flask, add 0.2175g of CL-20, heat up to 35°C, stir and dissolve CL-20, then add 0.1085g of MTNP, when CL-20 and MTNP are completely dissolved, a co-crystal is obtained solution. Continue to stir the co-crystal solution at 35°C, and then adjust the stirring speed to 150 rpm. During the stirring process, the co-crystal begins to precipitate, and the solution becomes turbid. Filter and dry to obtain micron-sized CL-20 / MTNP co-crystal explosives.

Embodiment 3

[0031] At room temperature, add 100ml of absolute ethanol into a three-necked flask, add 0.438g of CL-20, heat up to 40°C, stir and dissolve CL-20, then add 0.217g of MTNP, when CL-20 and MTNP are completely dissolved, a co-crystal is obtained solution. Continue to stir the co-crystal solution at 40°C, and then adjust the stirring speed to 200 rpm. During the stirring process, the co-crystal begins to precipitate, and the solution becomes turbid. Filter and dry to obtain micron-sized CL-20 / MTNP co-crystal explosives.

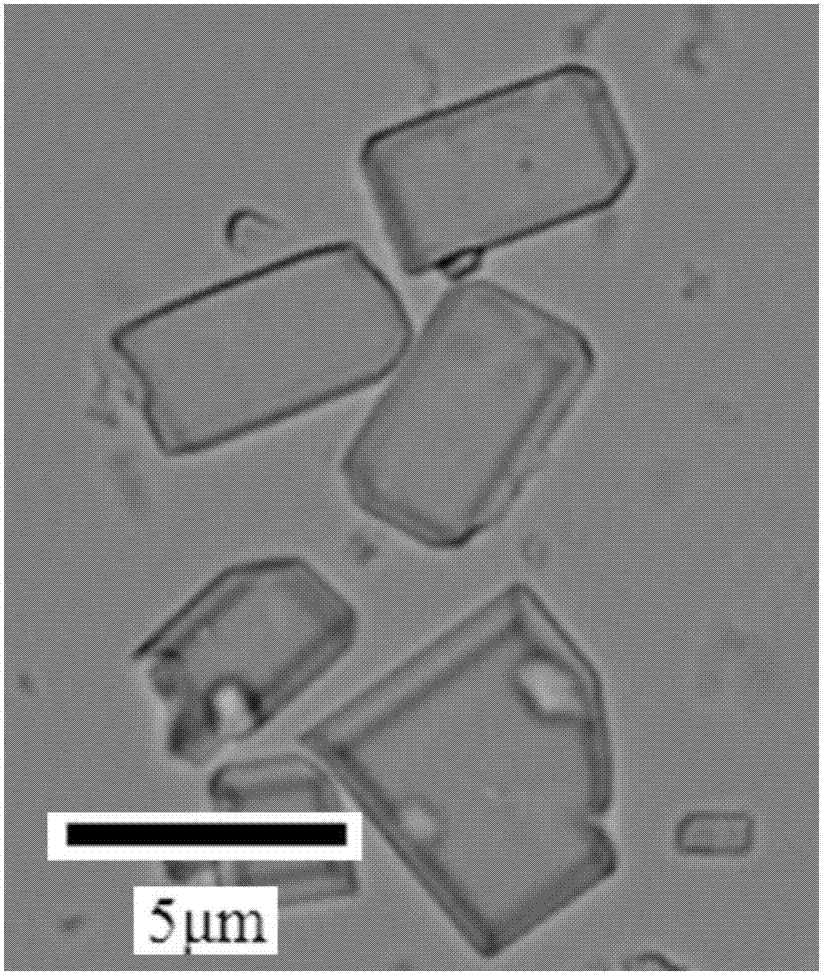

[0032] Such as figure 2 As shown, according to another embodiment of the present invention, this embodiment discloses the CL-20 / MTNP eutectic explosive prepared by the rapid preparation method of the above-mentioned embodiment CL-20 and MTNP eutectic explosive. figure 2 The crystal morphology of the CL-20 / MTNP eutectic explosive of the present invention is shown. Depend on figure 2 It can be seen that the CL-20 / MTNP eutectic explosive in this example is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com