A kind of environment-friendly reclaimed rubber and its production method

A reclaimed rubber and environmentally friendly technology, applied in the field of reclaimed rubber production, can solve the problems of large pollution, unpleasant smell of reclaimed rubber, poor physical and mechanical properties of reclaimed rubber, etc., and achieve good tensile strength and elongation at break, odor Small, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

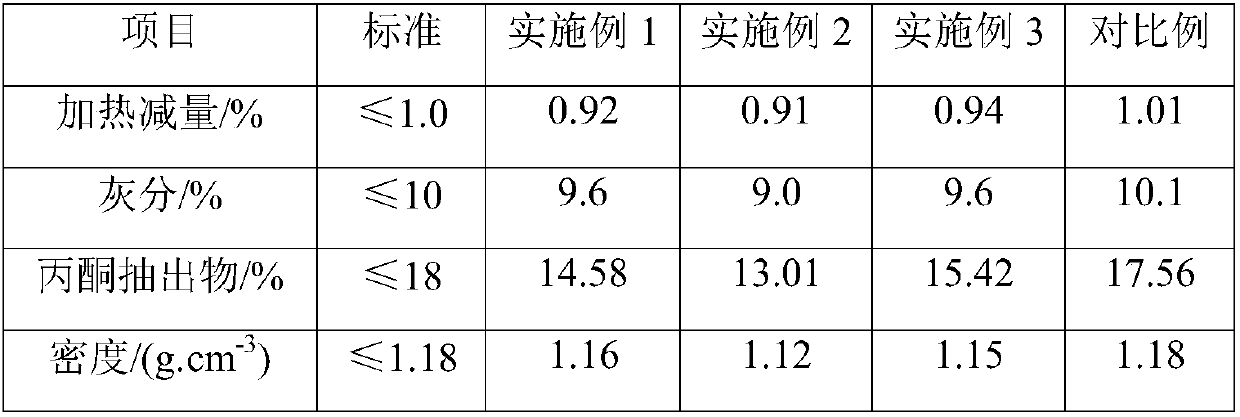

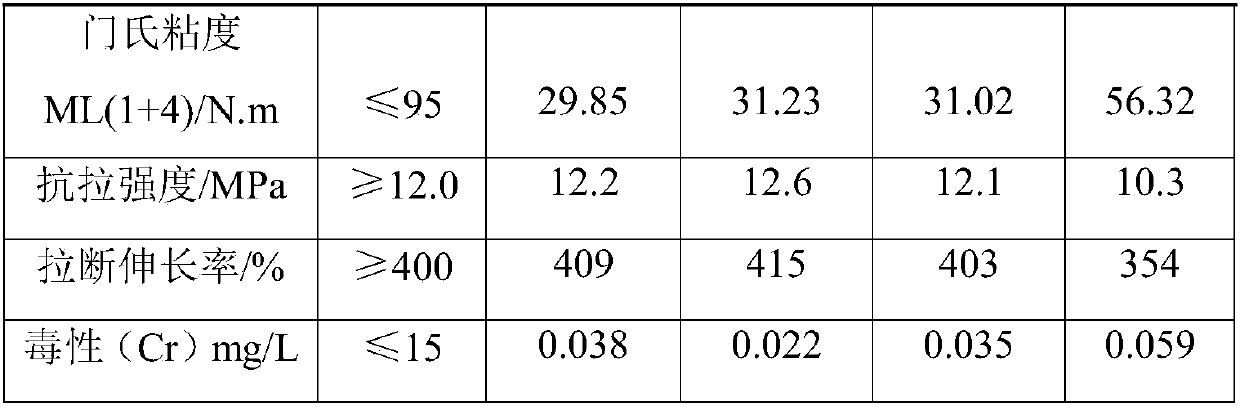

Examples

Embodiment 1

[0027] An environmentally friendly reclaimed rubber is made from waste rubber powder and auxiliary materials in a weight ratio of 8:3;

[0028] The auxiliary material is made from the following raw materials in parts by weight: 20 parts of palm oil, 6 parts of tall oil, 10 parts of softening agent, 4 parts of activator, 2 parts of ethylene glycol ethyl ether acetate, 10 parts of oxidized polyethylene wax , 1 part of stearic acid, 3 parts of sodium tripolyphosphate and 5 parts of paper sludge ash.

[0029] As mentioned, the softener is obtained by mixing diethanol monoisopropanolamine maleate compound and diethanol monoisopropanolamine in a weight ratio of 1:1.5.

[0030] Described, diethanol monoisopropanolamine maleate compound is prepared by the following method: add diethanol monoisopropanolamine and maleic anhydride in the reactor, add catalyst, depressurize to 0.4MPa, heating, the temperature is controlled at 100°C, the system is maintained at a constant temperature, and...

Embodiment 2

[0041] An environmentally friendly reclaimed rubber, which is made from waste rubber powder and auxiliary materials in a weight ratio of 10:2;

[0042] The auxiliary material is made from the following raw materials in parts by weight: 30 parts of palm oil, 5 parts of tall oil, 8 parts of softener, 3 parts of activator, 3 parts of ethylene glycol ether acetate, 6 parts of oxidized polyethylene wax , 3 parts of stearic acid, 2 parts of sodium tripolyphosphate and 4 parts of paper sludge ash.

[0043] As mentioned, the softener is obtained by mixing diethanol monoisopropanolamine maleate compound and diethanol monoisopropanolamine in a weight ratio of 1:2.

[0044] A production method of environmentally friendly reclaimed rubber is prepared by the following steps:

[0045] 1) After the waste tires are cut and separated from the sidewall, the top of the tire is cut into pieces and crushed to obtain 26 mesh waste rubber powder;

[0046] 2) Mix the waste rubber powder and auxilia...

Embodiment 3

[0051] An environmentally friendly reclaimed rubber is made from waste rubber powder and auxiliary materials in a weight ratio of 12:1.5;

[0052] The auxiliary material is made from the following raw materials in parts by weight: 40 parts of palm oil, 4 parts of tall oil, 5 parts of softener, 1 part of activator, 4 parts of ethylene glycol ether acetate, 3 parts of oxidized polyethylene wax , 4 parts of stearic acid, 1 part of sodium tripolyphosphate and 3 parts of paper sludge ash.

[0053] As mentioned, the softener is obtained by mixing diethanol monoisopropanolamine maleate compound and diethanol monoisopropanolamine in a weight ratio of 1:3.

[0054] A production method of environmentally friendly reclaimed rubber is prepared by the following steps:

[0055] 1) After the waste tires are cut and separated from the sidewall, the top of the tire is cut into pieces and crushed to obtain 26 mesh waste rubber powder;

[0056]2) Mix the waste rubber powder and auxiliary mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com