Euglena gracilis culturing method

A technology of Euglena teniculata and its cultivation method, which is applied in the field of cultivating Euglena tenabilis, can solve the problems of long lag period, waste of glucose concentration, and lower culture yield, and achieve high yield utilization and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Aerotrophic cultures:

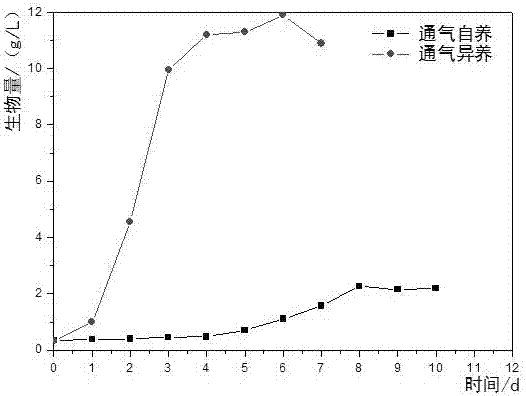

[0023] In a 1000mL culture bottle, aerated autotrophic culture was carried out under the following conditions: the inoculation density of Euglena gracilis was 0.33g / L; the composition of the heterotrophic medium included: NaNO 3 1.5g / L, K 2 HPO 3 0.3g / L, KH 2 PO 3 0.2g / L, MgSO 4 ·7H 2 O 0.1g / L, TE trace element solution 1mL / L, the rest is water, and the formula of TE solution is H 3 BO 3 2.81g / L, MnCl 2 4H 2 O1.82g / L, ZnSO 4 ·7H 2 O 0.23g / L, Na 2 MoO 4 2H 2 O 0.34g / L, CuSO 4 ·5H 2 O 0.05g / L and Co(NO 3 ) 2 ·6H 2 O 0.06g / L; culture temperature 28°C, air flow 1.0L / min, add 0.05% silicone defoamer. The results are shown in Figure 1.

[0024] Aerated Heterotrophic Culture with Additional Carbon Source Glucose

[0025] In a 1000mL culture bottle, aerated heterotrophic culture was carried out with the addition of carbon source glucose. The culture conditions were: the inoculation density of Euglena gracilis was 0.33g / L; 3 1.5g / L, ...

Embodiment 2

[0028] Aerotrophic cultures:

[0029] In a 1000mL culture bottle, aerated autotrophic culture was carried out under the following conditions: the inoculation density of Euglena gracilis was 0.33g / L; the composition of the heterotrophic medium included: NaNO 3 1.5g / L, K 2 HPO 3 0.3g / L, KH 2 PO 3 0.2g / L, MgSO 4 ·7H 2 O 0.1g / L, TE trace element solution 1mL / L, the rest is water, and the formula of TE solution is H 3 BO 3 2.81g / L, MnCl 2 4H 2 O1.82g / L, ZnSO 4 ·7H 2 O 0.23g / L, Na 2 MoO 4 2H 2 O 0.34g / L, CuSO 4 ·5H 2 O 0.05g / L and Co(NO 3 ) 2 ·6H 2 O 0.06g / L; culture temperature 25°C, air volume 1.0L / min, add 0.05% silicone defoamer. The results are shown in Figure 1.

[0030] Aerated Heterotrophic Culture with Additional Carbon Source Glucose

[0031] In a 1000mL culture bottle, aerated heterotrophic culture was carried out with the addition of carbon source glucose. The culture conditions were: the inoculation density of Euglena gracilis was 0.33g / L; 3 1.5g / L...

Embodiment 3

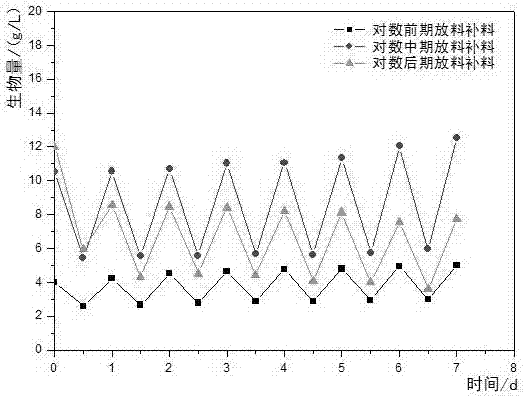

[0034] Heterotrophic culture with additional carbon source glucose aeration, feeding and rehydration culture in the early stage of the exponential phase.

[0035] In a 1000mL culture bottle, aerated heterotrophic culture was carried out with the addition of carbon source glucose. The culture conditions were: the inoculation density of Euglena gracilis was 0.33g / L; the composition of the heterotrophic medium included: glucose 20g / L, yeast powder 5g / L , K 2 HPO 3 0.3g / L, KH 2 PO 3 0.2g / L, MgSO 4 7H2O 0.1g / L, TE trace element solution 1mL / L, the rest is water, and the formula of TE solution is H 3 BO 3 2.81g / L, MnCl 2 4H2O 1.82g / L, ZnSO 4 7H2O 0.23g / L, Na 2 MoO 4 2H2O 0.34g / L, CuSO 4 ·5H 2 O 0.05g / L and Co(NO 3 ) 2 ·6H 2 O 0.06g / L; culture temperature 25--28°C, air volume 1.0L / min, add 0.05% organic silicon defoamer; start feeding 1 / 2 Euglena gracilis every day from day 1.5-2 , supplement the same amount of nutrient solution again, and continue to cultivate, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com