Braking device of fuel pressure control braking valve

A fuel pressure and braking device technology, applied in the direction of valve devices, engine components, machines/engines, etc., can solve the problems of insufficient pressure, decompression braking timeliness and insufficient stability, etc., to achieve rapid response, fast control, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

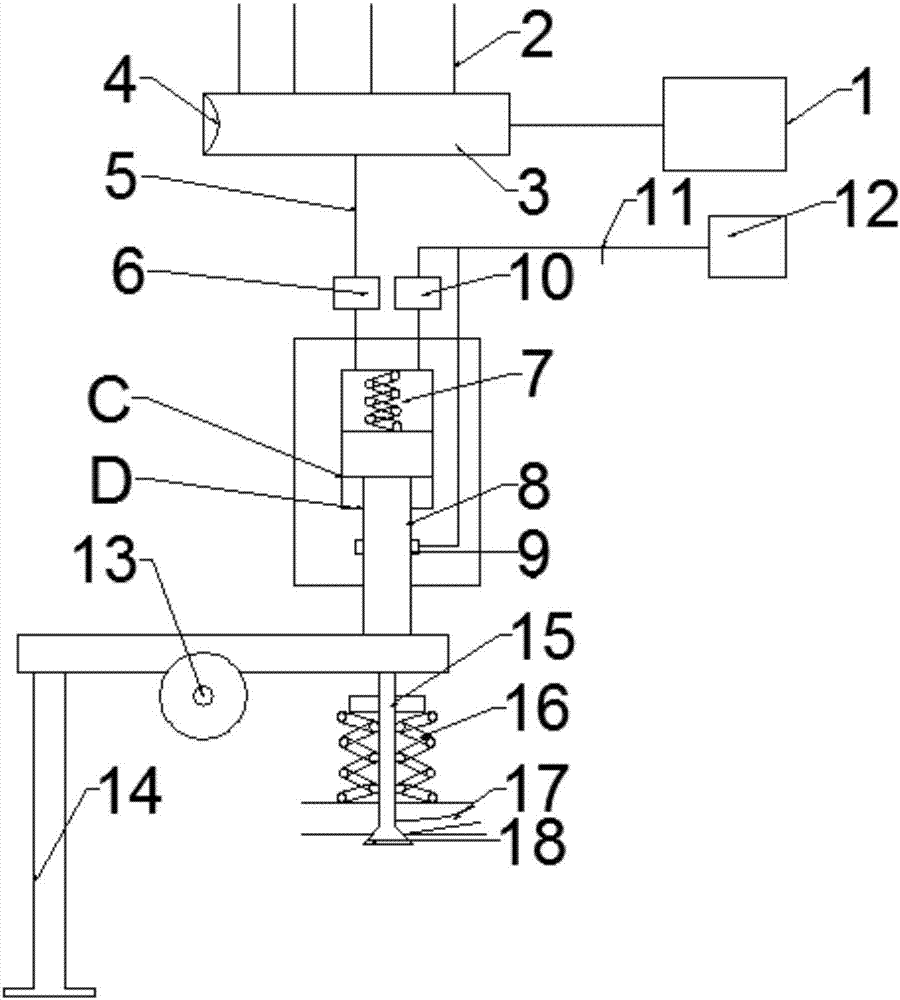

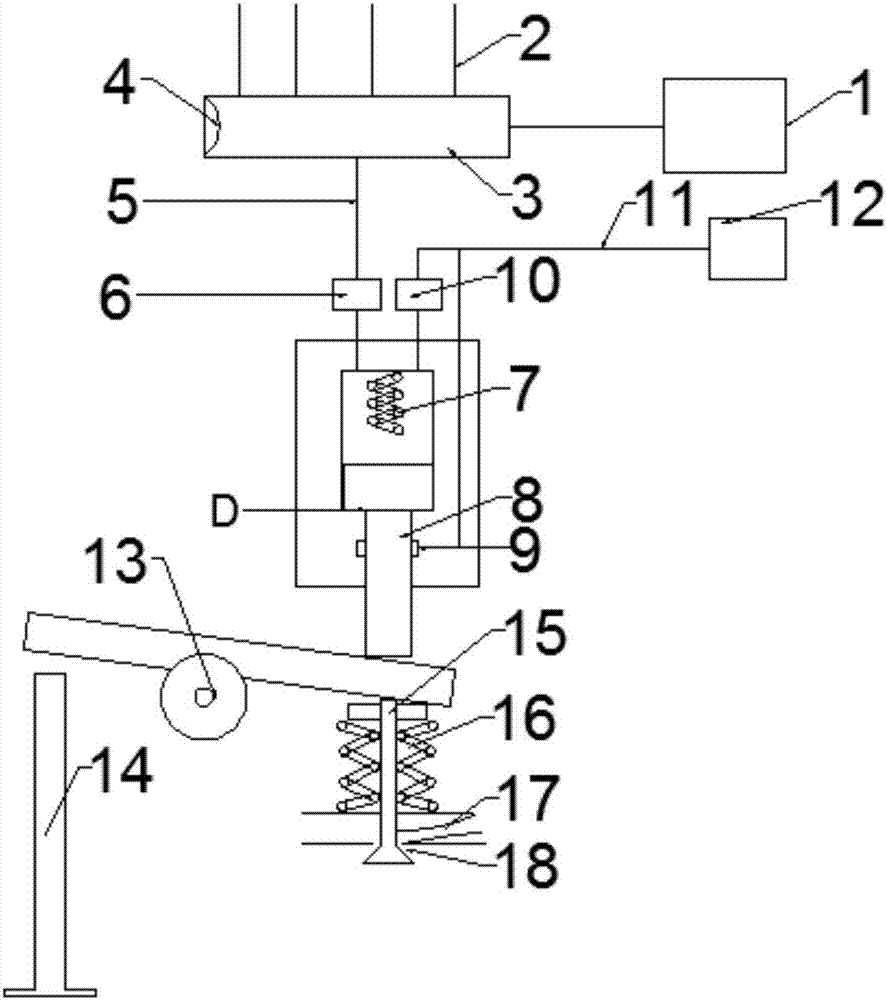

[0022] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing:

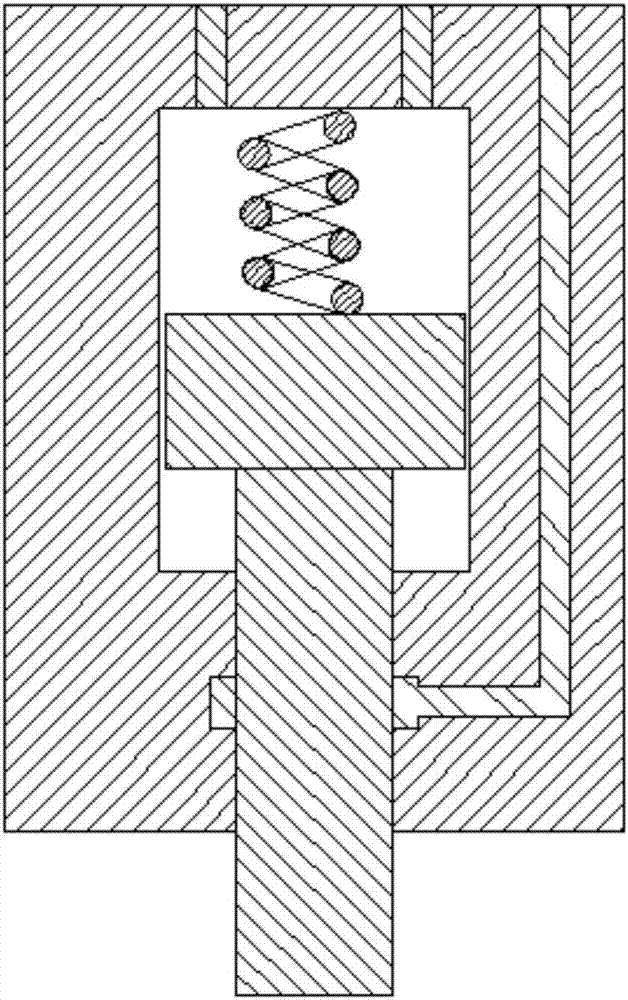

[0023] refer to figure 1 , a brake device for a fuel pressure control brake valve, comprising an oil pump 1, a fuel injection pipe 2, a high-pressure fuel rail 3, a pressure sensor 4, an oil outlet pipe 5, an oil inlet solenoid valve 6, a plunger spring 7, and a plunger coupler Part 8, low-pressure ring groove 9, drain solenoid valve 10, low-pressure oil circuit 11, fuel tank 12, rocker arm 13, tappet 14, valve tappet 15, valve spring 16, exhaust passage 17, exhaust valve 18.

[0024] The oil pump 1 communicates with the high-pressure oil rail 3, and the high-pressure oil rail 3 is provided with an oil injection pipe 2. The high-pressure oil rail 3 communicates with the cavity in the plunger pair 8 through the oil outlet pipe 5 . The fuel tank 12 communicates with the plunger 8 through the low-pressure oil circuit 11, and is used for recovering useless high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com