Limited measuring point based air conditioning system performance online detection method

A technology of an air conditioning system and a detection method, which is applied to heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

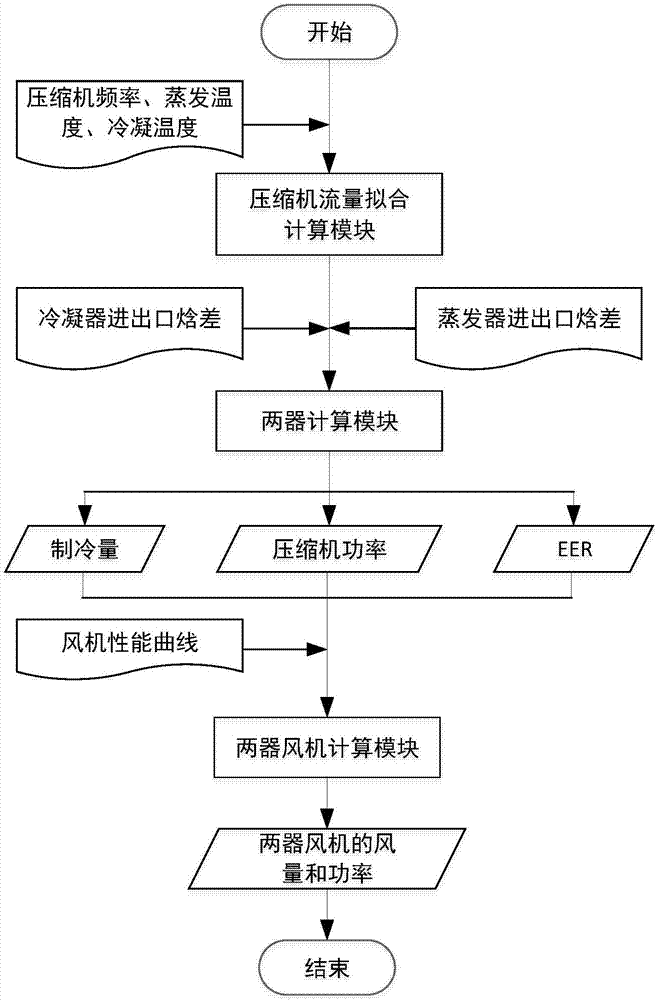

[0032] Such as figure 1 As shown, this embodiment includes the following steps:

[0033] Step 1. Arrange measuring points in the running air-conditioning system, and record the parameters of the measuring points in real time.

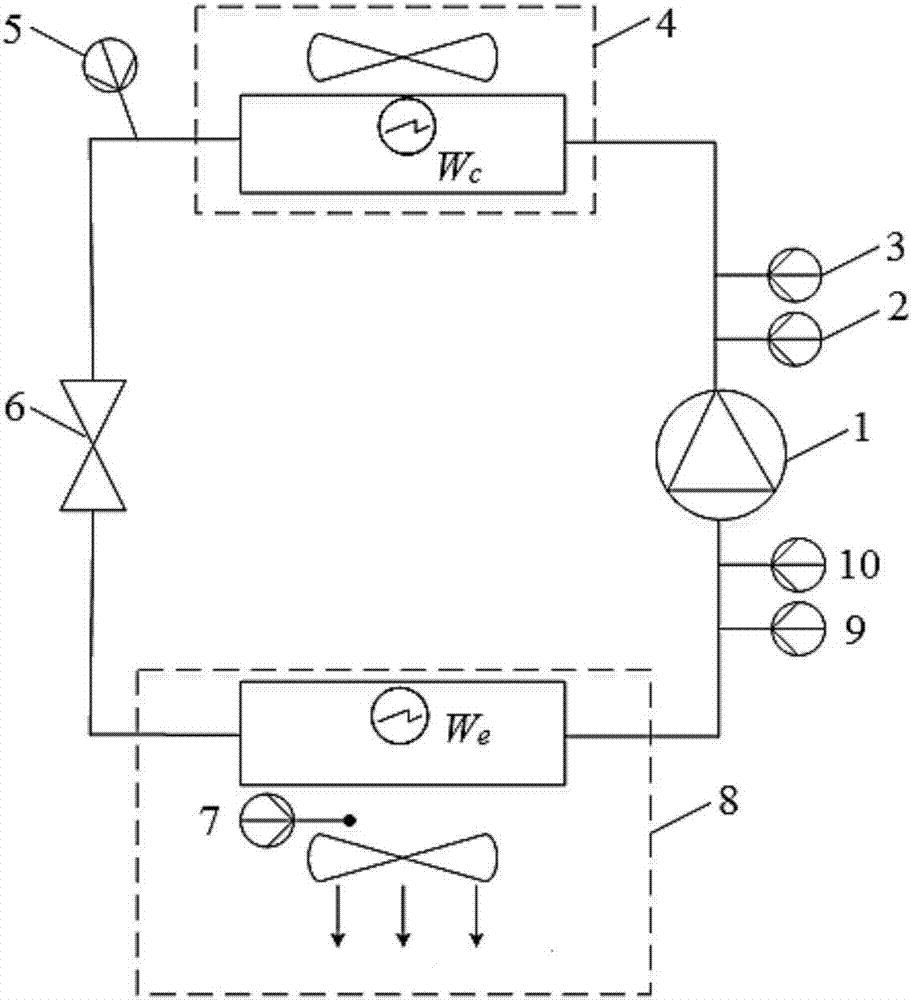

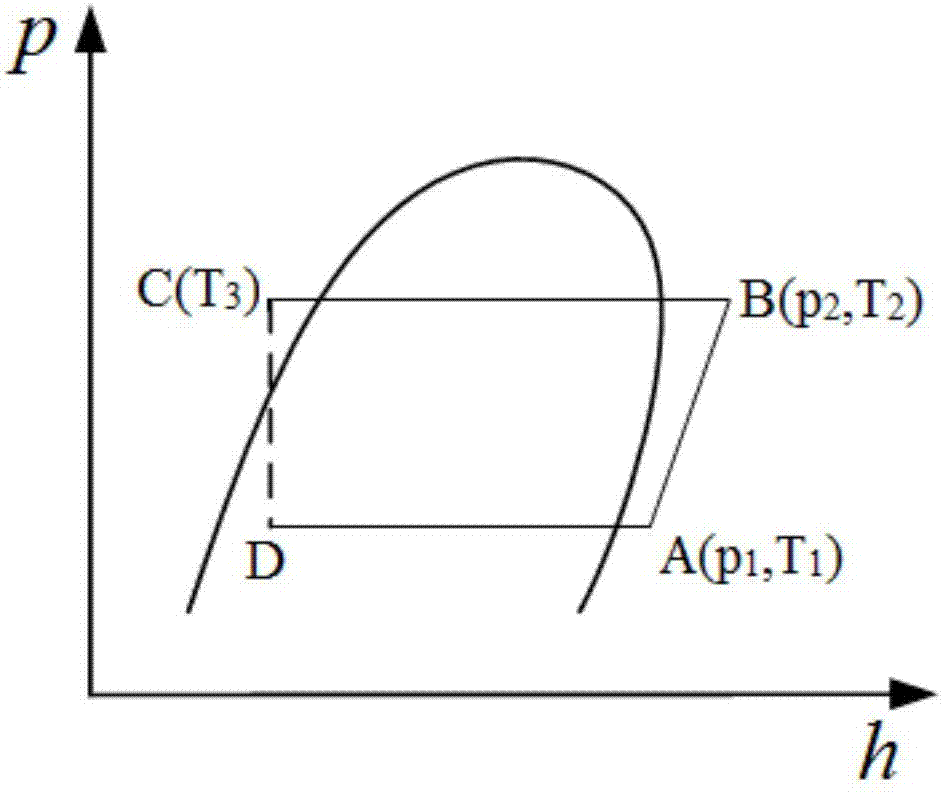

[0034] Such as figure 2 As shown, the arrangement of measuring points refers to the arrangement of compressor discharge temperature measurement points and compressor discharge pressure measurement points between the compressor and condenser of the air-conditioning system to obtain the compressor discharge temperature parameter T 0 and exhaust pressure parameter p 0 ; Arrange liquid pipe temperature measuring points at the outlet of the condenser liquid pipe to obtain the liquid pipe temperature parameter T 2 ; Arrange compressor suction temperature measuring points and compressor suction pressure measuring points between the evaporator and compressor to obtain the compressor suction temperature parameter T 1 and the inspiratory pressure parameter p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com