A kind of curved surface transition connection plate of medical equipment shell and bonding method thereof

A technology for medical equipment and transition connection, which is applied in the field of transition bonding of curved surfaces of plastic shells, can solve the problems of reduced elastic deformation capacity, damage to the shell, unsightly appearance, etc., and achieves the effects of improving integrity, convenient bonding, and reliable bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

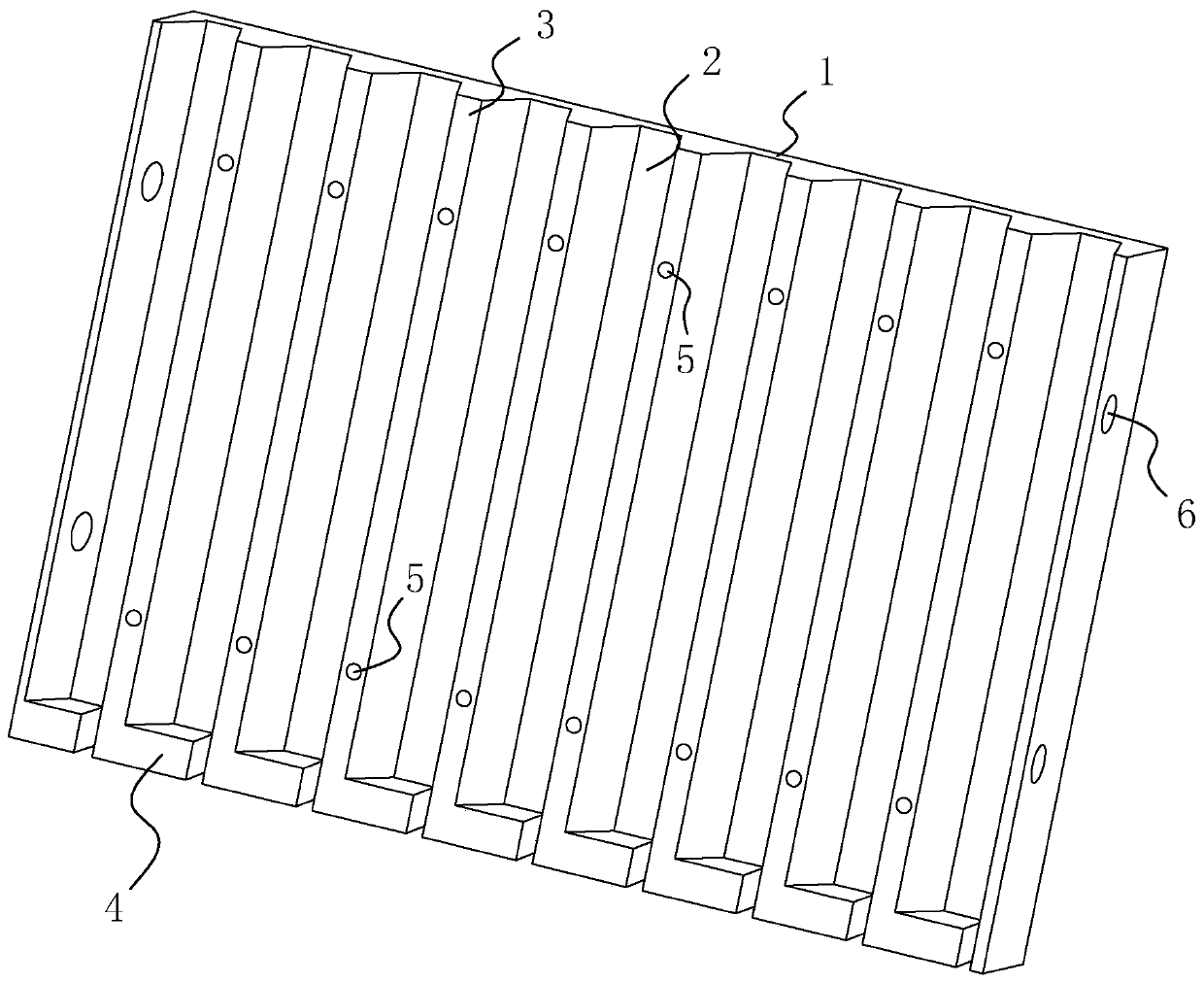

[0029] Embodiment 1: A transitional connection plate for the arc surface of a medical device shell, including a plate body 1, which is adapted to the corner arc surface of the shell bottom plate, and the corner arc surface of the shell bottom plate is generally a plane according to the transition surface of the shell bottom plate Or the inclined surface is divided into two types of transition forms: arc surface or conical surface. If the transition surface of the bottom plate of the shell is an arc surface, the shape of the corresponding plate body 1 is rectangular. If the transition surface of the bottom plate of the shell is a conical surface, Then the shape corresponding to the plate body 1 is a fan shape. When making the plate body 1, the required length of the plate body 1 is determined according to the radian of the corner arc surface of the shell bottom plate. The length of the plate body 1 generally selected is slightly longer than the shell bottom plate. The length of ...

Embodiment 2

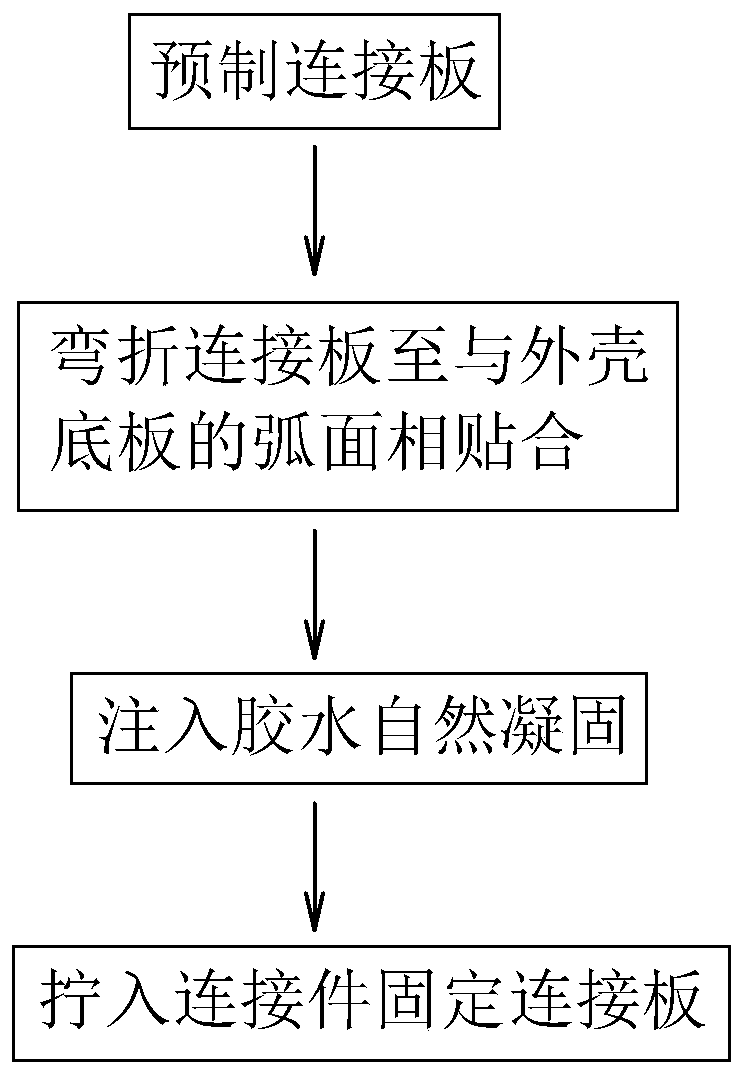

[0035] Embodiment 2: A method for transitional bonding of the curved surface of a medical device housing, including the following steps:

[0036]Step 1: Prefabricate the connection plate described in Embodiment 1 according to the length and radian of the corner arc surface of the shell bottom plate, first select a plate with a suitable thickness, and then cut out according to the length, width or radian of the corner arc surface of the shell bottom plate Appropriate size of the plate body 1, then cut the plate body 1 to form the forming groove 2, and reserve the rubber protrusion 4, and finally open the connecting hole 5 on the connecting edge 3 as required, and connect the connecting edge on both sides 3 Open the glue storage tank;

[0037] Step 2: Bend the above-mentioned connecting plate along the arc surface of the corner of the bottom plate of the shell until it fits the bottom plate of the shell, fix the bottom plate of the shell, and press the connecting plate tightly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com