Device suitable for triggered gap

A technology for triggering gaps and triggers, which is applied to circuits dedicated to spark gaps, spark gaps, spark gap components, etc. It can solve problems such as difficult conduction of the main gap, insufficient pressure in the injection chamber, and affecting the electrical performance of the trigger gap. , to achieve the effect of improving the overall mechanical strength, improving the mechanical strength of the electrode, and improving the flow capacity of the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

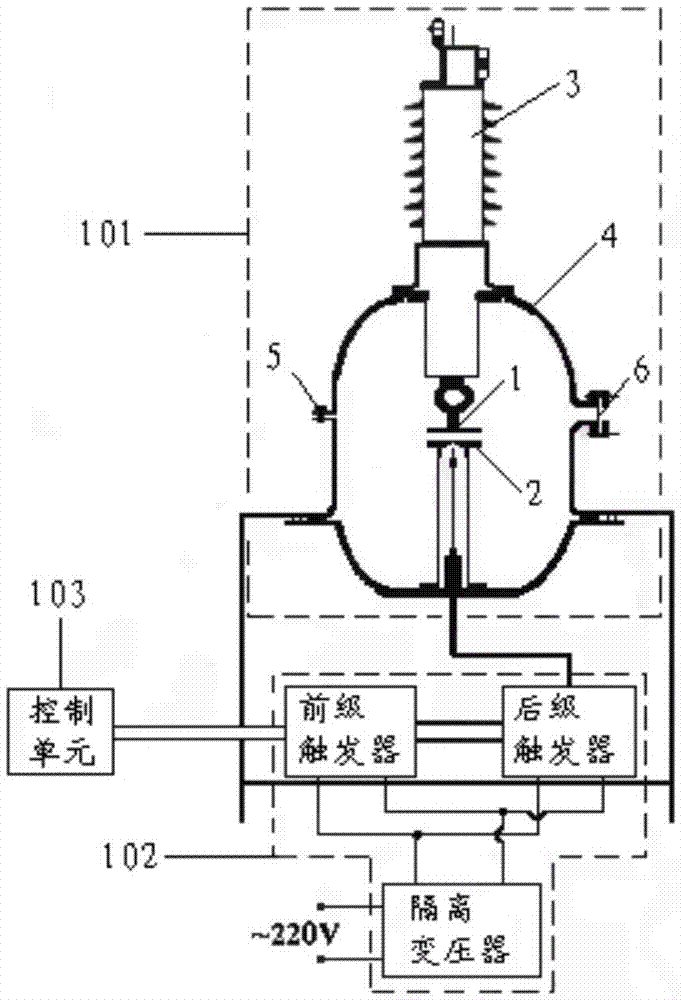

[0028] according to figure 1 As shown, the integral device of the injection trigger gap includes: a trigger gap body 101 , a trigger 102 and a control unit 103 .

[0029] The control unit 103 receives the control signal sent from the outside, converts the control signal into an optical signal, transmits it through an optical fiber, and outputs it to the trigger 102 , and controls the trigger 102 to trigger the conduction of the trigger gap body 101 .

[0030] The trigger 102 includes an isolation transformer, a pre-stage trigger and a post-stage trigger. The isolation transformer supplies power to the front-stage trigger and the rear-stage trigger respectively. After the front-stage trigger receives the trigger signal sent by the control unit 101, it outputs a pulse signal to discharge the rear-stage trigger, generates a high-voltage pulse sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com