Near-wall attaching method and near-wall attaching apparatus for preventing high temperature corrosion of water cooling wall of boiler

A high-temperature corrosion and water-cooled wall technology, which is applied in the boiler field, can solve the problems of large air consumption, influence of furnace combustion, and large influence of furnace combustion and boiler operation, and achieve the effect of reducing investment costs and reducing high-temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

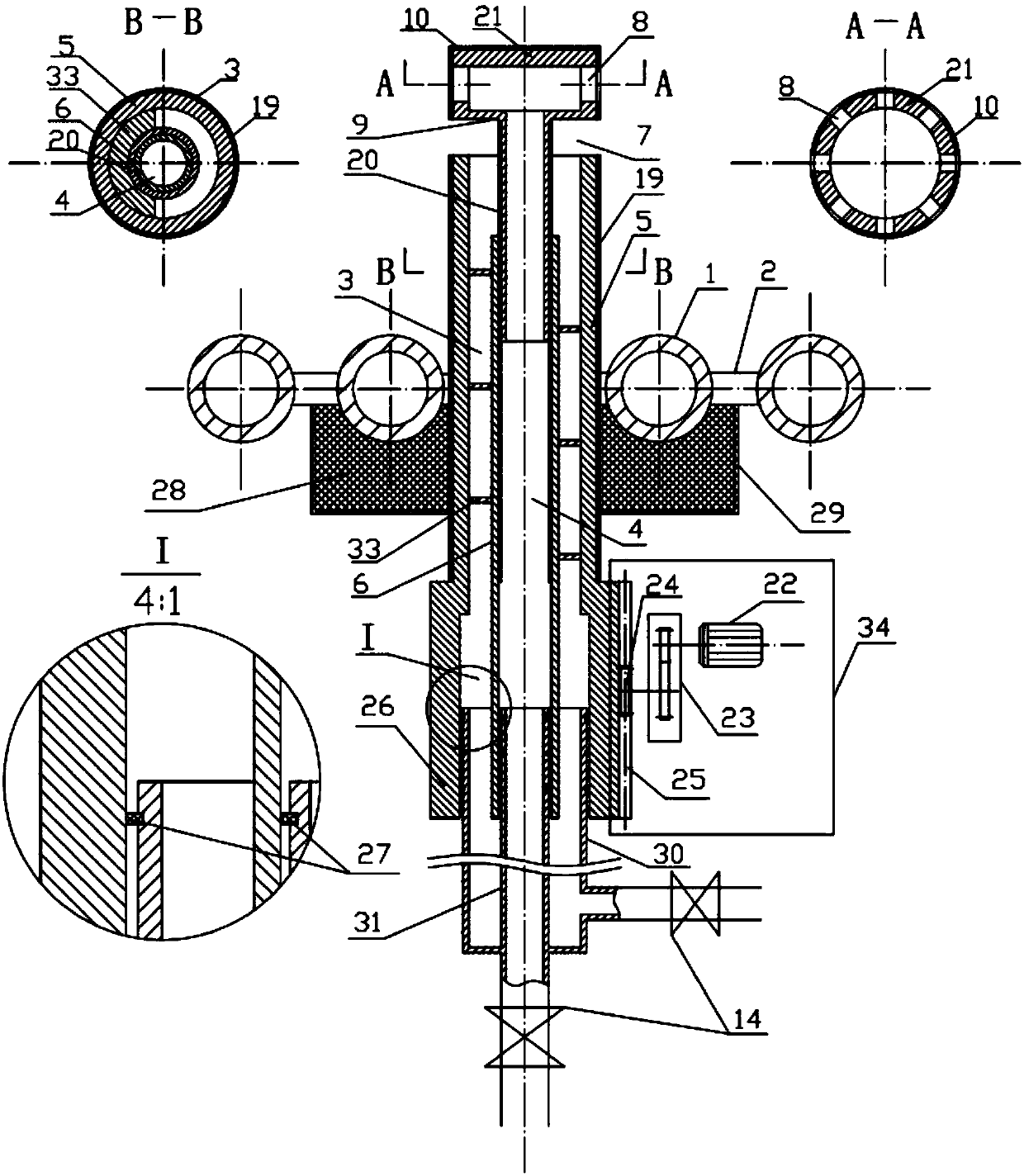

[0020] Below in conjunction with accompanying drawing, the patent of the present invention is further elaborated.

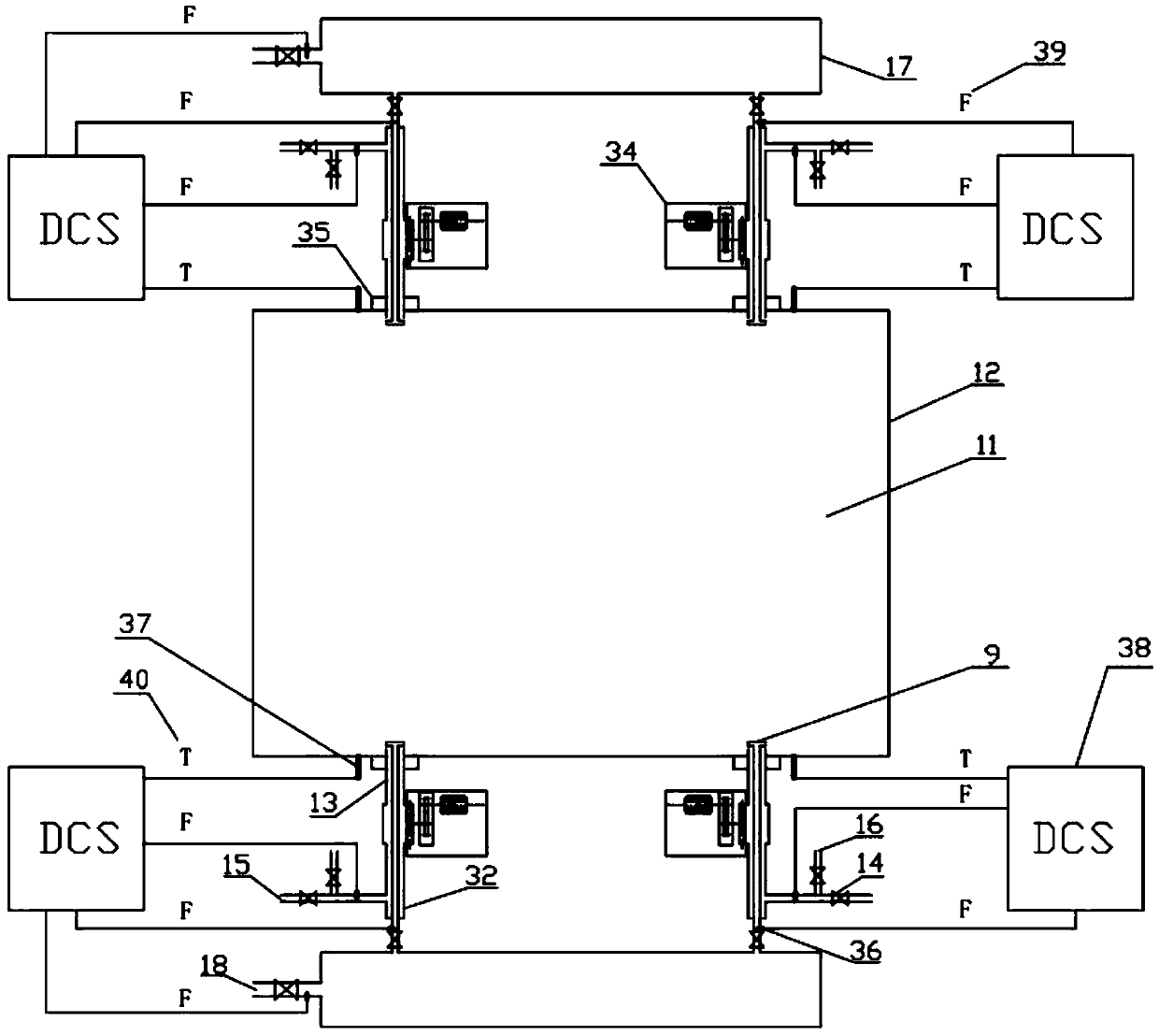

[0021] figure 1 Shown is the structural schematic diagram of the wall-attached air unit device for preventing high-temperature corrosion of the boiler water wall in the patent of the present invention. The unit device is composed of ventilation sleeve 13 , axial adjustment device 34 , sealing device 35 , secondary air nozzle 9 and connection sleeve 32 . The ventilation casing is composed of a central secondary air pipe 6, a compressed air outer pipe 5, a spiral baffle 33, and a zirconia ceramic heat-insulating pipe 10 threaded on the compressed air outer pipe 5. The hole formed by the bending of the water wall tube extends into the furnace; the central secondary air passage 4 is surrounded by the inner wall of the central secondary air pipe 6, and the compressed air passage 3 is formed by the inner wall of the compressed air outer pipe 5 and the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com