Pre-charging device and method of high-voltage frequency converter

A high-voltage inverter and pre-charging technology, which is applied in the direction of circuit devices, battery circuit devices, output power conversion devices, etc., can solve the problems of high cost, insufficient pre-charging, resistance heating, etc., and achieve low cost and no energy loss , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

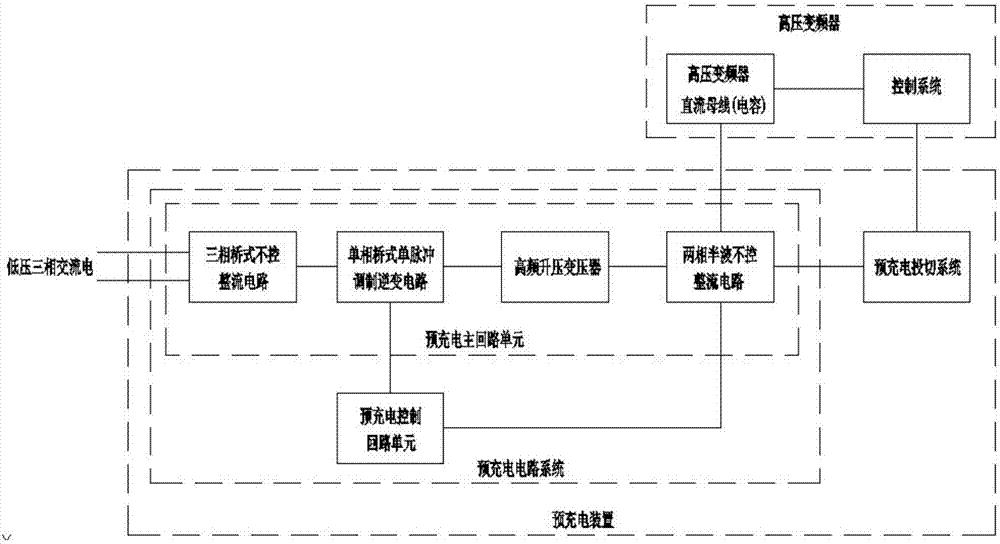

[0033] With reference to Embodiment 1, the pre-charging main circuit unit includes a three-phase bridge type uncontrolled rectification circuit, a unidirectional bridge type single pulse modulation inverter circuit, a high-frequency step-up transformer and a two-phase half-wave uncontrolled rectification circuit;

[0034] The three-phase bridge-type uncontrolled rectification circuit is used to receive the AC voltage output by the low-voltage AC power supply, rectify the received AC voltage to obtain a DC voltage, and output the DC voltage to the unidirectional bridge-type single-pulse modulation inverter circuit;

[0035] The unidirectional bridge-type single-pulse modulation inverter circuit is used to receive a DC voltage, modulate and invert the DC voltage to obtain an AC square wave voltage, and then output the AC square wave voltage to a high-frequency step-up transformer;

[0036] The high-frequency step-up transformer is used to receive the AC square wave voltage, and ste...

Embodiment 3

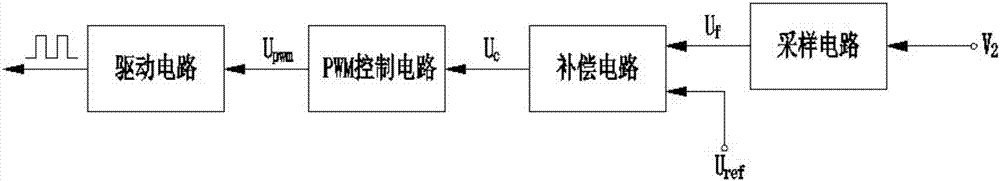

[0040] In combination with Embodiment 1 and Embodiment 2, the pre-charging control loop unit includes a sampling circuit, a compensation circuit, a PWM control circuit, and a driving circuit connected in sequence; the pre-charging control loop unit and the single-phase bridge single pulse modulation The inverter is controlled and connected, and is used to control the turn-on or turn-off of the switching device in the single-phase bridge type single-pulse modulation inverter. Such as image 3 As shown, the pre-charging control loop unit controls the AC square wave output by the single-phase bridge-type single-pulse modulation inverter, so that the AC square wave passes through the high-frequency step-up transformer and the two-phase half-wave does not The amplitude of the DC voltage obtained by controlling the rectifier can be increased from low, and the DC voltage is detected for closed-loop control.

Embodiment 4

[0042] As a preferred solution of the second embodiment, an inductor for filtering is connected in series between the output end of the two-phase half-wave uncontrolled rectification circuit and the DC bus capacitor of the high-voltage inverter.

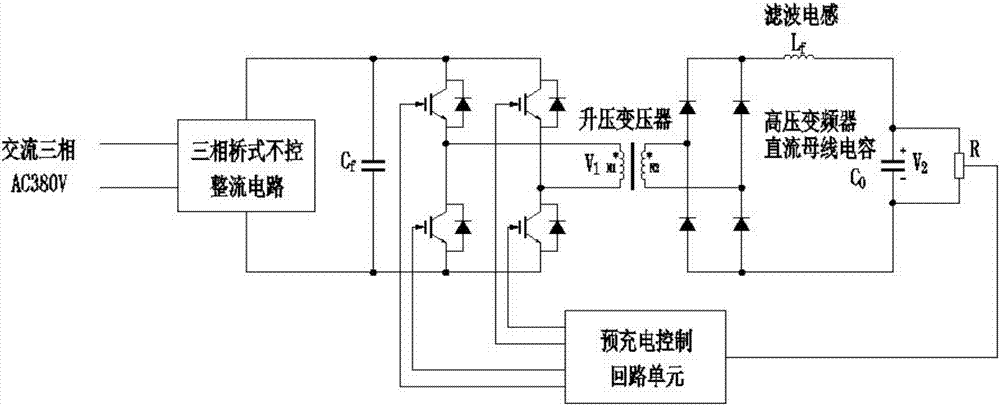

[0043] The high-voltage inverter pre-charging device provided by the present invention first passes the input low-voltage AC power through a three-phase bridge-type uncontrolled rectifier circuit, a single-phase bridge-type single-pulse modulation inverter circuit, a high-frequency step-up transformer, and a two-phase half-wave uncontrolled rectifier circuit, that is, after AC / DC-DC / AC-AC / DC conversion, the final output DC voltage charges the DC bus capacitor of the inverter; secondly, by controlling the four switching devices in the single-phase bridge single-pulse modulation inverter circuit The turn-on, turn-off and turn-on time of the time, so that the DC voltage amplitude increases from low to low with a certain slope. The slope ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap