Loudspeaker sound generation hole plugging processing method and device and terminal equipment

A processing method and terminal equipment technology, applied to speaker screens, chemical instruments and methods, frequency/direction characteristic devices, etc., can solve the problems of speaker sound hole area reduction, deposition, sound mixed with noise, etc., to improve user experience, The effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

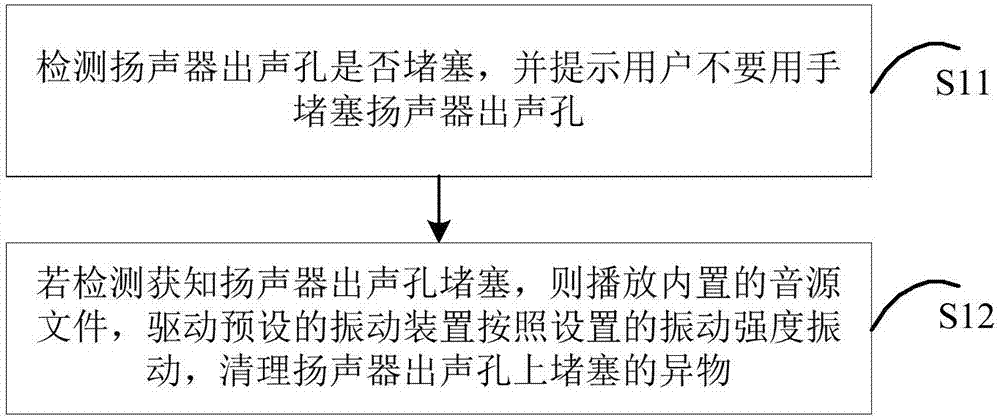

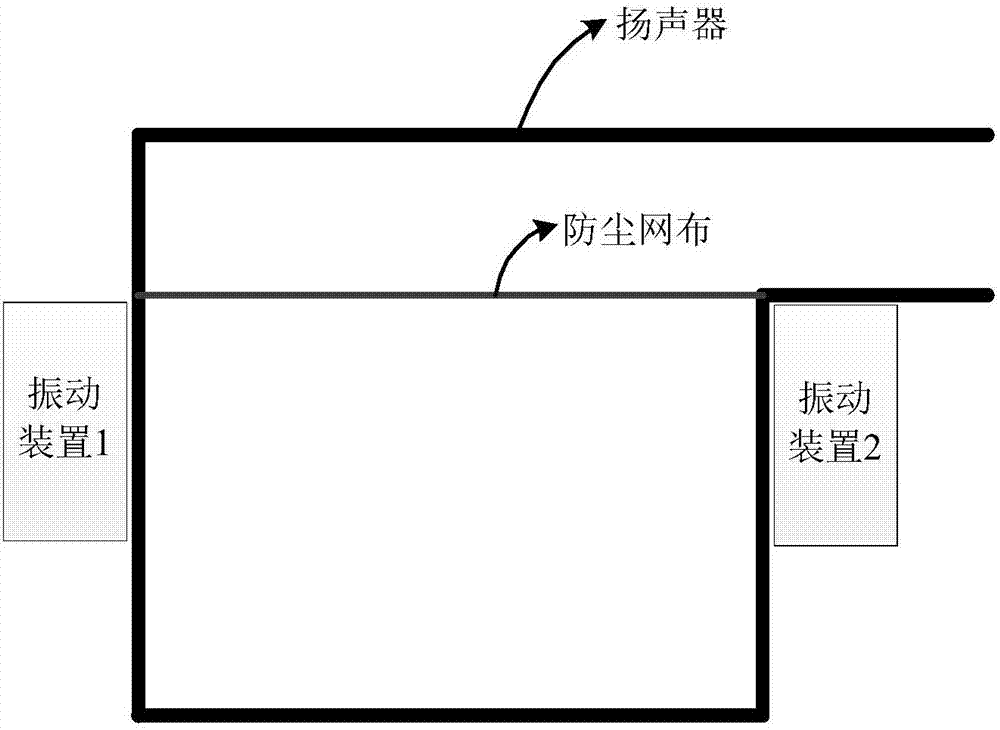

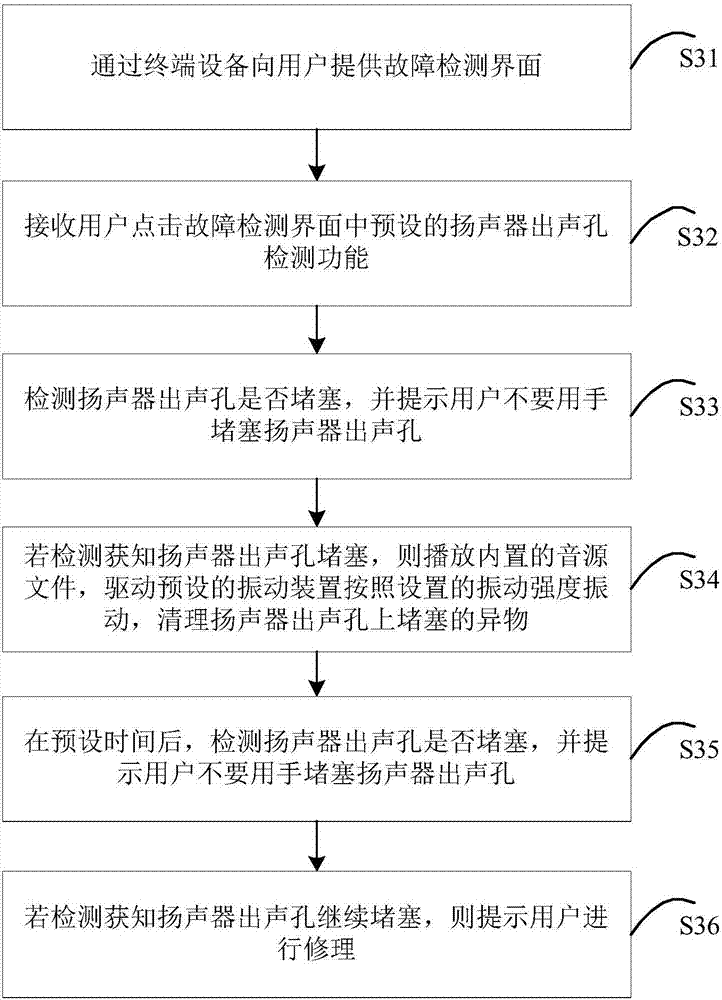

Method used

Image

Examples

example 1

[0047] Example 1: The vibration intensity of the driven vibration device is constant when the built-in audio file is played.

[0048] In this example, the vibration intensity of the vibration device driven when the built-in audio file is played is set to be constant, then when the vibration device is driven by playing the audio file, the vibration intensity of the vibration device will not change during the playback of the audio file. For example, assume that the vibration intensity of the vibration device driven by the built-in sound source file is set to 0.45mm / s when playing. When it is detected that the sound outlet of the speaker of the terminal device is blocked, the vibration device is driven by playing the built-in audio file, and the vibration intensity of the vibration device is always 0.45mm / s during the playback of the audio file.

example 2

[0049] Example 2: When the built-in audio file is played, the vibration intensity of the driven vibration device increases according to the playing time.

[0050] In this example, the vibration intensity of the vibration device driven by the built-in audio file is set to increase according to the playing time. Increments as the playback time progresses.

[0051] For example, assuming that the playback time of the built-in audio file is 60s, set the vibration intensity of the vibration device driven 20s before playback to 0.45mm / s, and set the vibration intensity of the vibration device driven from 21s to 40s to 0.71mm / s s, set the vibration intensity of the vibration device driven during 41s to 60s of playback as the maximum vibration intensity value of the vibration device 1mm / s. When it is detected that the sound hole of the speaker of the terminal device is blocked, by playing the built-in audio file, the preset vibration device is driven to vibrate according to the increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com