Frame corner connecting piece glue dispenser capable of feeding automatically and application method thereof

A corner connector and automatic feeding technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of continuous production and low production efficiency, and achieve improved production efficiency, accurate dispensing, and high economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments.

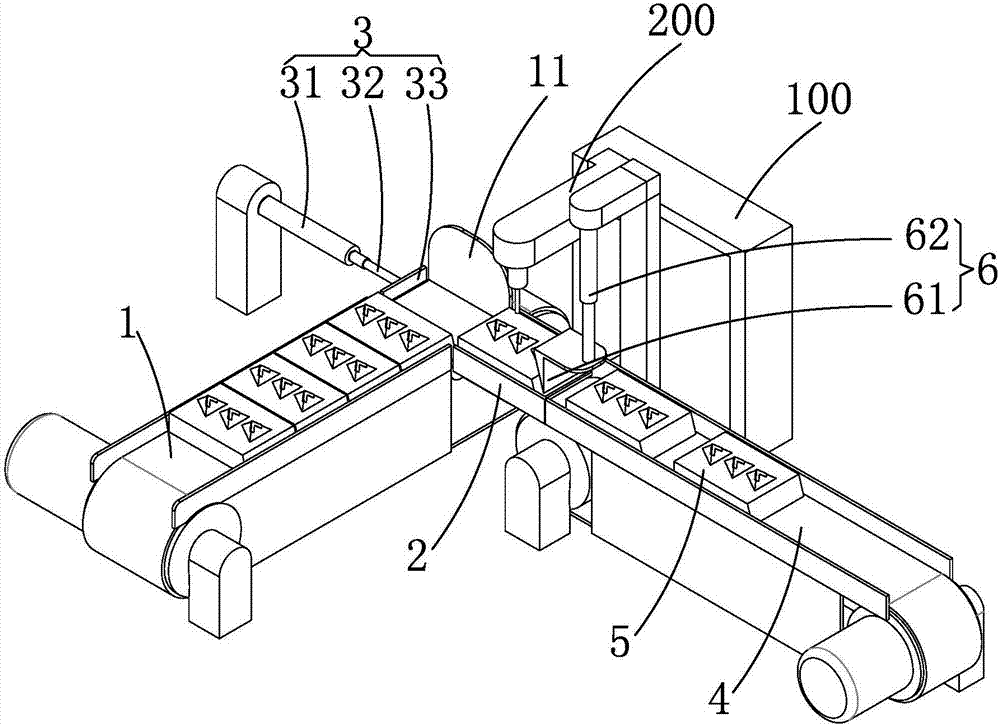

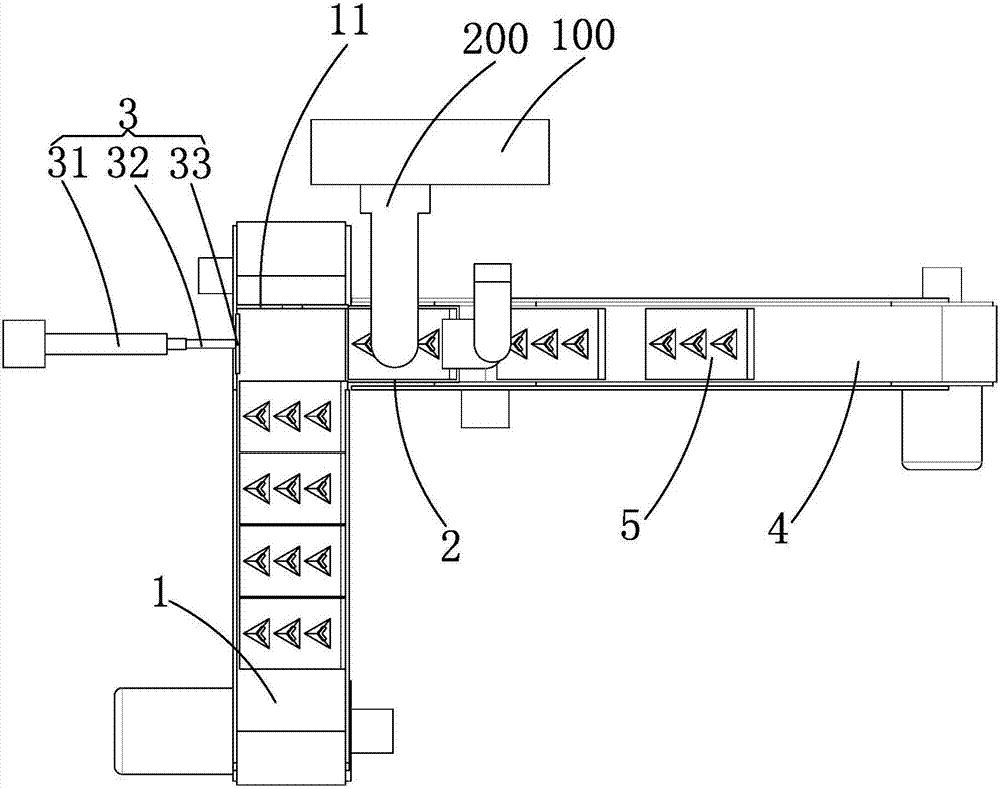

[0022] Such as figure 1 with figure 2 As shown, an automatic feeding frame corner connector dispensing machine according to the present invention includes a frame 100, a dispensing device 200 arranged on the frame 100 and a feeding device arranged below the dispensing device 200 .

[0023] The dispensing device 200 is the same as the common type of dispensing machine on the market. Compressed air is sent into the glue bottle (syringe), and the glue is pressed into the feeding pipe connected to the piston chamber. When the piston is in the upstroke, the piston chamber is filled. Glue, when the piston pushes down the dispensing needle, the glue is pressed out from the nozzle, and the dispenser moves in three axes.

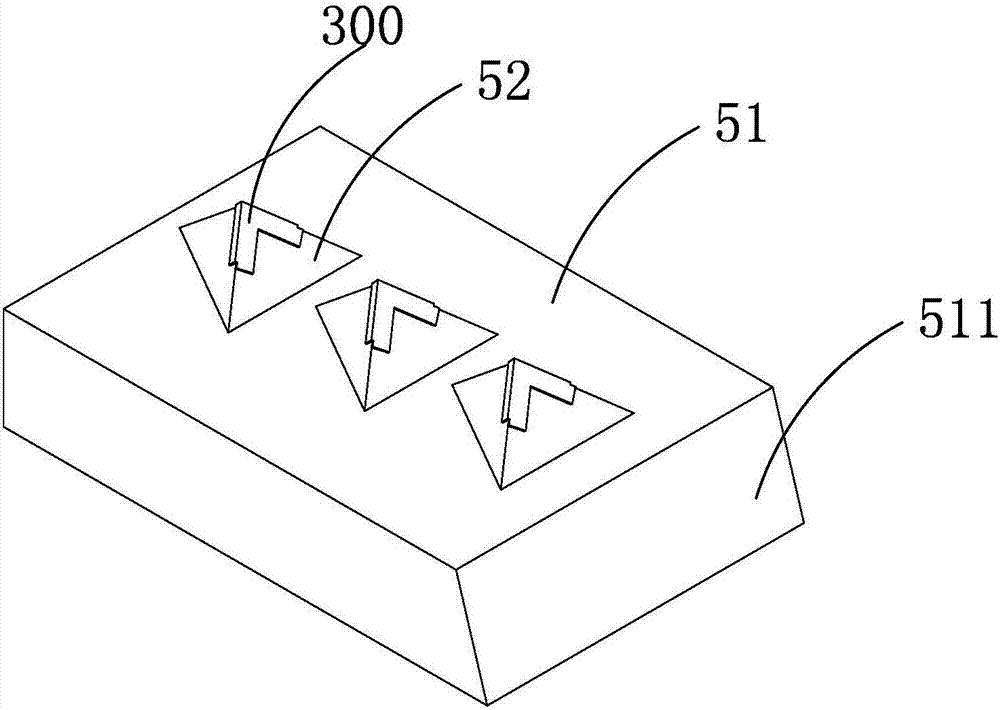

[0024] Such as figure 1 with figure 2 As shown, the feeding device includes a feeding conveyor belt 1, a dispensing table 2, a push mechanism 3, a feeding conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com