Straight walking type plate shearing machine

A straight-line walking and shearing machine technology, which is applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problem that walking splitting shears cannot maintain straight-line walking, so as to prevent left and right shaking and reduce The effect of resistance and force uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

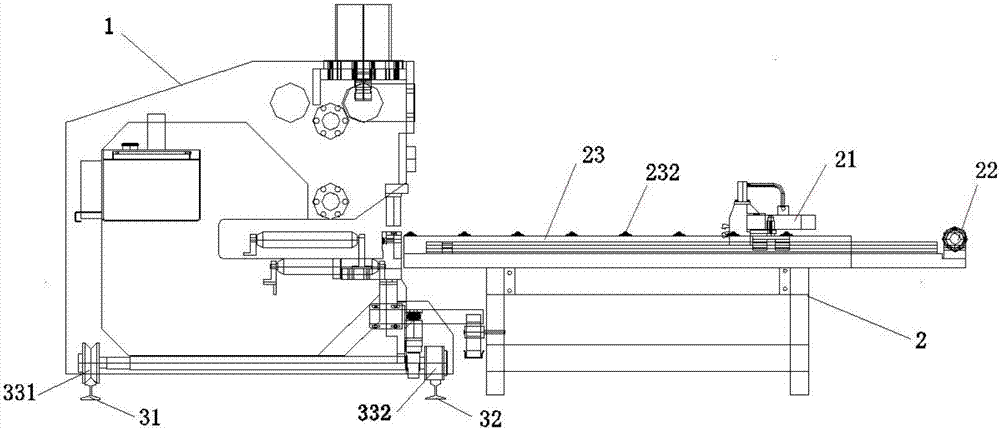

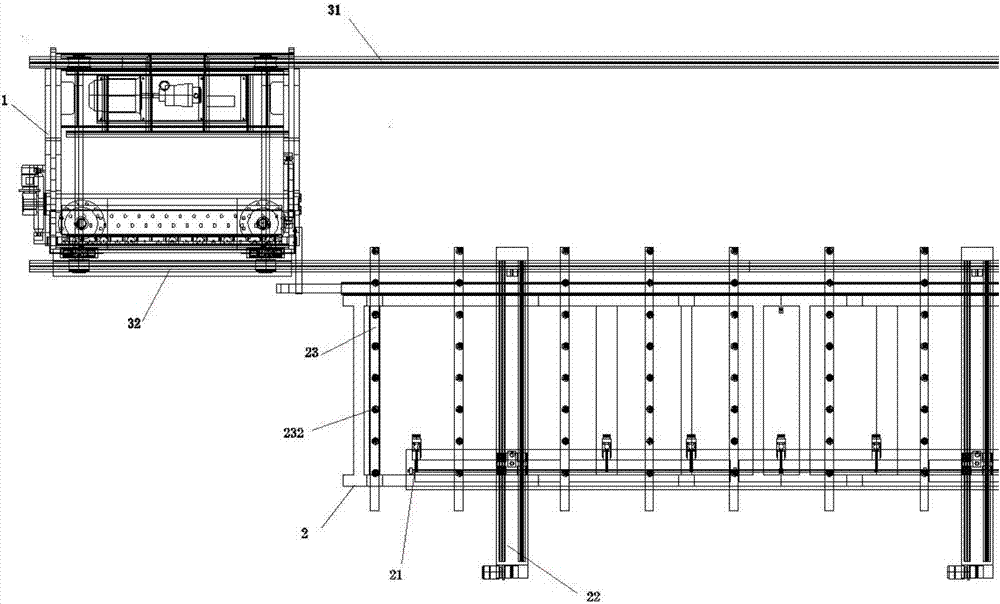

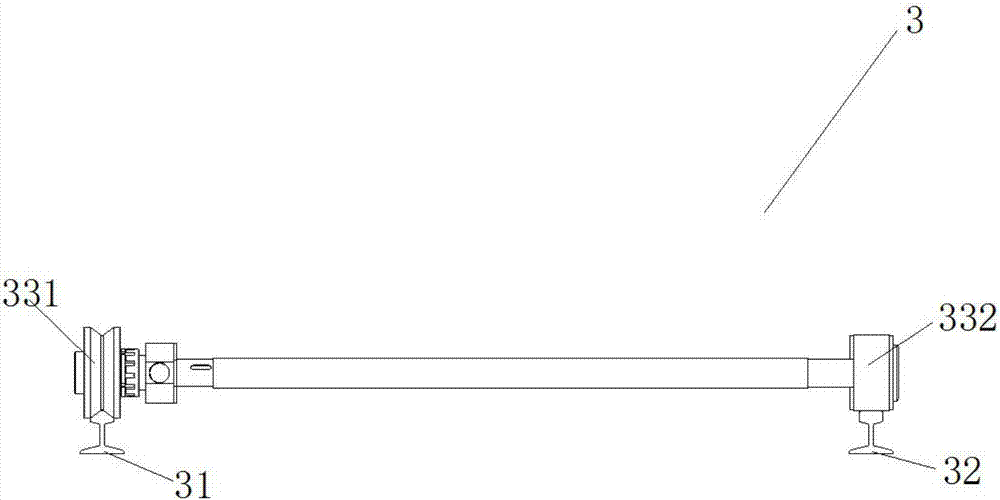

[0044] Such as Figure 1~6 , The embodiment 1 of the present invention provides a linear walking type sheet metal shearing machine, including a splitter 1 and a feeding device 2. The bottom of the splitter 1 is provided with a linear walking mechanism 3, and the linear walking mechanism includes a tip rail 31, a flat Rail 32 and multiple sets of roller assemblies, the upper two sides of the tip rail 31 are double inclined planes, the distance between the top ends of the double inclined planes is less than the distance between the bottom ends of the double inclined planes, the center lines of the flat rail 32 and the tip rail 31 are parallel to each other to form a walking track, the roller assembly 33 includes a concave roller 331 and a parallel roller 332. The groove of the concave roller 331 is provided with a groove that fits with the upper part of the tip rail 31. The concave roller 331 and the parallel roller are arranged on the same axle 331. The double inclined surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com