Automobile bumper injection molding process system integration

A technology of automobile bumper and process system, which is applied in the field of automobile bumper injection molding process system integration, can solve the problems of high cost, consumption, multi-manpower and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

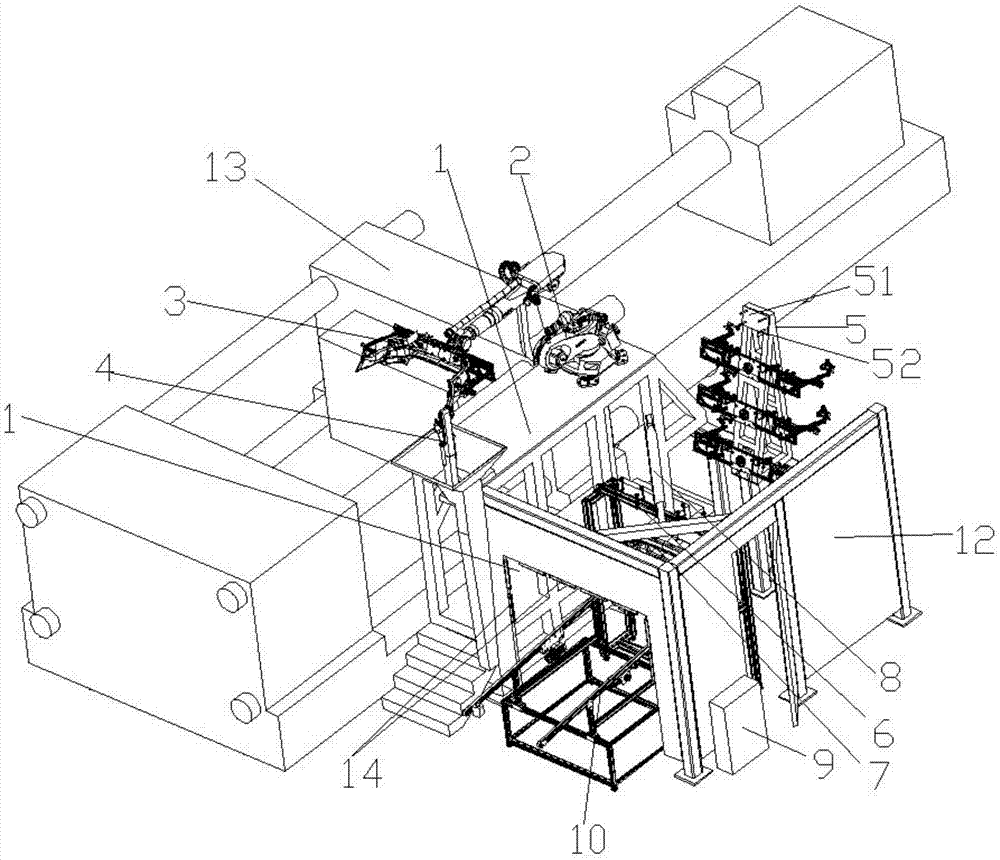

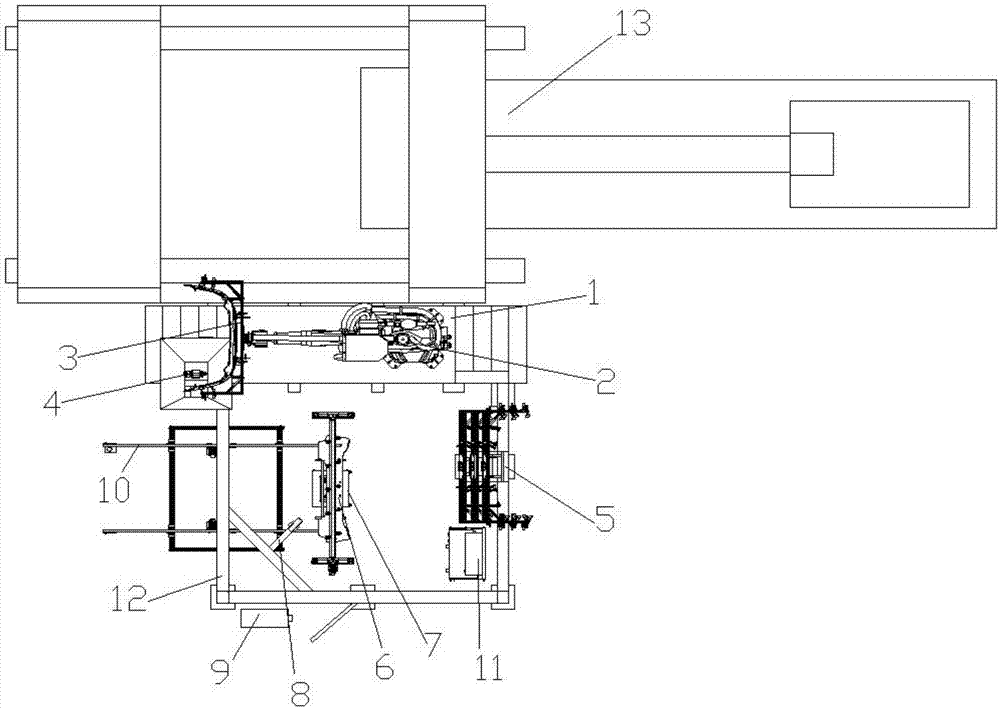

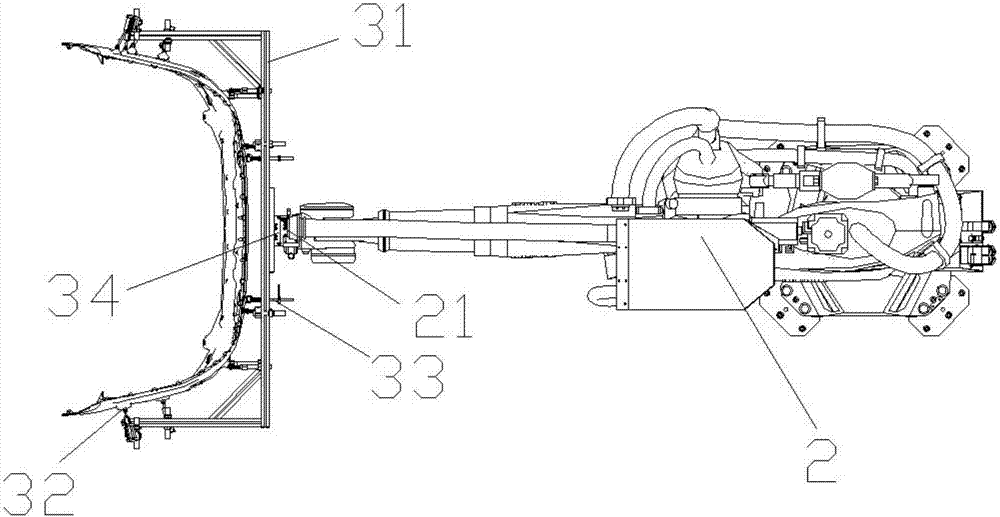

[0036] Embodiment: An automobile bumper injection molding process system integration, including a base 1, a material retrieving robot 2, a material retrieving gripper 3, a material head shearing device 4, a gripper placement frame 5, a product turning mechanism 6, and a weighing mechanism 7 , Flame processing device 8, flame control box 9, blanking assembly line 10, electric control box 11 and guardrail 12;

[0037] The base is placed on one side of the injection molding machine 13, the material retrieving robot is fixed on the upper end surface of the base and is located at the product outlet of the injection molding machine, and the material retrieving gripper is detachably installed on the retrieving machine. on the robot;

[0038] The material head shearing device is fixed at one end of the base and is located on the side of the base away from the reclaiming robot;

[0039] The guardrail is placed close to the base, and the guardrail is located on the side of the base awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com