Self-demoulding type injection moulding structure

A model, self-release technology, applied in the field of auto parts processing, can solve problems such as failure to release the mold smoothly, parts breakage, etc., to achieve the effect of improving cooling efficiency and large temperature conduction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

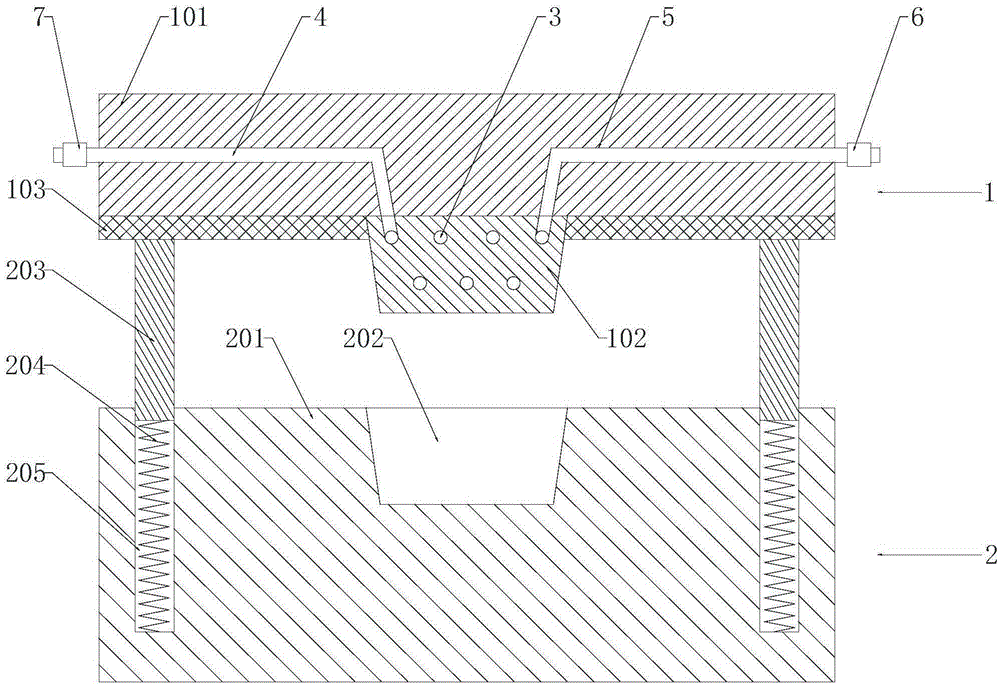

[0023] Such as figure 1 As shown, the injection molding structure of the self-release model includes an upper mold 1 and a lower mold 2 corresponding to the upper mold 1; The upper mold core 102 on the lower surface and through the push plate 103, the upper mold plate 101 is provided with a blind hole 104 in the end surface close to the push plate 103, and the blind hole 104 is provided with a first spring 105 acting on the push plate 103;

[0024] The lower mold 2 includes a lower template 201 and a guide column 203, the lower template 201 is provided with a molding cavity 202 corresponding to the upper mold core 102 and a guide hole 205, the guide hole 205 is provided with a second spring 204 connected to the guide column 203, Under the action of the second spring 204, the guide post 203 supports the push plate 103, and the inner wall of the guide hole 205 is provided with a positioning chute 206, and the outer wall of the guide post 203 is provided with a positioning protru...

Embodiment 2

[0028] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the cooling section 3 is spiral. The cooling section 3 has a spiral shape, so that the temperature conduction area is larger and the cooling efficiency is improved.

Embodiment 3

[0030] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes an electromagnetic shut-off valve A6 arranged on the water outlet section 5; the electromagnetic shut-off valve A6 is closed when the mold is closed and opened when the mold is opened. Close the electromagnetic shut-off valve A6 during mold closing, so that the cooling water in the cooling section 3 stops flowing, and the high-temperature plastic in the molding cavity 202 will not be cooled during mold closing, so as to avoid affecting the molding of plastic products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com