A high release polyurethane adhesive

A polyurethane adhesive, high peeling technology, used in polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of reduced peel strength and insufficient bonding fastness , to achieve the effect of improving the bond strength

Active Publication Date: 2020-06-30

JIANGSU HUADA NEW MATERIAL CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But what follows is that the bonding fastness is not enough, and the peel strength is greatly reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5、 comparative example 1-2

[0020] The content of each component of polyurethane adhesive in embodiment 1-5 and comparative example 1-2 is as shown in table 1, does not contain epoxy resin in comparative example 1, then is the self-made polyester polyol that adopts in comparative example 2 c Excessive.

[0021] Each component content table of polyurethane adhesive in table 1 embodiment 1-5 and comparative example 1-2

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Login to View More

Abstract

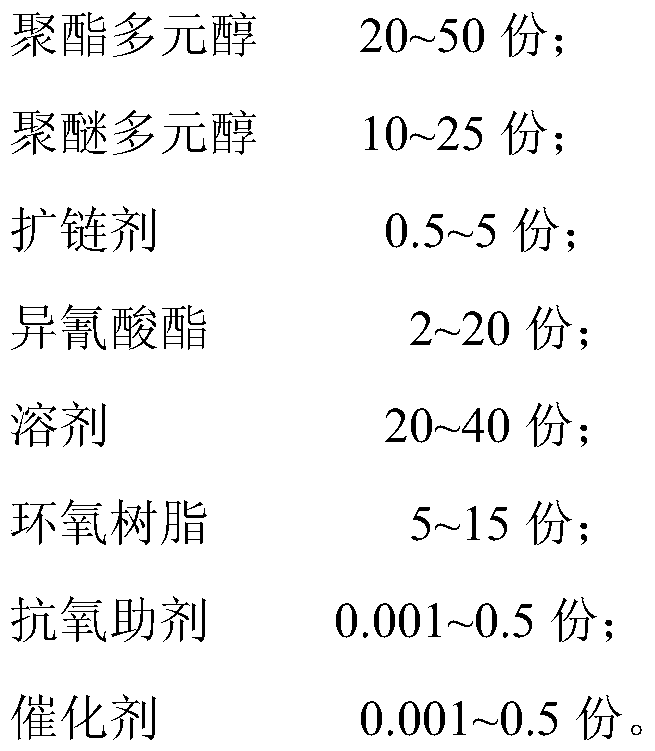

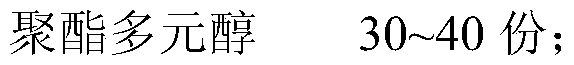

The invention relates to a highly-stripped type polyurethane adhesive. The highly-stripped type polyurethane adhesive is prepared from the following components in parts by weight: 20 to 50 parts of polyester polyol, 10 to 25 parts of polyether polyol, 0.5 to 5 parts of chain extender, 2 to 20 parts of isocyanate, 20 to 40 parts of solvent, 5 to 15 parts of epoxy resin, 0.001 to 0.5 part of anti-oxidizing additive and 0.001 to 0.5 part of catalyst. The highly-stripped type polyurethane adhesive has the advantages that by using the particular content of polyester polyol, polyether polyol and isocyanate to react, and adding a certain amount of the epoxy resin, the adhering strength is improved; under the condition of the same adhering force, the usage amount of glue is reduced, and the loss of stripping strength is avoided.

Description

technical field [0001] The invention relates to an adhesive, in particular to a high-peeling polyurethane adhesive. Background technique [0002] Polyurethane adhesives refer to adhesives that contain urethane groups or isocyanate groups in the molecular chain. Polyurethane adhesives are divided into two categories: polyisocyanate and polyurethane. Polyurethane adhesive is an important part of the rapidly developing polyurethane resin. It has excellent shear strength, impact resistance and flexibility, as well as excellent rubber properties. It can adapt to the adhesion of different thermal expansion coefficient substrates. It forms a soft-hard transition layer between the substrates, which not only has strong adhesion, but also has excellent cushioning and shock absorption functions, so it is suitable for cloth composites. Solvent-based two-component polyurethane adhesives are widely used in the lamination of cloth to cloth and cloth to film. However, with the recent sha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J175/08C09J11/06C08G18/48C08G18/42C08G18/58C08G18/32C08G18/66C08G18/65

CPCC08G18/3206C08G18/4018C08G18/4241C08G18/4854C08G18/6511C08G18/6607C08K5/1345C09J11/06C09J175/08

Inventor 訾少宝邹晓菲张魁吕少波李吉成刘少勇

Owner JIANGSU HUADA NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com