A kind of prefabricated pile construction method

A construction method and prefabricated pile technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low bearing capacity, inability to realize the centrifugal molding of reinforced concrete with strong tensile strength, and low density of concrete prefabricated piles , to achieve the effects of prolonging the service life, facilitating support and positioning, and enhancing the compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

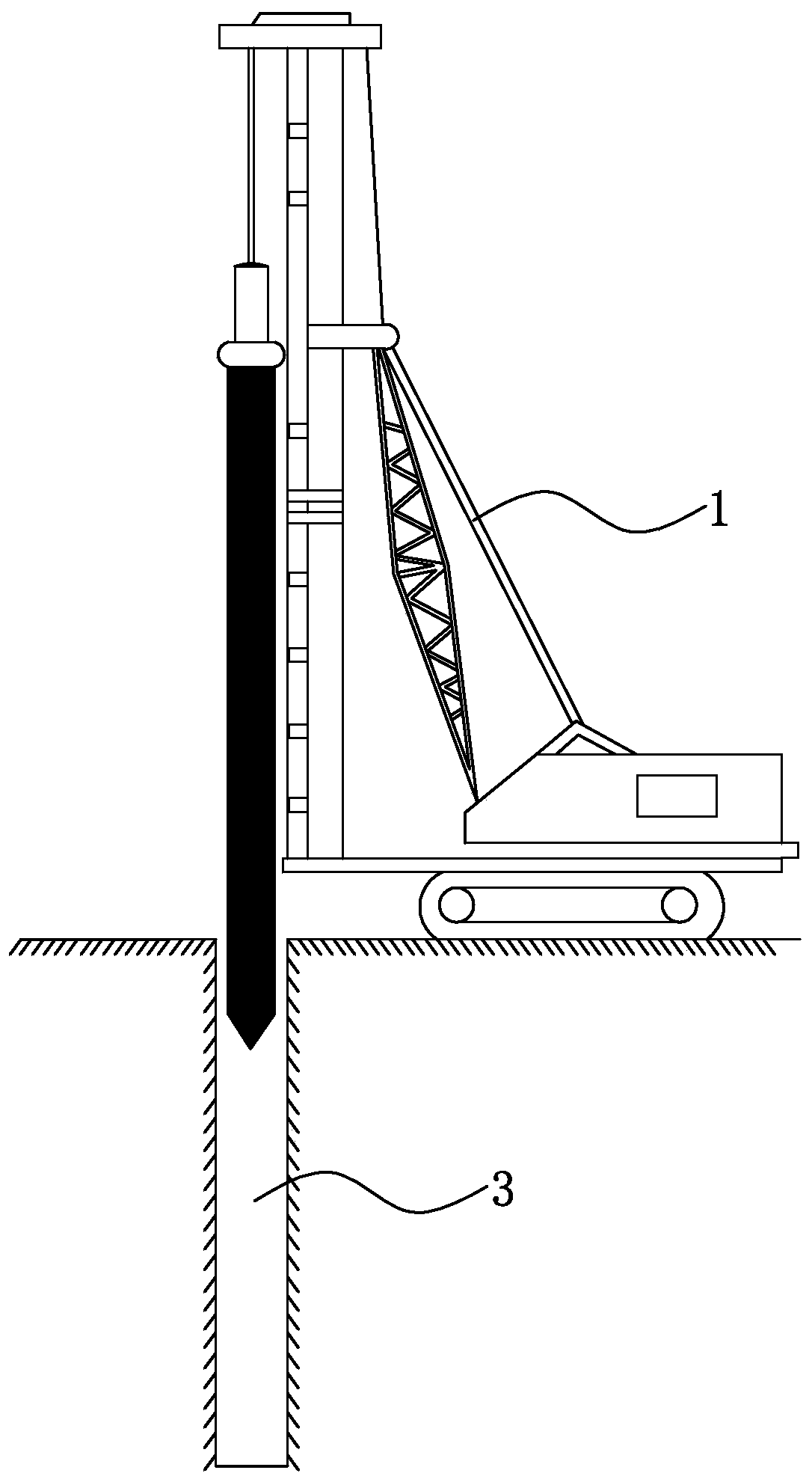

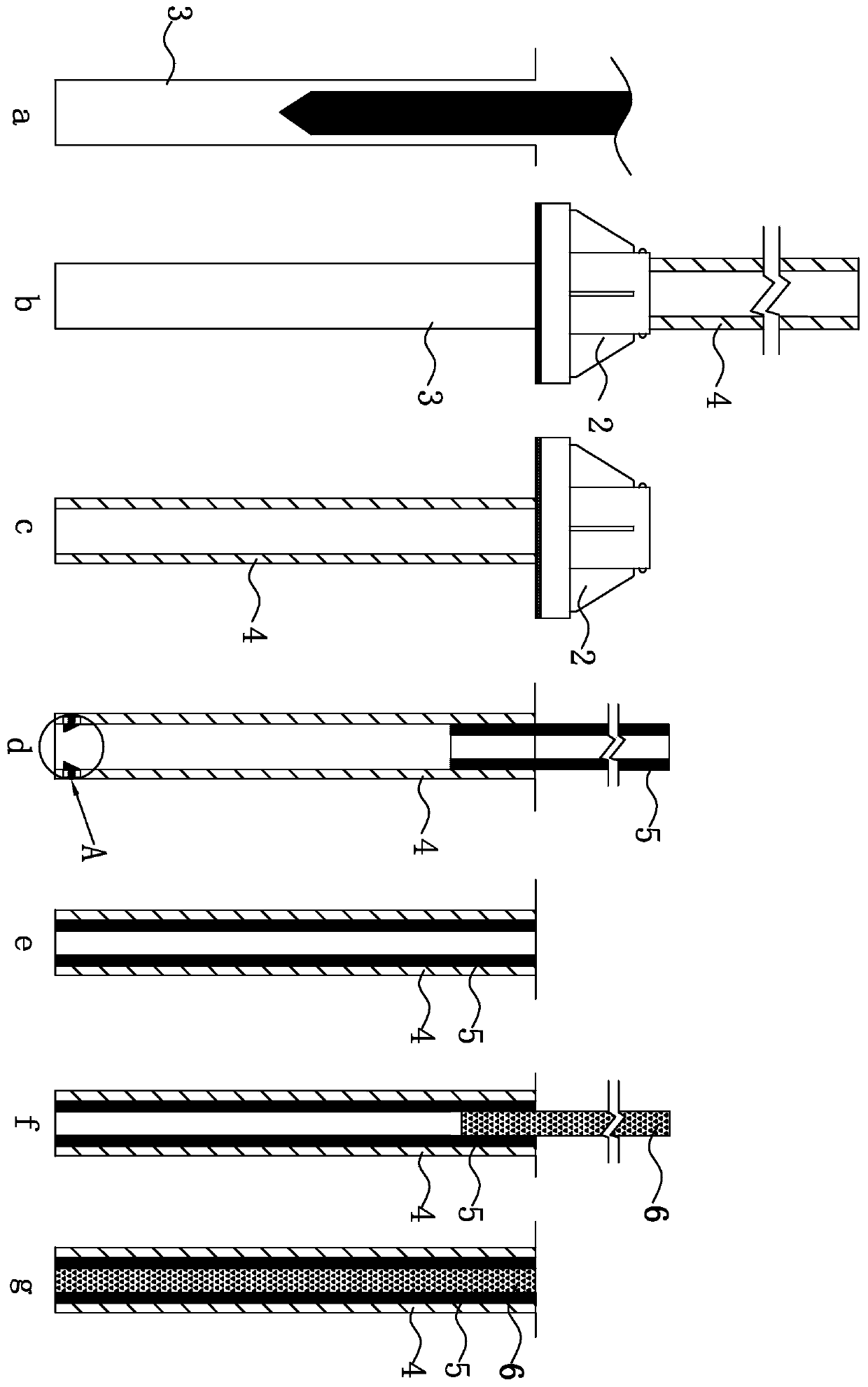

[0055] Embodiment one: a kind of prefabricated pile construction method, with reference to figure 1 and figure 2 , including the following steps:

[0056] Step 1: Determine the pile position, measure and stake out the foundation pit, and determine the excavation depth and aperture of the foundation pit of the prefabricated pile 4 according to the geological conditions revealed by the design drawings of the prefabricated pile 4 and the engineering geological report. The central coordinates define the 4 central points of the prefabricated piles;

[0057] Step 2: Manufacture the prefabricated hole 3, according to the design elevation and aperture of the prefabricated pile 4, use the pile driver 1 to drill down along the center point on the foundation;

[0058]Step 3: Clean up the prefabricated hole 3, crush the rock block with a pneumatic rock drilling machine, and suck it out with a suction dredge after crushing until it reaches the design elevation;

[0059] Step 4: After t...

Embodiment 2

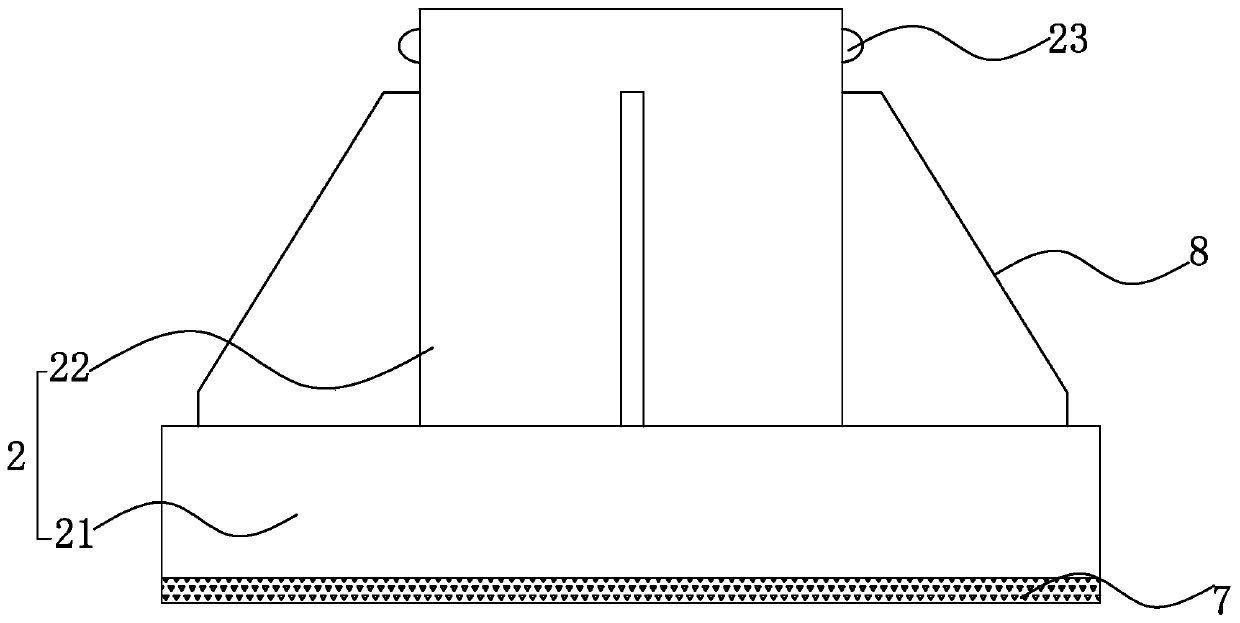

[0067] Embodiment 2: An auxiliary support for prefabricated pile construction, placed above the prefabricated hole 3 during construction, for supporting and positioning the prefabricated pile 4, refer to image 3 , comprising a base 21, the lower surface of the base 21 is provided with a shock absorber 7, and the shock absorber 7 is composed of rubber pads and cotton pads; the base 21 is provided with a sleeve 22, and the top of the base 21 is welded together with the bottom of the sleeve 22 ; The upper ring of the outer wall of the sleeve 22 is provided with a number of braces 8; the base 21 and the sleeve 22 are made of steel.

[0068] refer to Figure 4 , the sleeve 22 is hollow, the center of the base 21 is provided with a through hole communicating with the sleeve 22, the fastener 23 is circumferentially arranged along the inner wall of the sleeve 22, and the inner wall of the sleeve 22 is provided with a plurality of first grooves 24, The bottom of the first groove 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com