Model for simulating overload hysteresis effect in fatigue crack propagation

A technology of fatigue crack growth and hysteresis effect, applied in the field of fatigue crack growth life model, it can solve problems such as large error, small overload influence area, and failure to reflect delay and hysteresis phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

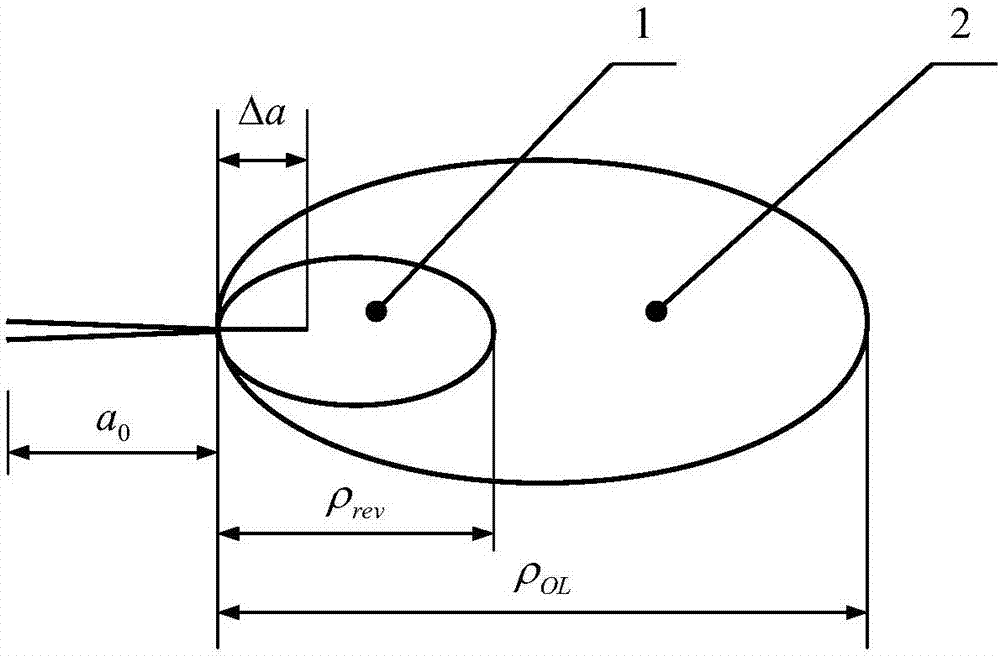

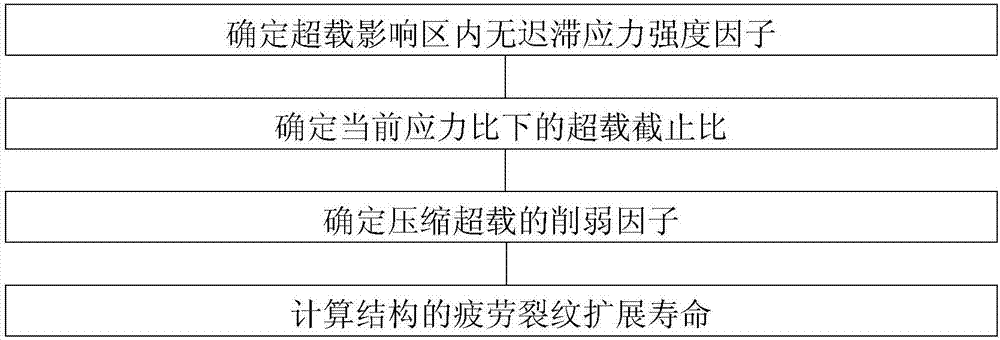

[0040] This embodiment is a model for simulating the overload hysteresis effect in fatigue crack growth.

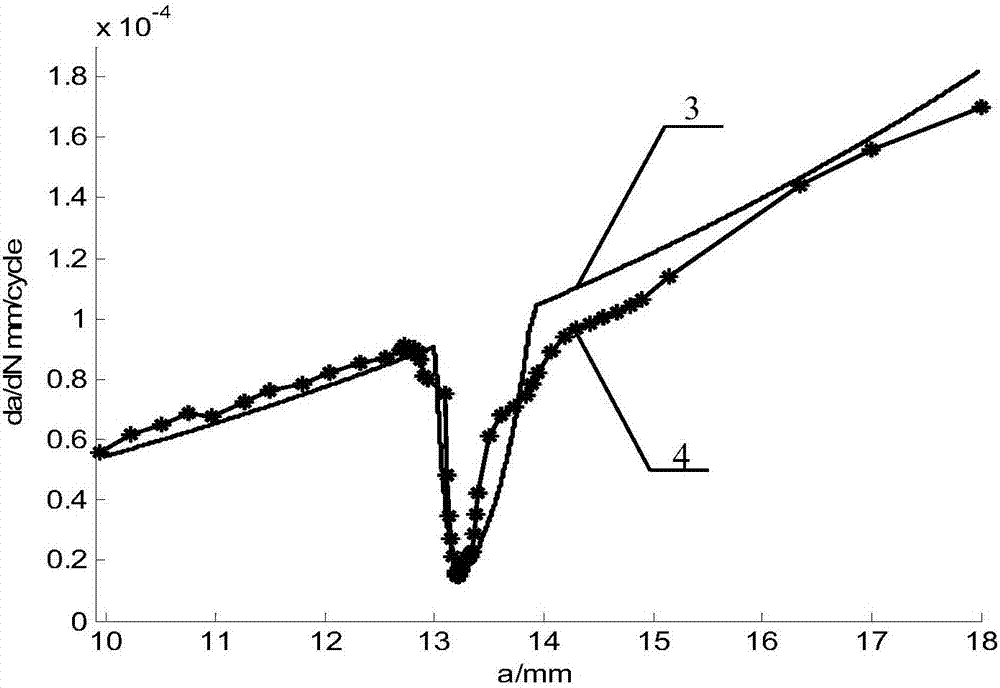

[0041] The test piece in this embodiment is 2A12-T4 aluminum alloy M (T) test piece, the test piece width W=100mm, the test piece thickness B=3.74mm, the material yield strength σ s =336MPa, overload cut-off ratio γ S0 =2.62. Material constant in Walker's formula: C=3.8026×10 -11 , p=3.4145, q=0.6586, t=0.1057. Stress Intensity Factor Threshold ΔK th =2.73(1-R) 0.46 . The specimen is subjected to constant amplitude fatigue load, the initial crack length a i =8mm, when the crack length a=13mm, apply overload, then continue to apply constant amplitude fatigue load, terminate the crack length a f = 30mm. Calculate the fatigue crack growth life for the following four types of loading cases.

[0042] (1) Peak value of fatigue load P max =18kN, stress ratio R=0.06, tensile overload ratio γ OL =1.8,2.2;

[0043] (2) Peak value of fatigue load P max = 20kN, stress rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com