Battery pack structure

A technology of battery packs and batteries, which is applied in the direction of secondary batteries, structural parts, battery pack components, etc., can solve the problems of cumbersome battery pack assembly process, waste of manpower and material resources, poor safety and reliability, and achieve no need for module design and Assembly process, saving time and cost, ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

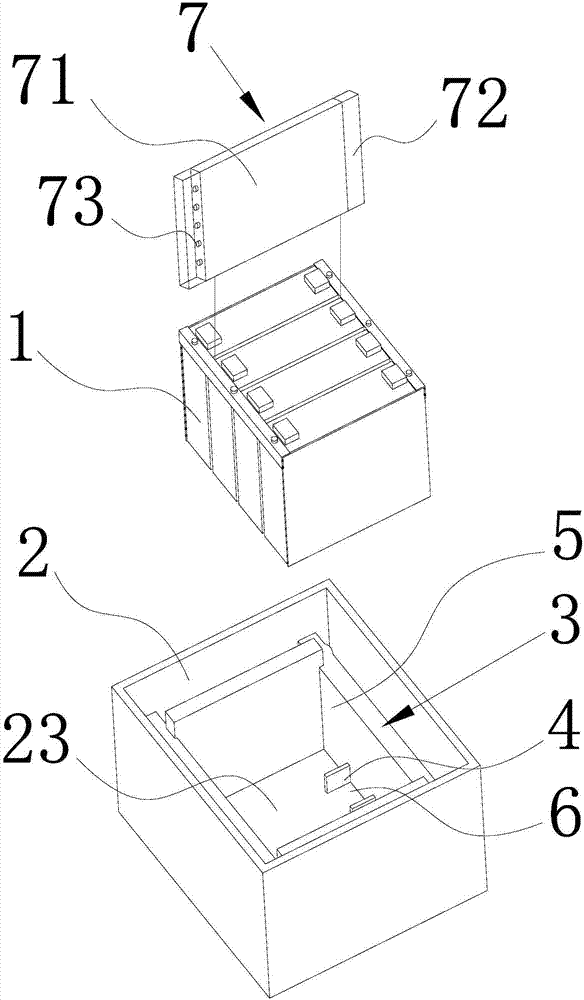

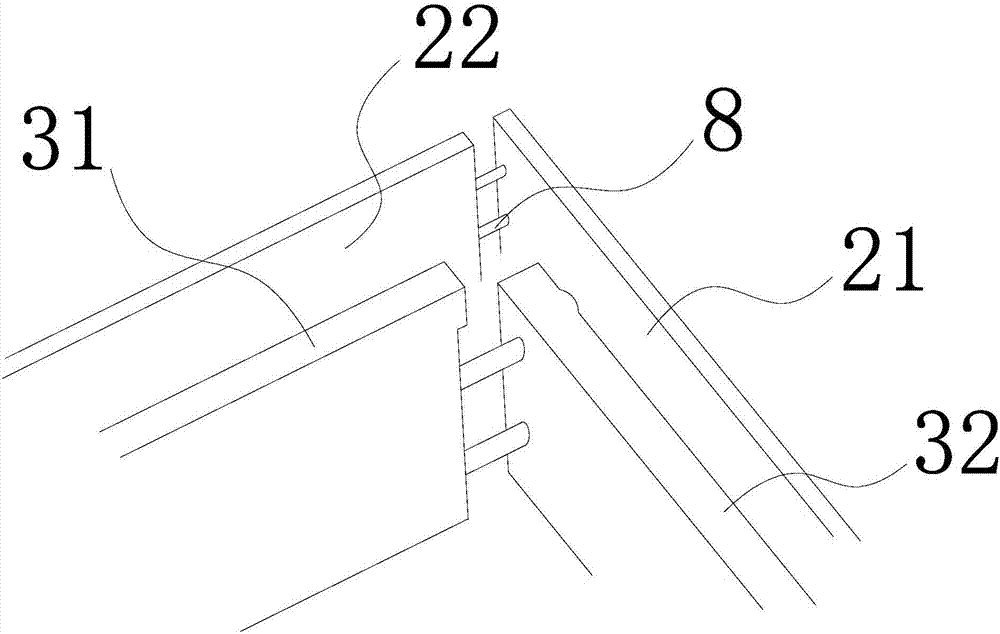

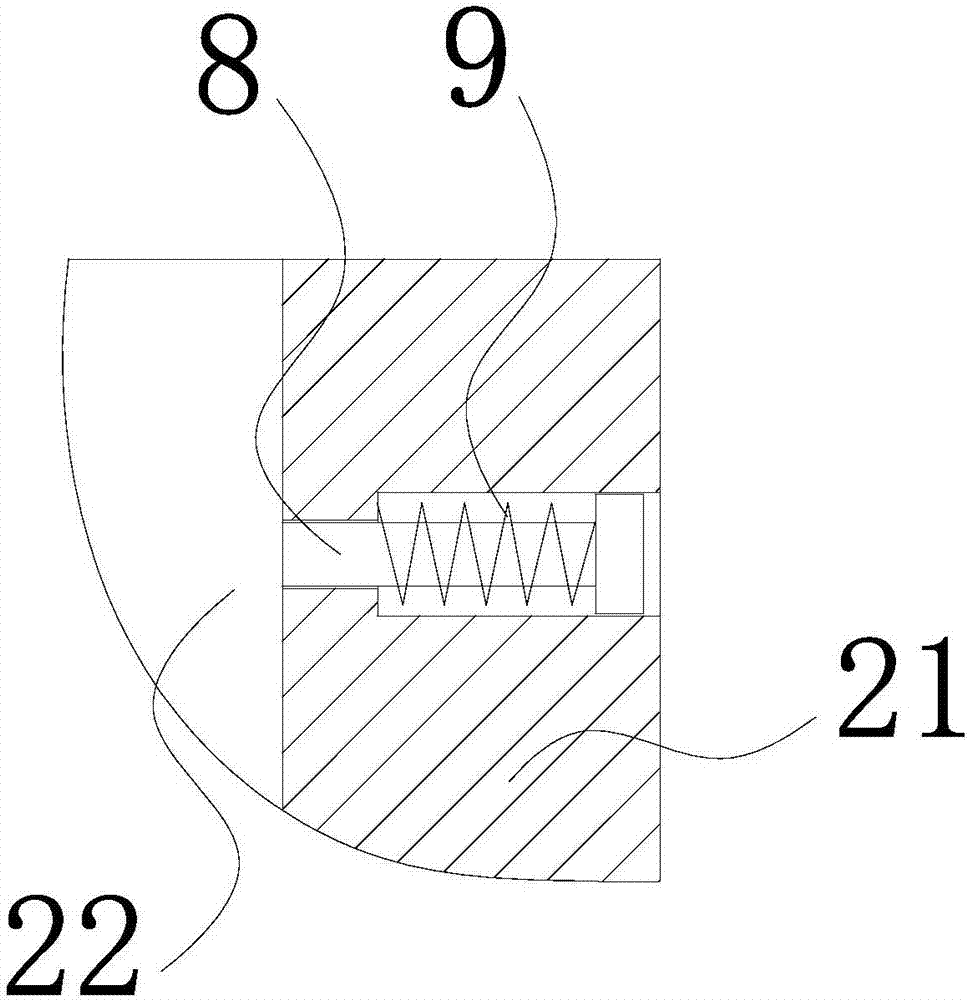

[0025] Such as figure 1 As shown, a battery pack structure of the present invention includes a rectangular box 2 for placing the battery cell 1, and the inner ring surface of the box 2 corresponding to the outer ring surface of the battery core 1 respectively extends inwardly to form an integrated battery The core fixing plate 3, the box body 2 includes the box side panel 21, the box end panel 22, the box bottom plate 23 and the box top plate, the cell fixing plate 3 includes the cell end surface fixing plates corresponding to the end faces on both sides of the cell 1 31. The cell side fixing plates 32 corresponding to the front and rear sides of the cell 1, and the box bottom plate 23 corresponding to the bottom surface of the cell 1 extends inwardly to form a number of limit bosses 4, and the limit bosses 4 extend along the line The arrangement directions of the cores 1 are distributed at equal distances. The cell fixing plate 3 and the limiting boss 4 jointly form a cell modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com