A wooden board bonding machine for building decoration

A bonding machine and wood board technology, which is applied to the jointing of wooden veneers, lamination devices, wood processing appliances, etc., can solve the problems of increasing workload, time-consuming and laborious, etc., to ensure safety, reduce manufacturing costs, and structure solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

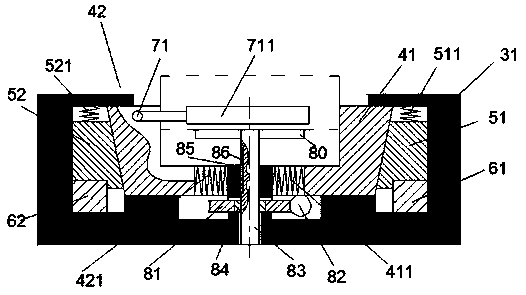

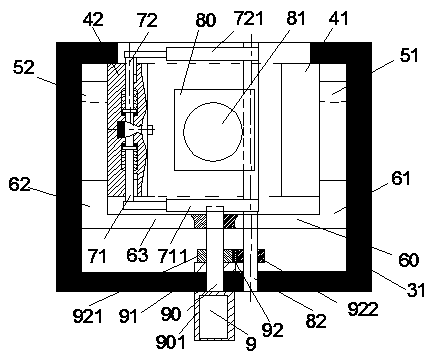

[0014] Combined in front Figure 1-4 The present invention will be described in detail.

[0015] A kind of wood board bonding machine for building decoration according to an embodiment, comprising a calibration device 3, characterized in that: the calibration device 3 comprises a body 31, and the center of the body 31 is provided with two parts that can approach and distance from each other in the left and right directions. A pressing part: a left pressing part 42 and a right pressing part 41, between the lower right extension of the left pressing part 42 and the body 31, the lower left extension of the right pressing part 41 and the lower left extension of the right pressing part 41 A left elastic member 421 and a right elastic member 411 are respectively arranged between the body 31, and a left top that can slide up and down is respectively arranged on the left side of the left pressing member 42 and the right side of the right pressing member 41. Pressing block 52 and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com