Rotary spraying tank body

A technology of rotary spraying and tank body, applied in packaging sterilization and other directions, can solve the problems of unfavorable water resources and heat energy saving, food cannot be sprayed, and the spraying is not uniform enough, so as to ensure the service life and facilitate installation, maintenance and replacement. and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

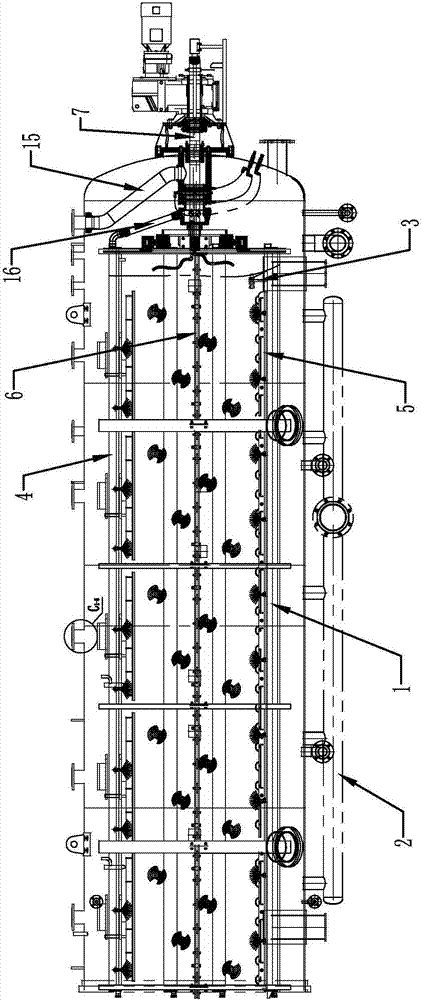

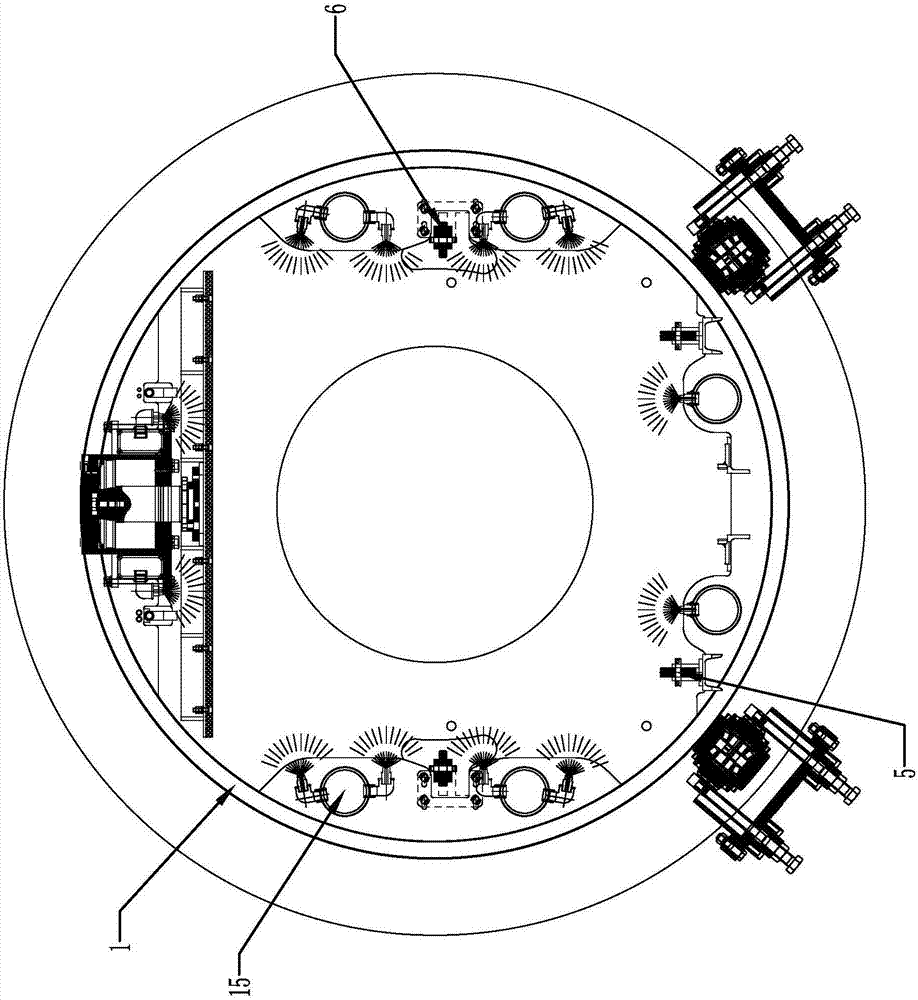

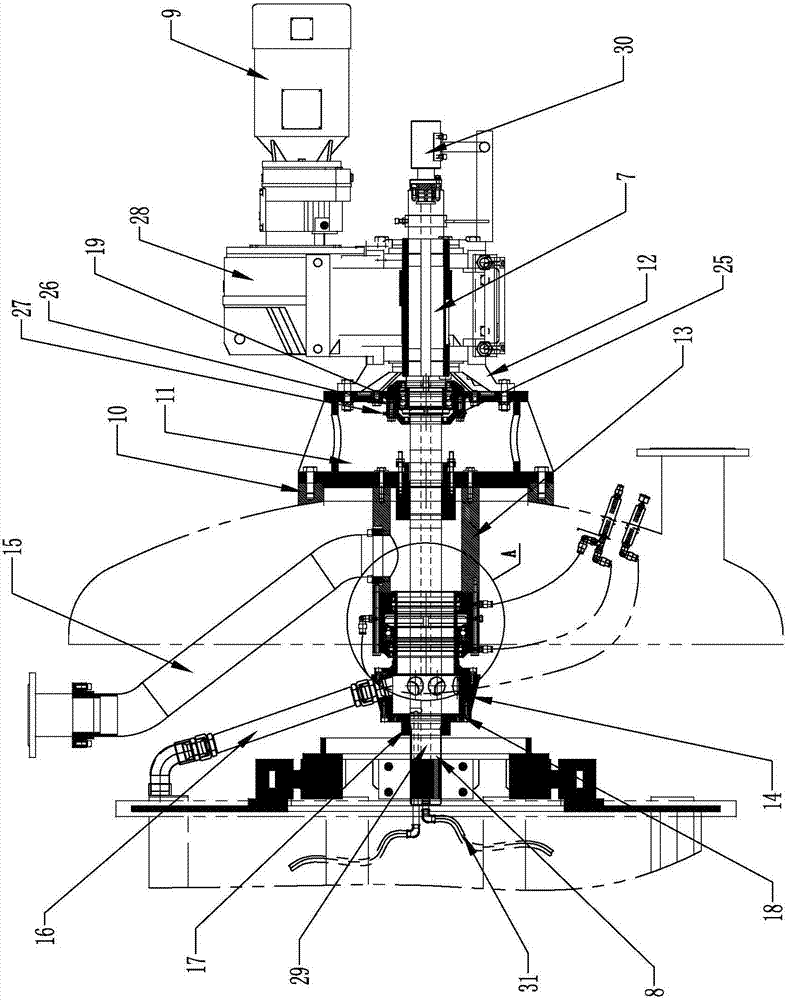

[0025] Such as Figure 1-4 As shown, the rotating spraying tank includes a cage body 1 and a transmission assembly. An intake and exhaust pipe 2 is arranged on the inner side wall of the tank outside the cage body 1. The cage body 1 is installed inside the tank body. The cage body 1 One end of the inside is also provided with a cage rear limit rod 3 for positioning the cage basket pushed into the cage body 1. The four sides of the cage body 1 are respectively provided with water spray pipes 4 with nozzles, and the bottom of the cage body 1 is provided with Two rows of guide rails 5 with pulleys, a row of guide pulleys 6 are respectively arranged on both sides of the cage body 1, the transmission assembly is arranged at one end of the tank body, and the drive shaft 7 of the transmission assembly is inserted into the cage body 1 In the cross coupling 8 at one end, the transmission assembly also includes a drive motor 9 that drives the transmission main shaft 7 to rotate, the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com