Thermoelectricity decoupling transformation and operation method based on heat source end and heat network comprehensive adjustment

An operation method and comprehensive adjustment technology, applied in heating mode, combined combustion mitigation, and central heating, can solve the problems of loss of heat storage, high cost, change in steam turbine thrust, etc., and achieve the effect of increasing heating capacity and reducing the amount of modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

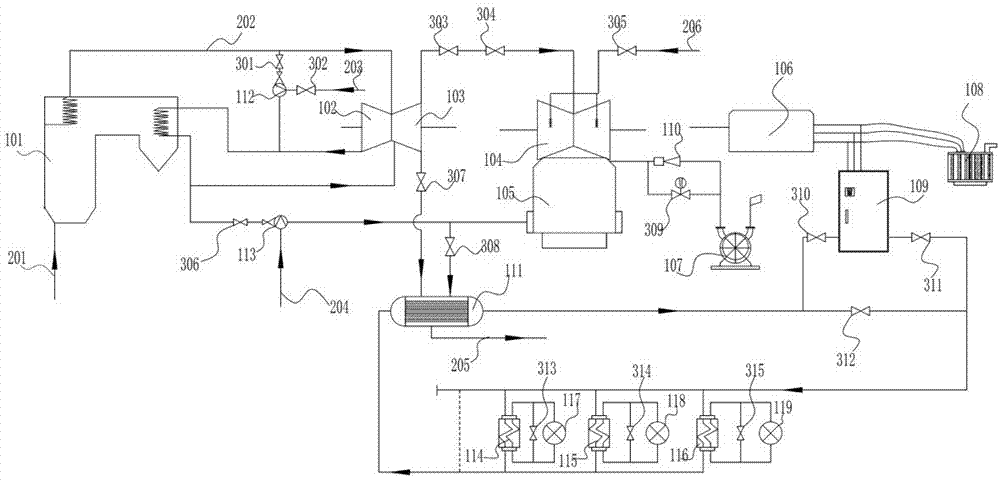

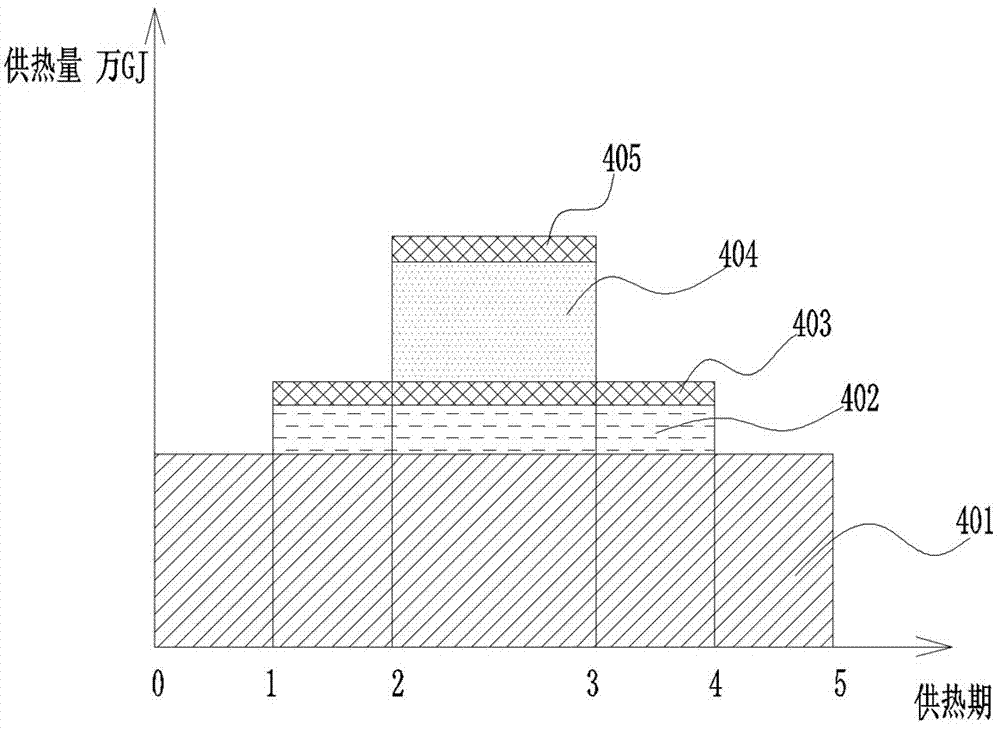

[0041] Reference attached Figure 1-2 , the present invention provides a whole-system thermoelectric decoupling technology based on the comprehensive regulation of the heat source end and the heat network. The steam inlet isolation valve, the injection desuperheating device in the low-pressure cylinder, and the low-pressure cylinder after the pre-vacuumizing device can be detached to increase the heat supply capacity of the unit. Compared with other body transformation technologies, the amount of body modification is less, safe and reliable, and relatively expensive lower. 2. In terms of heat storage, this technical solution is adjusted through the joint adjustment of the first station of the heating network and the second station of the heating network. The first station of the heating network is generally composed of a heating network heater (111), a circulating water pump of the primary heating network, and corresponding valves and pipelines. It is installed on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com