Milk powder brewing and mixing cabin and milk powder brewing machine

A technology of mixing bin and brewing machine, which is applied to the field of milk powder blending bin and milk powder brewing machine, can solve the problems of limited effect, uncomfortable bubbles, low efficiency, etc., and achieves the effect of strong practicability and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The case will be further described in detail below in conjunction with the drawings and specific implementations.

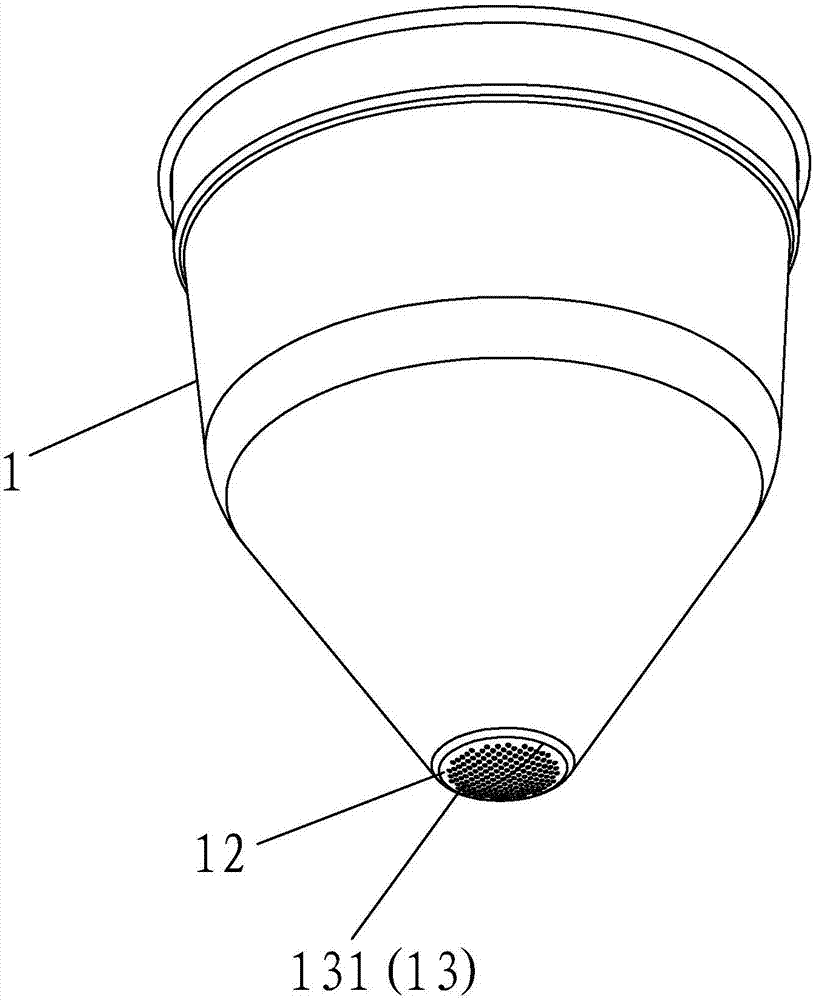

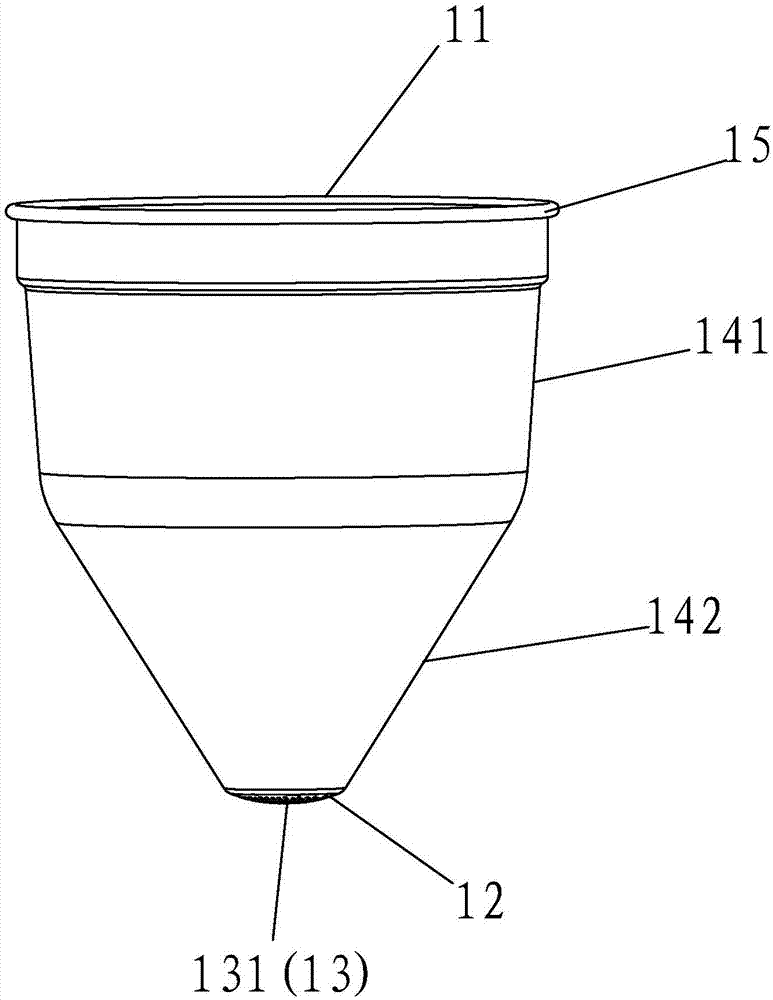

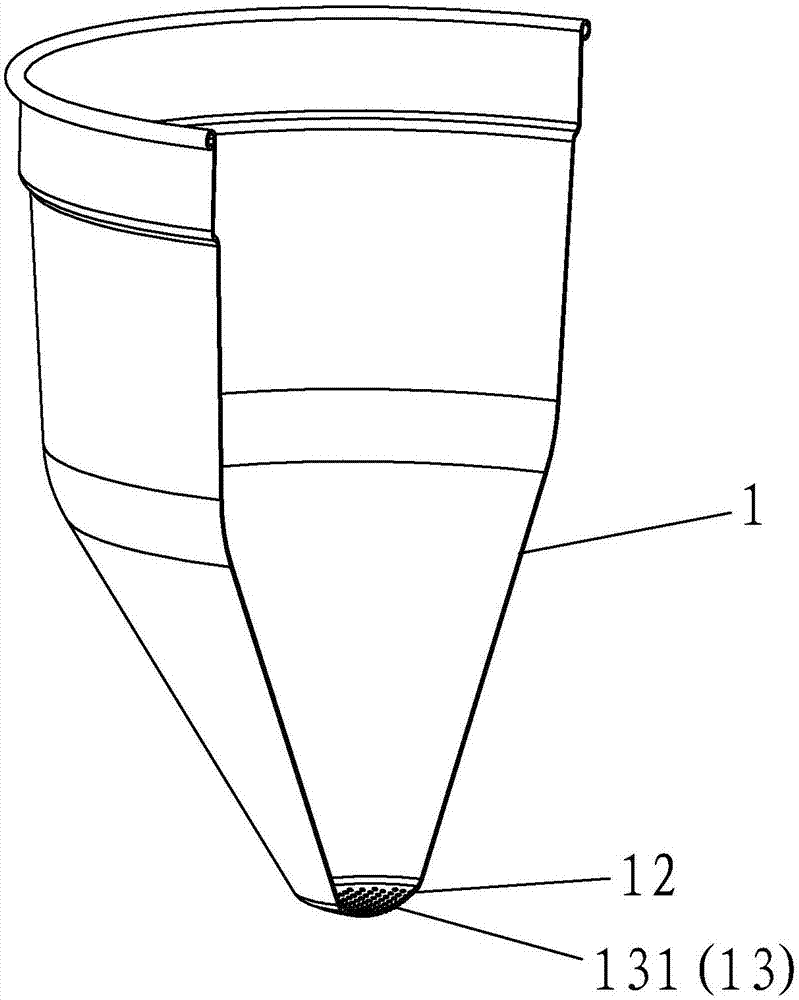

[0033] This case involves a milk powder brewing and mixing warehouse, such as Figure 1-3 As shown, there is a mixing bin body 1, and the upper end of the mixing bin body 1 is provided with an inlet 11, which is used to put the powdered milk into the mixing bin body 1.

[0034] The main original design point of this case is that the mixing bin body 1 has a bottom 12, the bottom 12 is closed, and the bottom 12 is provided with a hole group structure 13 as a milk outlet, and the hole group structure 13 consists of a plurality of densely arranged holes. A small hole 131 is formed.

[0035] The unique design of the milk outlet (hole group structure 13) of the bottom 12 will play different functions during different periods of the milk powder preparation process. When preparing milk powder, the milk powder is first sent into the mixing chamber body 1 and falls on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com