Aluminum powder coating for water-based paint and treatment process thereof

A water-based paint and treatment process technology, which is applied in the direction of inorganic pigment treatment, dyed organic silicon compound treatment, dyed polymer organic compound treatment, etc., can solve the problems of increasing cost, high price, unfavorable product promotion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. 40 parts of deoiling agent, 40 parts of 1# oily aluminum powder, add to the mixing tank at 500r / min*10min, add to the centrifuge to separate the aluminum powder and deoiling agent, after centrifugation, the aluminum powder is ready for use, and the deoiling agent is repeated use;

[0042] 2. Add 20 parts of hybrid siloxane resin, 6 parts of aluminum powder coating resin, and 40 parts of diluent into the mixing tank at 500r / min*10min, and filter through a 300-mesh filter to obtain the coating solution;

[0043] 3. Mix the coating solution and the centrifuged aluminum powder according to 1:1;

[0044] 4. Put the aluminum powder slurry into the autoclave, heat up to 50°C, stir at 500r / min for 30 minutes, and vacuum for 20 minutes to prepare the aluminum powder slurry for water-based coatings;

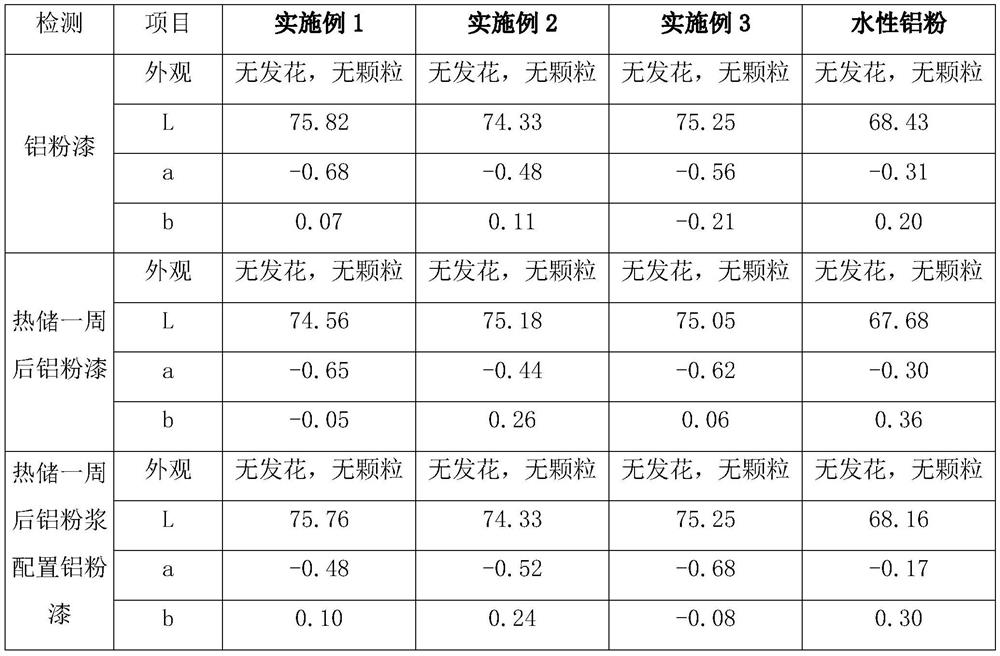

[0045] 5. Add the prepared 1# aluminum powder slurry to the water-based paint, spray the board, put the 1# aluminum powder slurry and the prepared aluminum powder paint into a 5...

Embodiment 2

[0047] 1. 40 parts of deoiling agent, 40 parts of 2# oily aluminum powder, add to the mixing tank at 500r / min*10min, add to the centrifuge to separate the aluminum powder and deoiling agent, after centrifugation, the aluminum powder is ready for use, and the deoiling agent is repeated use;

[0048] 2. Add 20 parts of hybrid siloxane resin, 6 parts of aluminum powder coating resin, and 40 parts of diluent into the mixing tank at 500r / min*10min, and filter through a 300-mesh filter to obtain the coating solution;

[0049] 3. Mix the coating solution and the centrifuged aluminum powder according to 1:1;

[0050] 4. Put the aluminum powder slurry into the autoclave, heat up to 50°C, stir at 500r / min for 30 minutes, and vacuum for 20 minutes to prepare the aluminum powder slurry for water-based coatings;

[0051] 5. Put the prepared 2# aluminum powder slurry into the water-based paint, spray the board, put the 1# aluminum powder slurry and the prepared aluminum powder paint into a...

Embodiment 3

[0053] 1. 40 parts of deoiling agent, 40 parts of 2# oily aluminum powder, add to the mixing tank at 500r / min*10min, add to the centrifuge to separate the aluminum powder and deoiling agent, after centrifugation, the aluminum powder is ready for use, and the deoiling agent is repeated use;

[0054] 2. Add 20 parts of hybrid siloxane resin, 6 parts of aluminum powder coating resin, and 40 parts of diluent into the mixing tank at 500r / min*10min, and filter through a 300-mesh filter to obtain the coating solution;

[0055] 3. Mix the coating solution and the centrifuged aluminum powder according to 1:1;

[0056]4. Put the aluminum powder slurry into the autoclave, heat up to 50°C, stir at 500r / min for 30 minutes, and vacuum for 20 minutes to prepare the aluminum powder slurry for water-based coatings;

[0057] 5. Put the prepared 3# aluminum powder slurry into the water-based paint, spray the board, put the 1# aluminum powder slurry and the prepared aluminum powder paint into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com