Preparation method of solid-state battery

A solid-state battery, solid-state electrolyte technology, applied in the manufacture of electrolyte batteries, lithium batteries, secondary batteries, etc., can solve the problems of easy deformation of cells, brittleness of solid-state batteries, flatulence, etc., to improve cycle stability and excellent compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

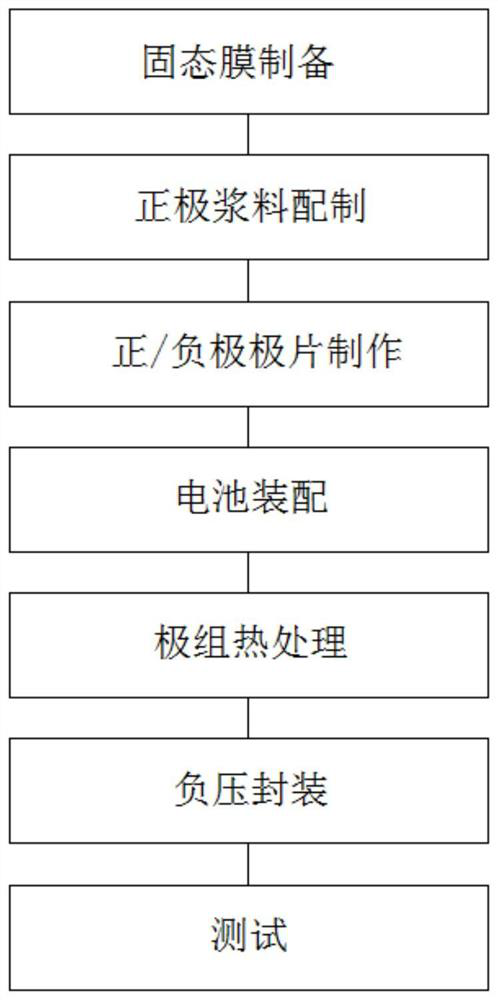

[0025] A preparation method of a solid-state battery, comprising preparation of a solid-state film, preparation of a positive electrode slurry, fabrication of a positive / negative electrode pole piece, battery assembly, heat treatment of a pole group, negative pressure packaging and testing;

[0026] The preparation method of the solid-state battery comprises the following steps:

[0027] Step 1, solid-state film preparation: the casting film slurry containing inorganic oxide ceramic powder and phase change agent is uniformly coated on aluminum foil, and then soaked in a solution of cyclodextrin / calixpyrrole lithium salt after non-solvent treatment , and finally dried to obtain a lithium ion solid electrolyte film;

[0028] Step 2, preparation of positive electrode slurry: preparation of positive electrode slurry for positive electrode coating;

[0029] Step 3, production of positive / negative pole pieces: for the production of positive / negative pole pieces, the positive pole p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com