Numerical control eight-axis double-chuck combined proximate matter intersecting line cutting device and method

An intersecting wire cutting and profile technology, applied in auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of difficult process processing, low material utilization rate, low processing efficiency, etc. Ease of collection and cleaning, resulting in improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

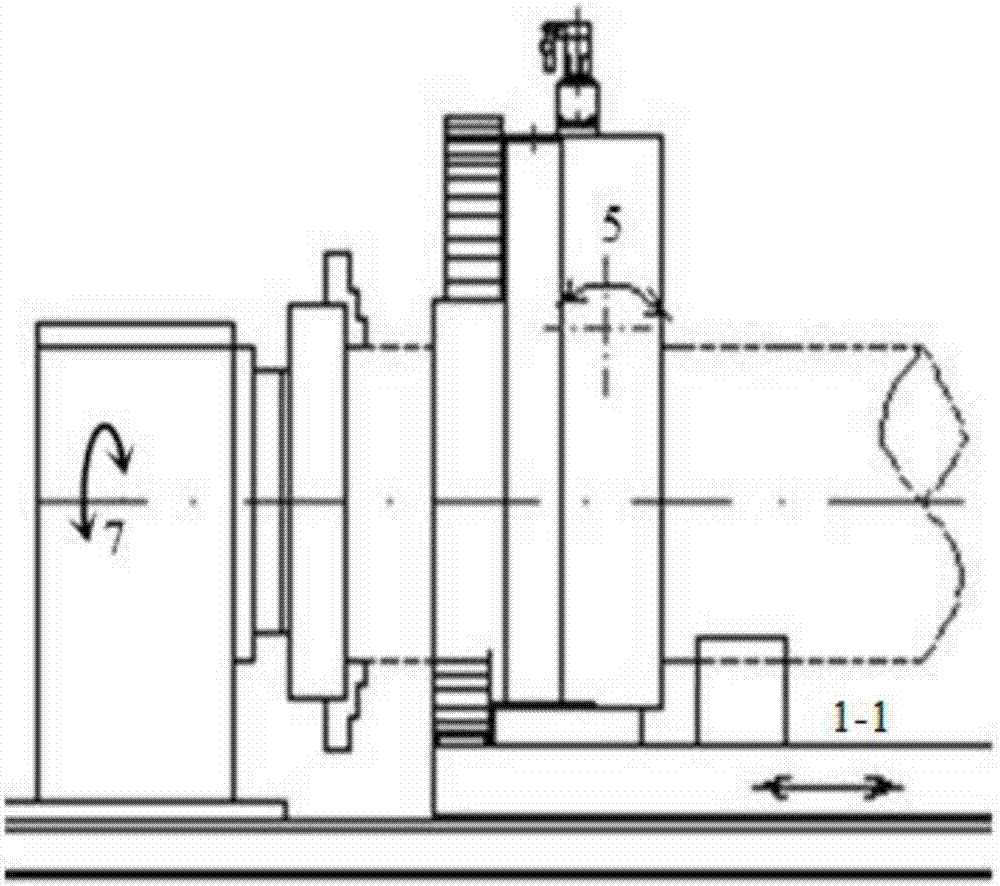

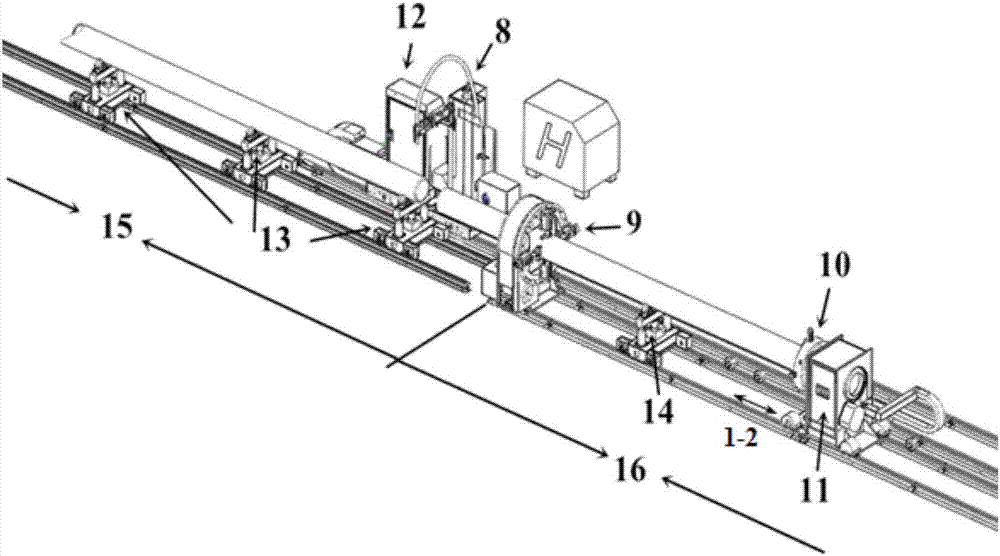

[0044] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

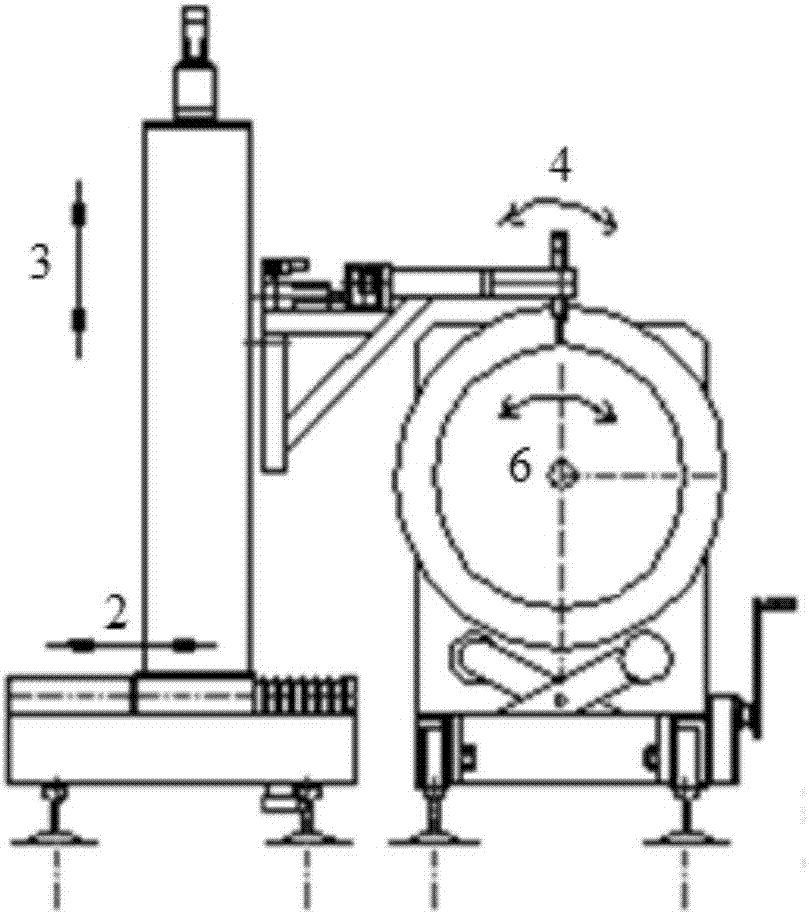

[0045] Such as image 3 As shown, a CNC eight-axis double-chuck combined profile intersecting line cutting device, the CNC eight-axis double-chuck combined profile intersecting line cutting device includes: a CNC eight-axis motion control system 12, a main cutting area 15, and an auxiliary cutting area 16;

[0046]The main cutting area 15 and the auxiliary cutting area 16 are provided with a common slide rail, and the cantilevered cutting head assembly 8 is provided on the public slide rail; the main cutting area 15 is provided with a main cutting area slide rail, and the main cutting area slide rail is provided with a main Auxiliary support trolley 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com