A hanger for wind power gearbox without outer ring cylindrical roller bearing

A technology for cylindrical roller bearings and wind power gearboxes, which is applied in the directions of load hanging components, transportation and packaging, etc., can solve the problem of the large weight of a single piece of cylindrical roller bearings without an outer ring, the limited wall thickness of the inner ring of the bearing, and the lifting tools. Lifting and other problems, to achieve the effect of solving lifting difficulties, saving assembly time, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

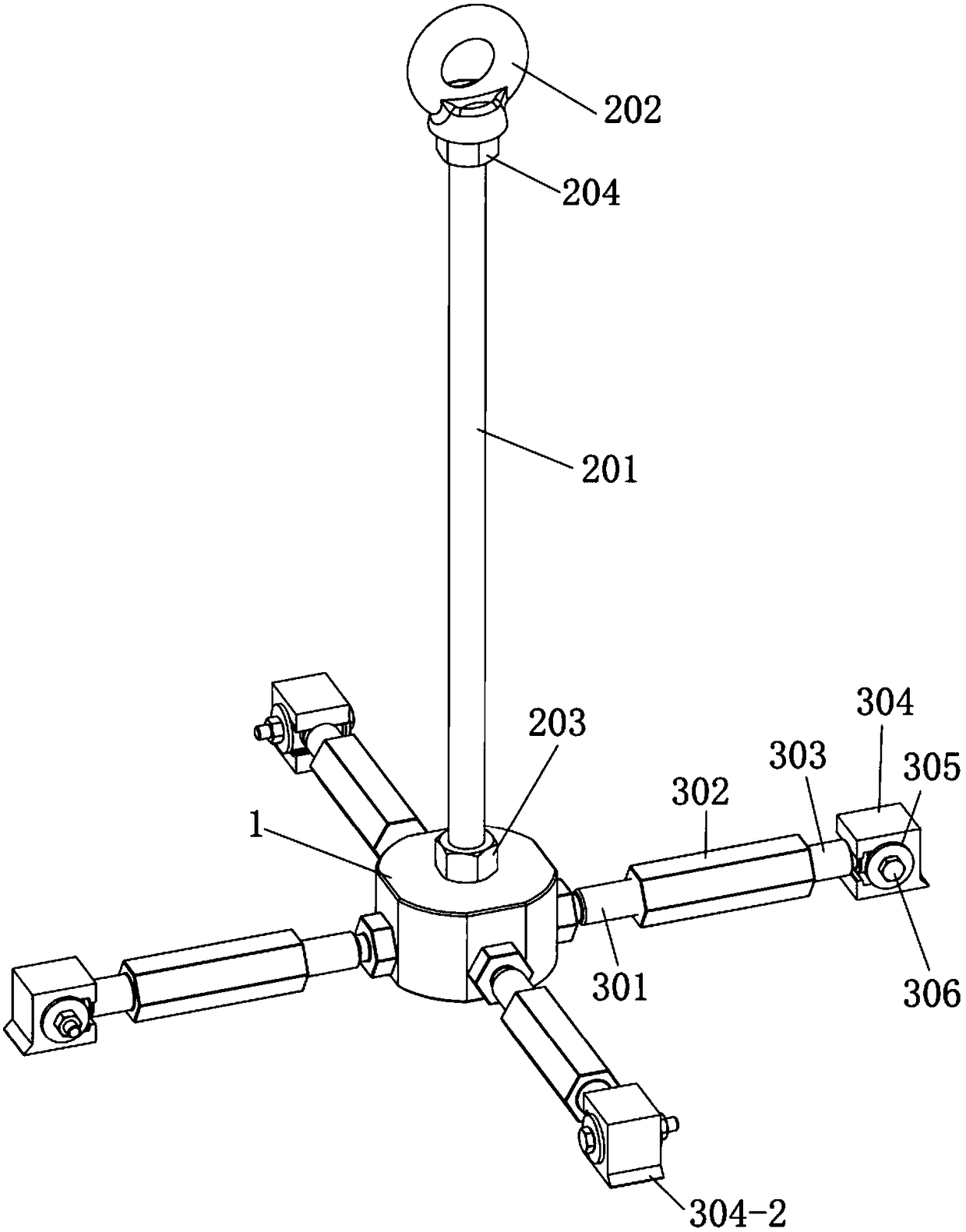

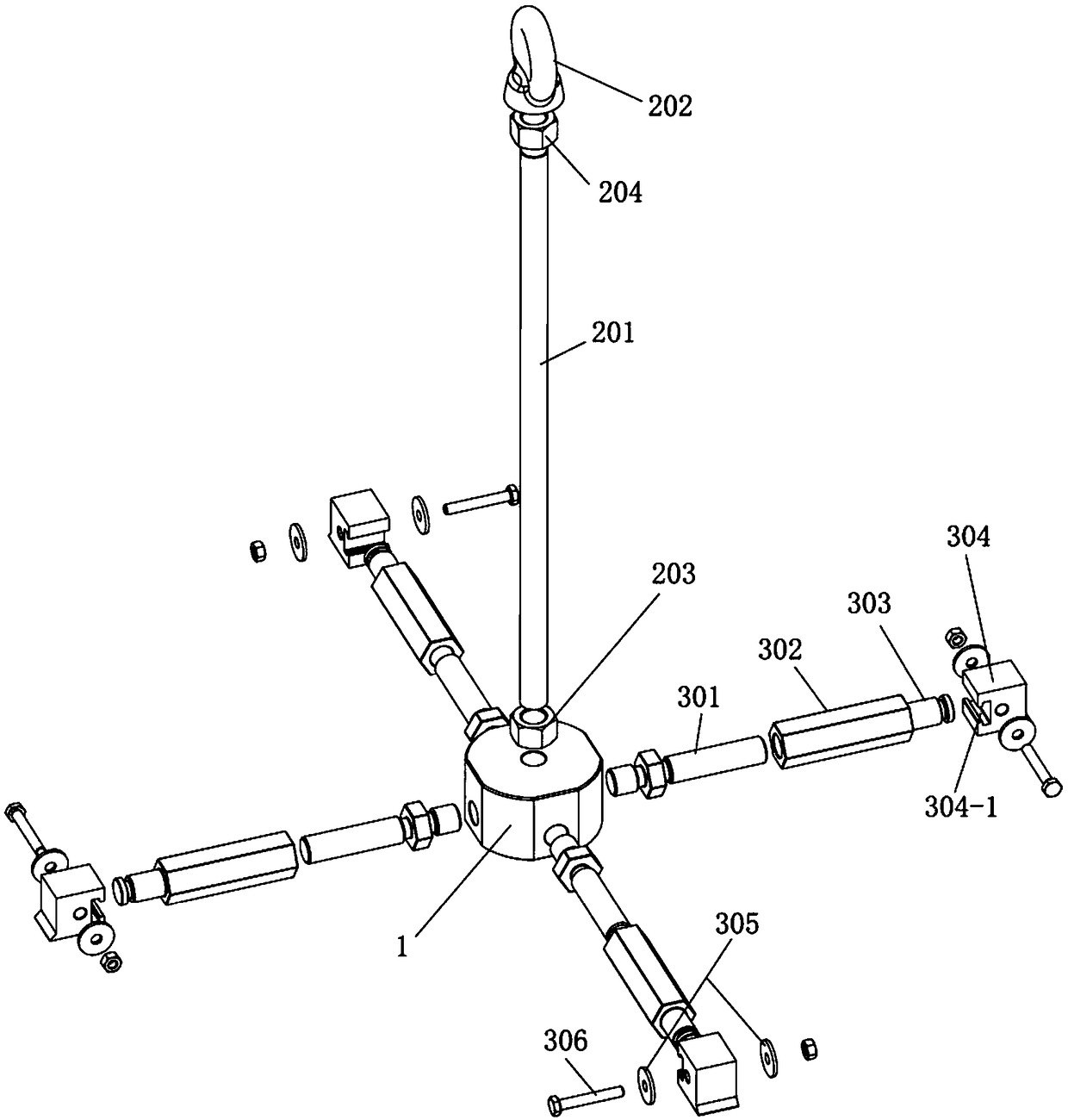

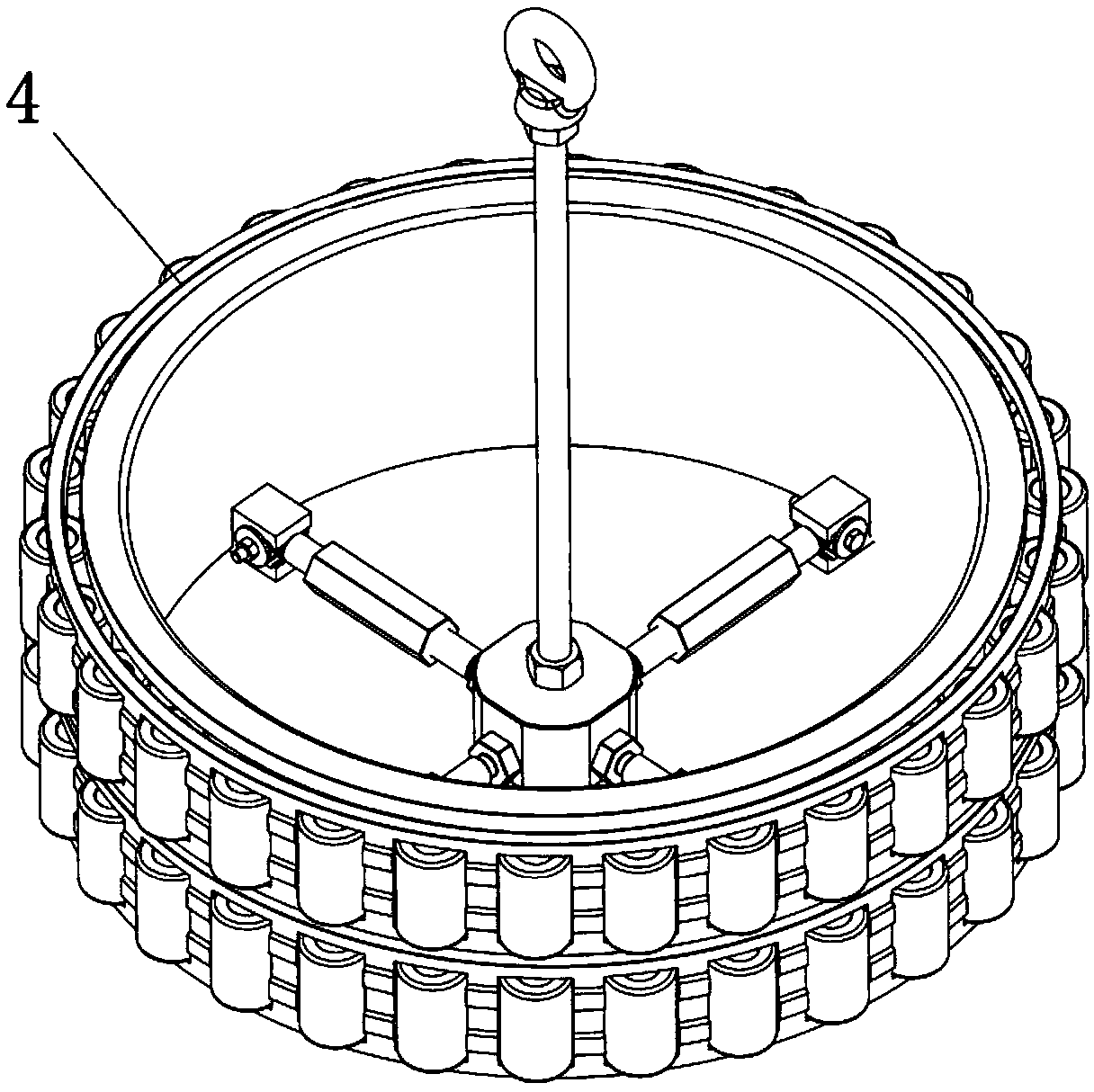

[0023] see Figure 1 to Figure 4 As shown, the wind power gearbox provided in this embodiment has no outer ring cylindrical roller bearing hanger, including a center flange 1, a suspension ring assembly and a bearing support; the suspension ring assembly includes a stud bolt 201, a nut suspension ring 202, a second Nut 203, third nut 204, one end of the stud bolt 201 is installed on the central part of the center flange 1 through the second nut 203, and the other end extends vertically upward through the third nut 204, and a nut suspension ring 202 is installed; The bearing support has four fixed distances and is threadedly connected to the periphery of the central flange 1 through respective joints 301, and is perpendicular to the center line of the central flange 1. Each bearing support includes joints 301 and first nuts 302 , a cylindrical tenon 303 and a corner 304 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com