Underground utility tunnel and construction method thereof

A technology of integrated pipe gallery and construction method, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of multi-chamber prefabrication construction, unsuitable application due to its large self-weight and volume, and shorten the construction period. The effect of large volume and low self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

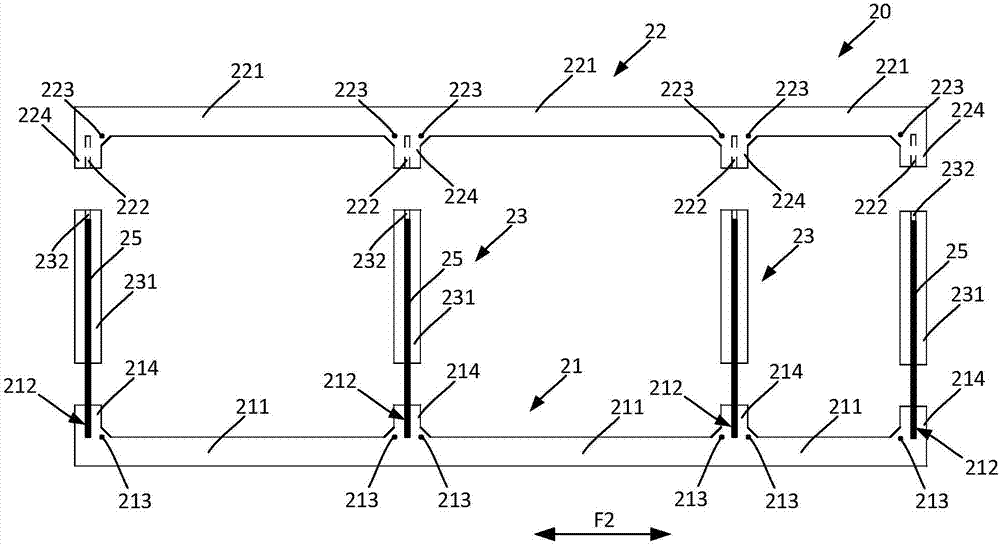

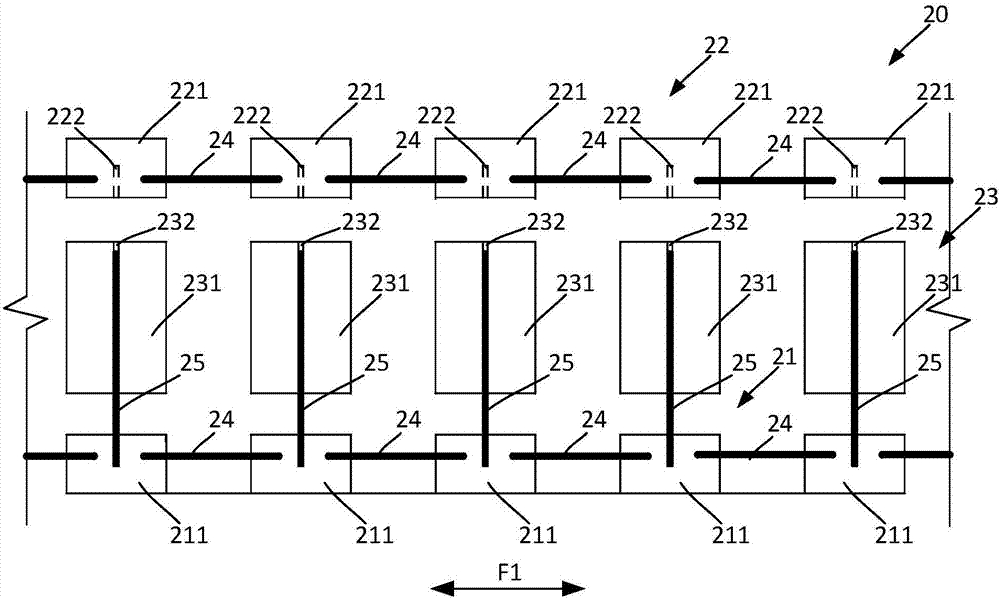

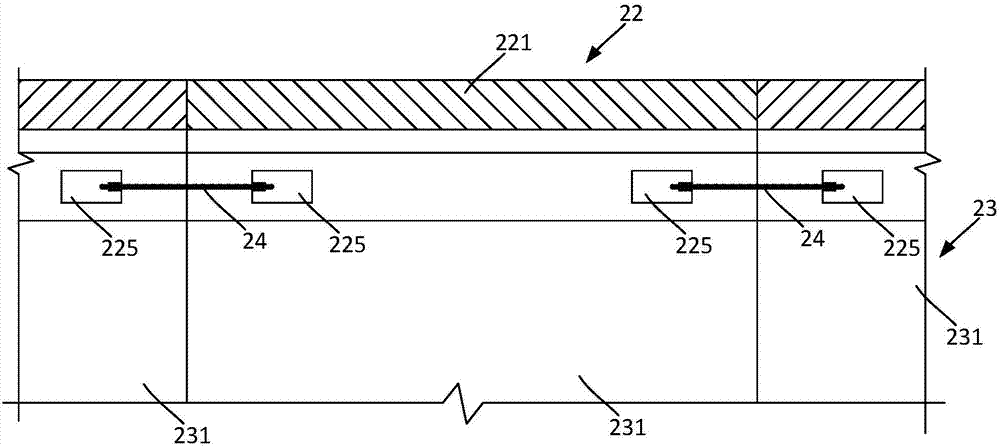

[0039] refer to figure 1 , the present invention provides an underground comprehensive pipe gallery and its construction method, which decomposes the cabin structure of the underground comprehensive pipe gallery into multiple sets of component blocks, and performs assembly operations through prefabricated components, avoiding the failure of large-volume components to be hoisted and For the problem of transportation, PC steel rods are used for rigid connection and PC steel strands are used for tension connection, so that various components can be integrated as a whole, which can ensure the bearing capacity and durability of the underground comprehensive pipe gallery. And after the components are split into blocks, the self-weight is small, and the installation and positioning are convenient. Compared with the cast-in-place structure, the constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com