Head device of a trapped vortex combustor and its working method

A combustion chamber and head technology, which is applied in the field of trapped vortex combustion chamber head devices, can solve the problems of complex air intake structure of the front wall of the cavity, unfavorable cooling of the front wall of the cavity, and unfavorable interaction between the cavity and the mainstream of the head. , to achieve the effect of achieving ignition performance and lean oil flameout performance, and reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

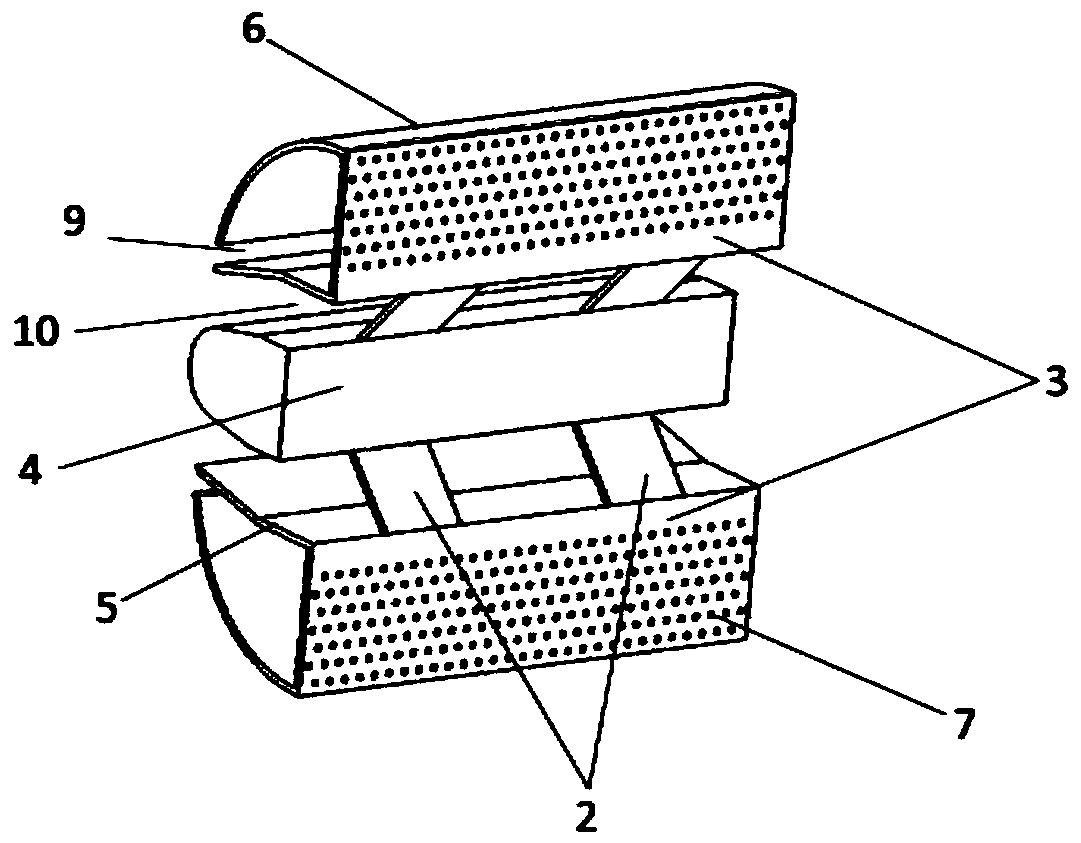

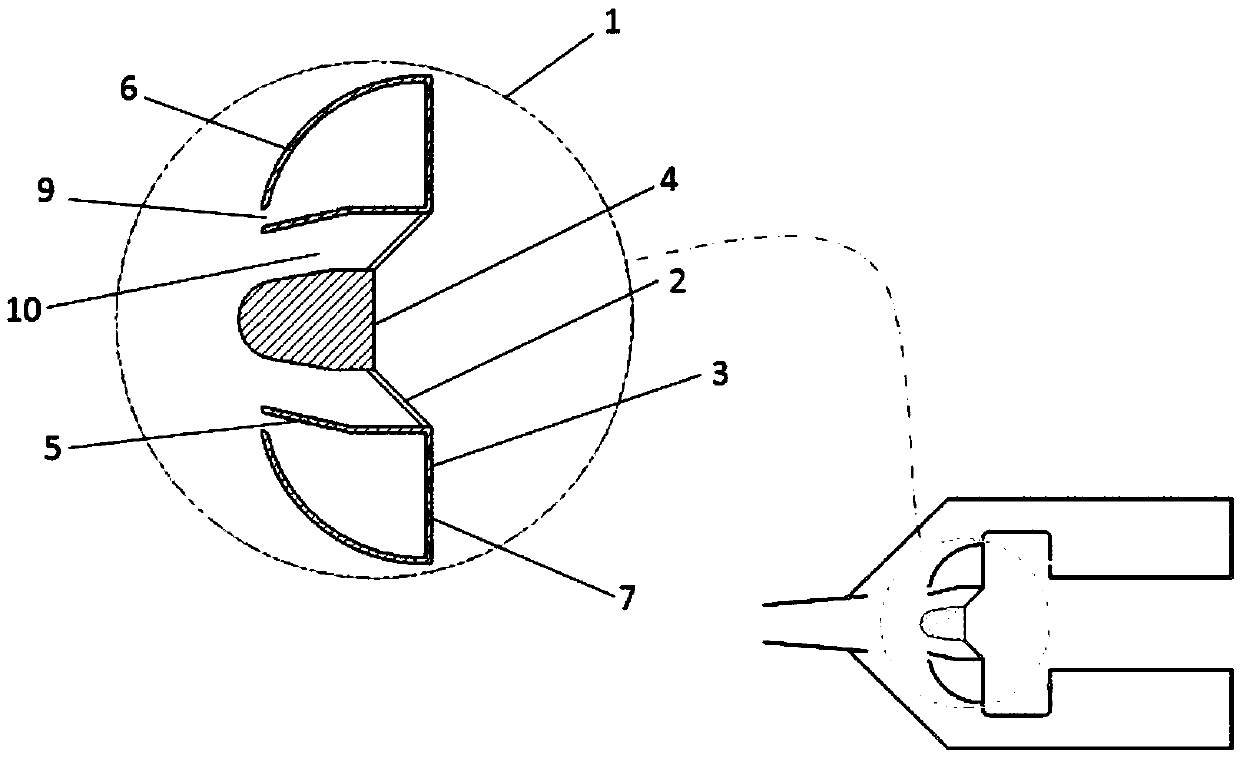

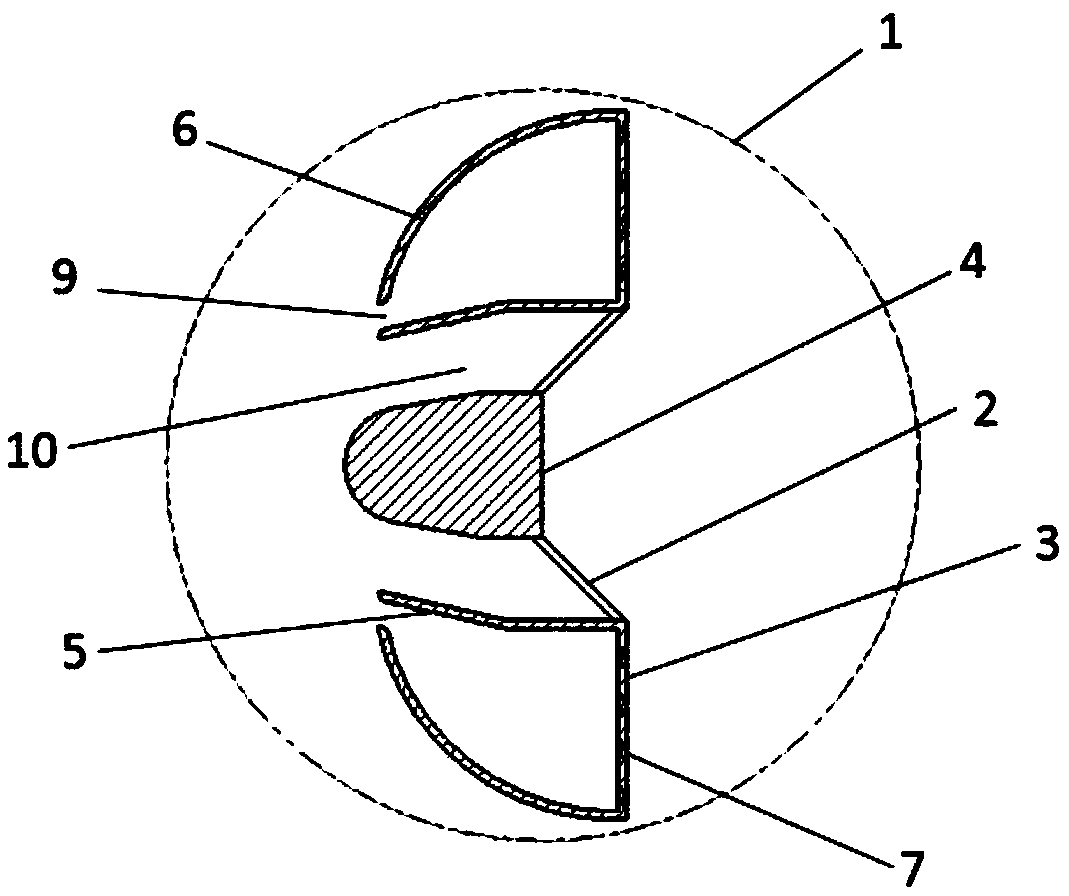

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Please refer to Figure 1 to Figure 4 As shown, a head device 1 of a trapped vortex combustion chamber of the present invention includes a central blunt body 4 , an inclined cross-fire plate 2 , a deflector 5 , a cavity front wall 3 , and a cap 6 . The central blunt body (4) is placed horizontally, with the arc facing forward and the horizontal plane facing backward, and the horizontal plane passing through the central axis is the symmetrical plane; the upper and lower ends of the horizontal plane behind the central blunt body 4 are respectively connected and inclined backward One end of the inclined cross-fire plate 2, the other end of the inclined cross-fire plate 2 is connected to the rear end of the deflector 5, and the deflector 5 is placed horizontally on the upper and lower sides of the central blunt body 4, and the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com