Vehicle air purifier

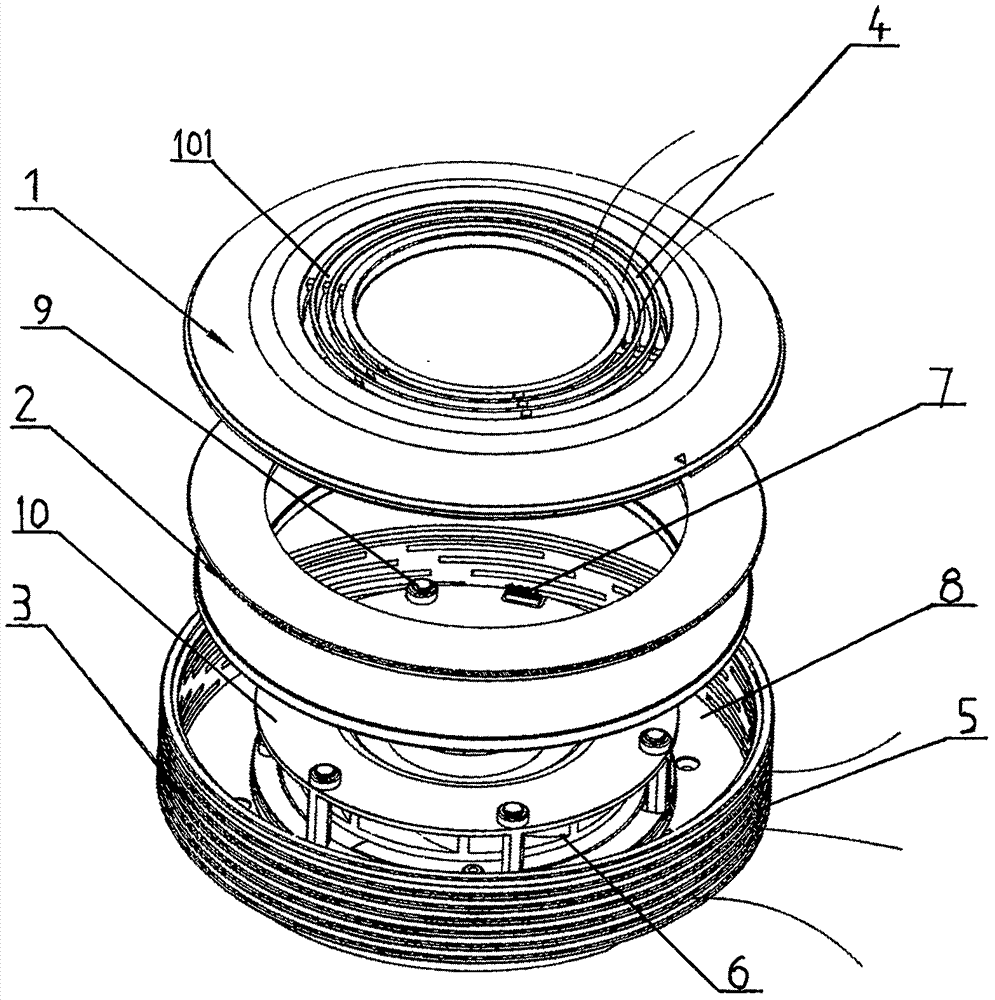

A technology for air purifiers and vehicles, applied in air treatment equipment, chemical instruments and methods, and chemicals for biological control, etc., can solve the problem of unreasonable filter design, time-consuming and laborious replacement of filter materials, and loud fan blade noise. and other problems, to achieve the effect of time-saving and labor-saving replacement of filter materials, smooth air outlet, and large air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

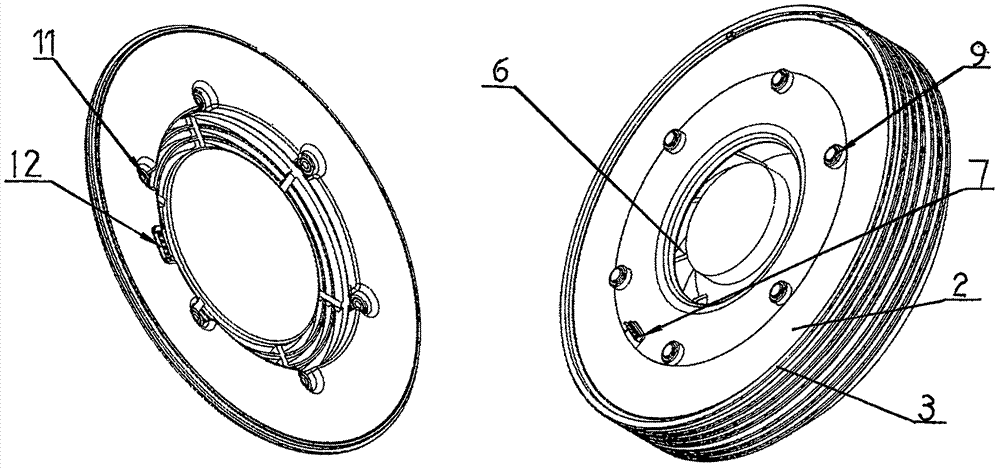

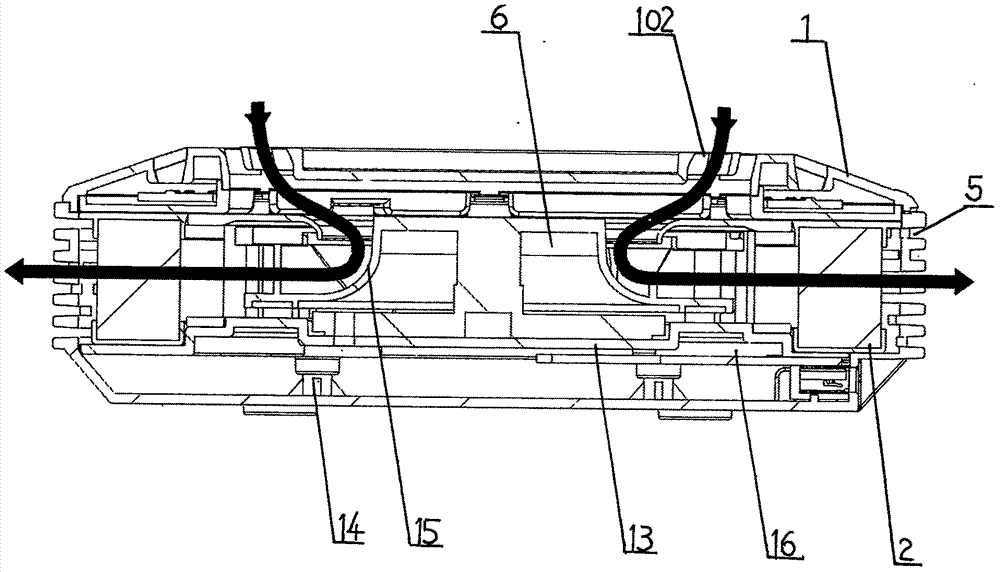

[0065] Embodiment 1: as Figure 5 to Figure 6 As shown, the composite filter assembly includes:

[0066] The upper ring plate 203 of the assembly is a circular ring plate. The upper ring plate of the assembly seals the upper end surface of the filter material.

[0067] The assembly lower ring plate 204, the assembly lower ring plate is a circular ring plate. The lower ring plate of the assembly seals the lower end surface of the filter material.

[0068] The filter material 201 is folded into a zigzag annular body connected end to end. The front end surface of the zigzag folded filter material at the air inlet end is a front ventilation support piece 207 . The rear end surface of the zigzag folded filter material is the rear ventilation support piece 209 . The intermediate filter material between the front and rear ventilation support sheets is an activated carbon mixed adsorption layer 206 . The outer fiber ring 208 is wrapped in the zigzag fold adjacent to the rear end...

Embodiment 2

[0074] Embodiment 2: as Figure 7 to Figure 8 As shown, the composite filter assembly includes:

[0075] The upper ring plate of the module is in the form of a circular ring plate. The lower end surface of the upper ring plate of the assembly is provided with a recessed card slot 212 corresponding to each filter screen plate, and the recessed card slot seals or opens the upper end of each filter screen plate.

[0076] The lower ring plate of the assembly is a ring plate, and the upper end surface of the lower ring plate of the assembly is fixed at a distance from the first filter screen plate 210, the second filter screen plate 218, the third filter screen plate 221, the fourth filter screen plate 220, and the fifth filter screen plate. The lower end of the screen plate 219 and the sixth filter screen plate 211. The spaces between the upper and lower ring plates of the assembly and the first to sixth filter screen plates sequentially form the first filter chamber 216, the se...

Embodiment 3

[0081] Embodiment 3: as Figure 9 As shown, the composite filter assembly includes:

[0082]The lower end surface of the upper ring plate of the component is provided with a recessed card slot corresponding to each filter screen plate, and the recessed card slot seals or opens the upper end of each filter screen plate.

[0083] The lower ring plate of the assembly is a circular ring plate, and the upper end surface of the lower ring plate of the assembly is fixed at a distance from the lower ends of the first to sixth filter screen plates. The lower surface of the first filter panel, the upper surface of the second filter panel, the lower surface of the third filter panel, the upper surface of the fourth filter panel, the lower surface of the fifth filter panel, the sixth filter panel The upper surface of the mesh part is the mesh part 223, and the filter screen plate surface on the upper part of the mesh part is the sealing part 222.

[0084] Spaces between the upper and lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com