Multifunctional efficient powder stirrer

A mixer and multi-functional technology, applied in the field of multi-functional and high-efficiency powder mixers, can solve the problems of low mixing efficiency, powder agglomeration due to moisture, and inability to store powder, and achieve the effect of improving mixing efficiency and avoiding melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

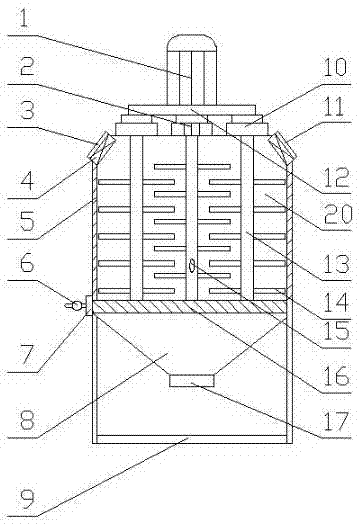

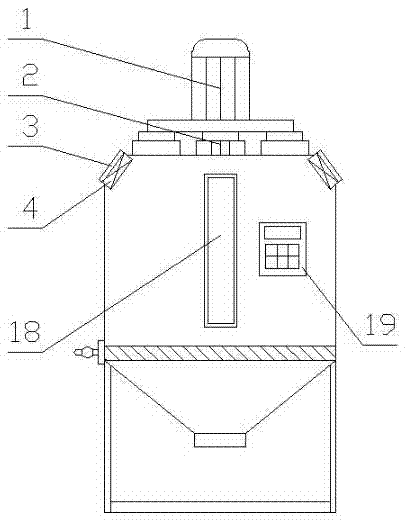

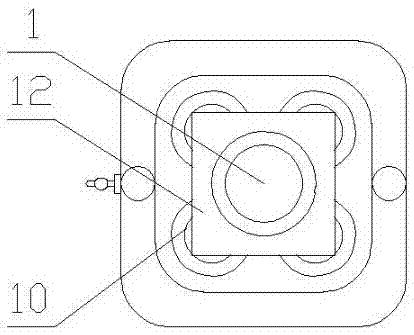

[0011] A multifunctional high-efficiency powder mixer, characterized in that it includes a stirring motor 1, a reverse rotation shaft 2, a feed port 3, a sealing valve 4, a refrigeration pipe 5, a pull handle 6, a sealing strip 7, a hopper 8, and a bracket 9. Forward rotating shaft 10, mixture inlet 11, transmission mechanism 12, stirring shaft 13, stirring blade 14, temperature sensor 15, moisture-proof baffle 16, discharge port 17, observation window 18, temperature controller 19, Stirring chamber 20, an observation window 18 is installed on one side of the stirring chamber 20, a temperature controller 19 is installed on one side of the observation window 18, a reverse transmission shaft 2 is installed above the mixing chamber 20, and four forward transmission shafts 10 are installed around the reverse transmission shaft 2 , the stirring shaft 13 is installed below the forward transmission shaft 10 and the reverse transmission shaft 2, the stirring blade 14 is installed on th...

Embodiment 2

[0013] Open the sealing valve 4, put the powder to be mixed into the mixing chamber 20 through the feed port 3 and the mixture feeding port 11, after the powder is poured, close the sealing valve 4, turn on the power of the stirring motor 1, and the stirring motor 1 passes through the transmission mechanism 12 drives the equipment to run, the stirring shaft 13 under the reverse rotation shaft 2 rotates reversely, the stirring shaft 13 below the forward rotation shaft 10 rotates forward, and the stirring blade 14 stirs the plastic powder. If the temperature of the plastic powder is too high during the stirring process , then the temperature-sensing probe 15 triggers the temperature controller 19, and the refrigeration pipe 5 runs to cool down the plastic powder to prevent the powder from melting. After mixing, if there is no storage device, the power supply can be cut off. The present invention can store the powder. The moisture-proof baffle 16 is pulled out through the pull han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com