Anti-extreme pressure lubricant additives and lubricants

A lubricating oil additive and lubricating oil technology, applied in the chemical field, can solve problems such as metal surface corrosion, component emissions, chemical pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Utilize the method for the embodiment of the present invention to synthesize oil-soluble nano-hydroxy magnesium silicate, the specific process is as follows:

[0059] 1) Weigh 2.05g of sodium nitrate, 0.41g of sodium silicate, and 10.3g of sodium hydroxide and dissolve them in 200ml of water, and stir evenly;

[0060] 2) The above mixed solution was heated to 180 degrees and kept for 24 hours, then cooled to room temperature to obtain a white liquid;

[0061] 3) Centrifuge the above white liquid to obtain a white precipitate, which is dissolved in water and ethanol to wash the white precipitate alternately;

[0062] 4) Weigh 2.0 g of the white precipitate and dissolve it in 15 ml of ethanol, heat to 70 degrees, add 0.1 g of SG-SiF17 silane coupling agent dropwise, stir, react for 2 hours, cool to room temperature, and obtain a white liquid;

[0063] 5) centrifuging the white liquid obtained in step 4) to obtain a white precipitate;

[0064] 6) Washing the white precip...

Embodiment 2

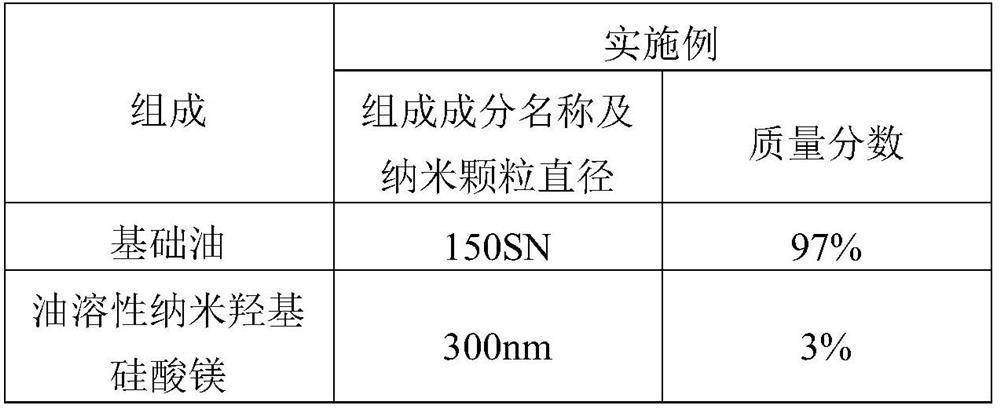

[0066] The oil-soluble nano-hydroxymagnesium hydroxysilicate prepared in the example was measured according to the mass fraction of the raw materials shown in Table 1, and the raw materials were mixed and subjected to ultrasonic treatment to obtain the lubricating oil additive product of this example.

[0067]

[0068] The lubricating oil additive product is added into the lubricating oil to obtain the lubricating oil containing the oil-soluble nano-hydroxy magnesium silicate with a mass fraction of three thousandths.

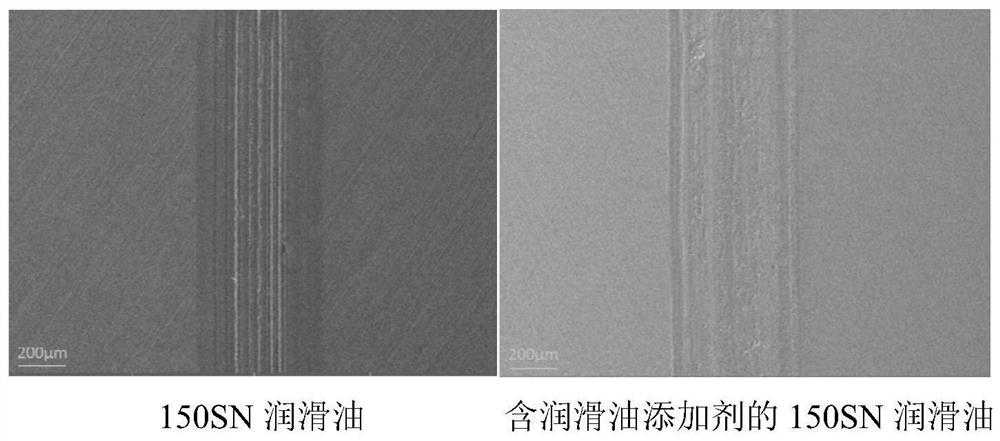

[0069] The SRV friction and wear performance is used to evaluate the extreme pressure and anti-wear characteristics of lubricating oil. The experimental conditions are carried out in accordance with the experimental conditions of the ASTM D7421 test standard for extreme pressure testing of lubricating oil. The specific parameters are: frequency 50Hz, amplitude 2mm, temperature 50°C, friction pair GCr15. Continuous loading is adopted, and 100N is loaded every...

Embodiment 3

[0073] According to the mass fractions of raw materials shown in Table 3, according to the method of the present invention, the raw materials are mixed and ultrasonically treated to obtain the lubricating oil additive product of this embodiment.

[0074]

[0075] The lubricating oil additive product is added to the lubricating oil to obtain the lubricating oil containing oil-soluble nano-hydroxy magnesium silicate with a mass fraction of 5 per thousand.

[0076] SRV4 friction and wear performance was used to evaluate the extreme pressure and antiwear properties of lubricating oil. The experimental conditions were carried out in accordance with the experimental conditions of ASTM D7421, the extreme pressure test standard for lubricating oil, and the specific parameters were: frequency 50Hz, amplitude 2mm, temperature 50°C, friction pair GCr15. Continuous loading is adopted, and 100N is loaded every two minutes until the lubrication fails. The base oil was compared with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com