Patents

Literature

40results about How to "Solve pollution discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201AAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

Hot-blast furnace pipe packing material and preparation method therefor

ActiveCN107698266AImprove high temperature performanceGood solid state sintering propertiesBlast furnace detailsProcess efficiency improvementResource utilizationMullite

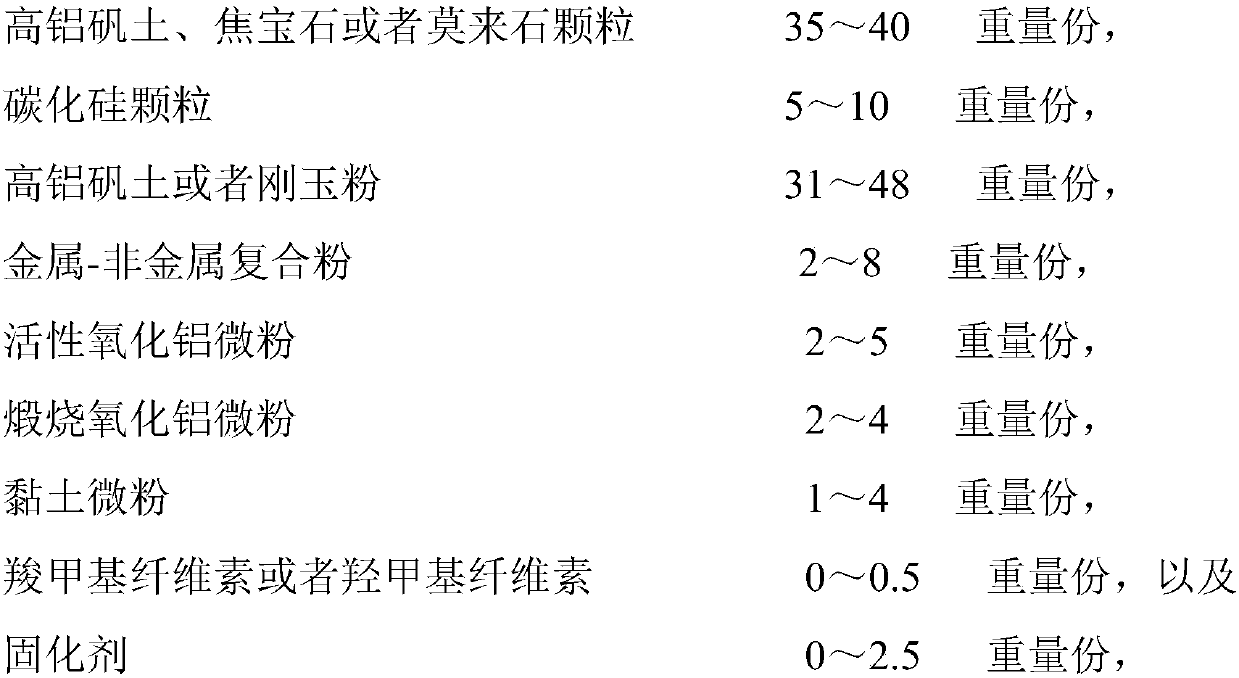

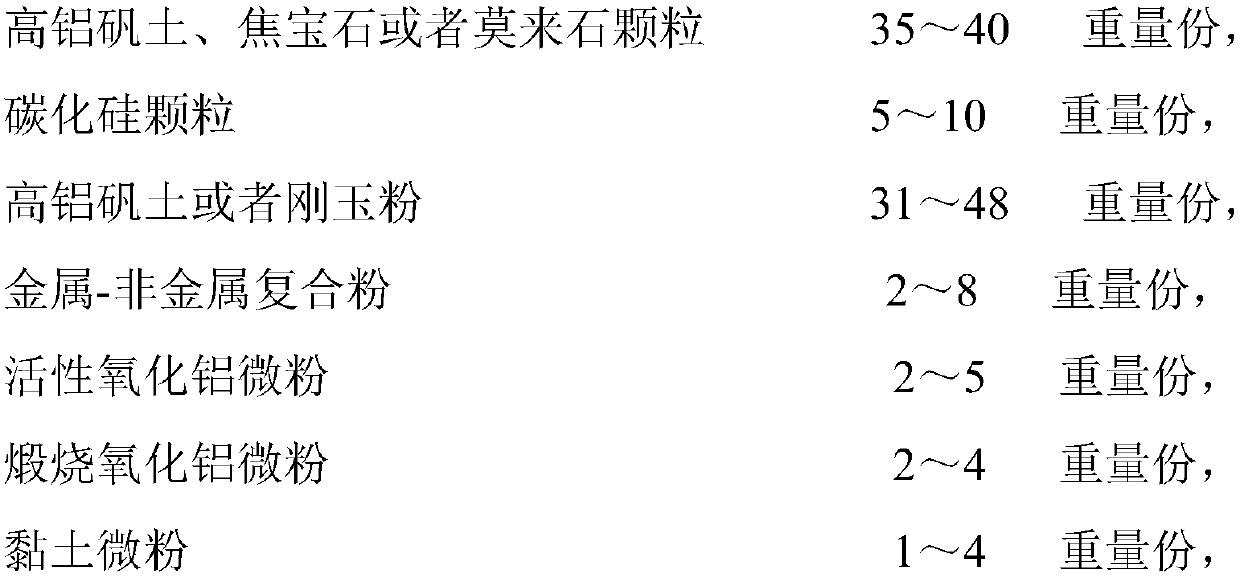

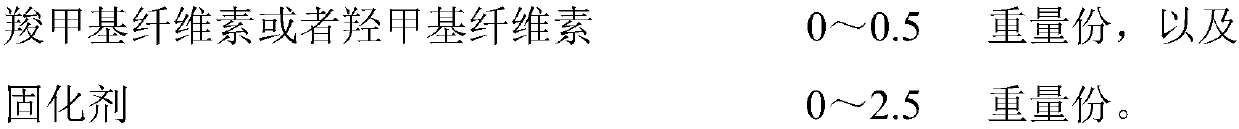

The invention discloses a hot-blast furnace pipe packing material and a preparation method therefor. The packing material is prepared from the ingredients in parts by weight: 100 parts of dry mattersand 10-25 parts of silica sol, wherein the 100 parts of dry matters comprise high bauxite, flint clay or mullite particles, silicon carbide particles, high bauxite or corundum powder, metal-nonmetal composite powder, activated alumina micropowder, calcined alumina micropowder, clay micropowder, carboxymethyl cellulose or hydroxymethyl cellulose and a curing agent. The packing material disclosed bythe invention is pollution-free to environments, is good in fluidity in construction time, is not prone to settlement, can be thoroughly packed into small slits during pressed-in repair, can be constructed at high temperatures and can also be cured at normal temperatures; the packing material can be tightly bonded to a material of a pressed-in area; the packing material has good strength propertyat all temperatures; the packing material has low linear shrinkage in service temperature intervals and has good thermal shock stability; and industrial wastes of other industries are utilized, so that the utilization ratio of resources is increased.

Owner:CHINA JINGYE ENG +2

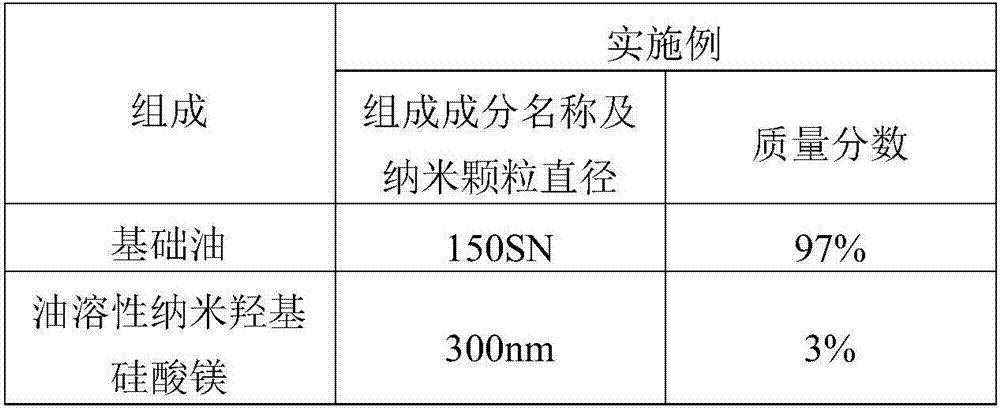

An extreme-pressure-resisting lubricating oil additive and lubricating oil

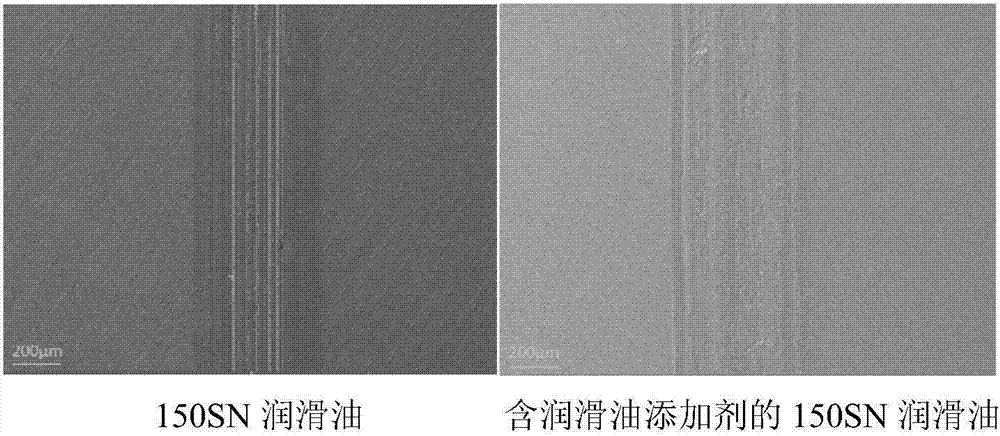

A lubricating oil additive and lubricating oil are disclosed. The additive includes 70-99 parts by mass of base oil and 1-30 parts by mass of oil-soluble magnesium silicate hydroxide. The additive is stable in performance, and the cost is low. The additive is free of sulfur, phosphorus and other elements, thus avoiding pollutant discharge problems of sulfur, phosphorus and other elements. The additive, under boundary lubrication conditions, can effectively prevent direct contact between a friction pair, reduce abrasion, prevent clinkering, seizing and stuck phenomena, and scratches on surfaces of the friction pair, and greatly improve extreme pressure resistance of the lubricating oil.

Owner:TSINGHUA UNIV

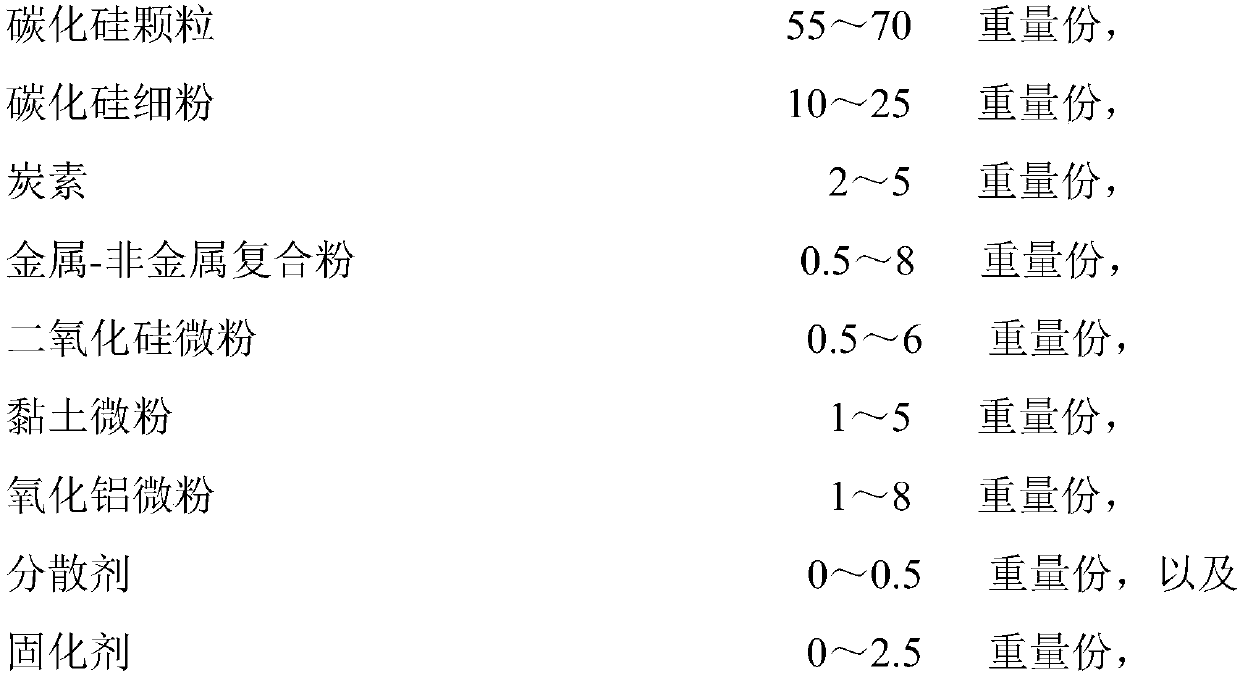

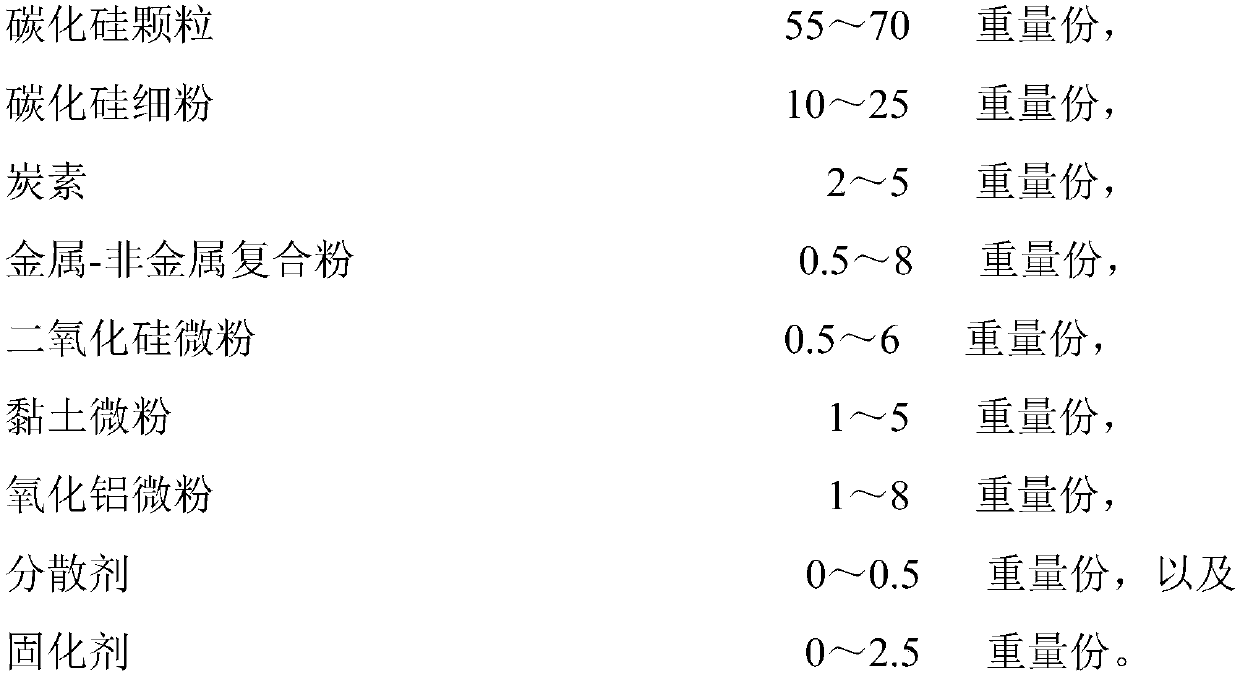

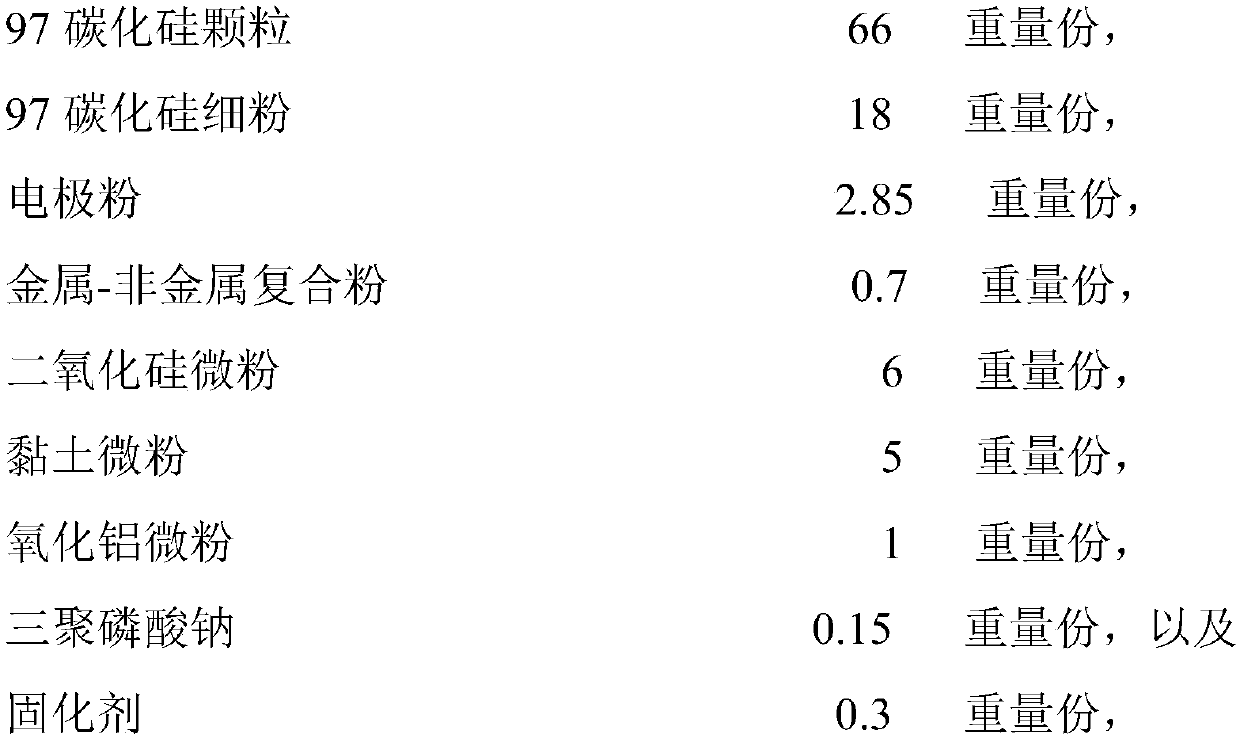

Blast furnace bottom joint filler and preparation method thereof

ActiveCN110627505AHigh thermal conductivity and high strengthImprove liquidityHigh densityResource utilization

The invention discloses a blast furnace bottom joint filler. The joint filler comprises, by weight, 100 parts of dry materials and 10-25 parts of a binder, wherein 100 parts of the dry materials include silicon carbide particles, fine silicon carbide powder, carbon, a metal-nonmetal composite powder, a silicon dioxide micro-powder, a clay micro-powder, an aluminum oxide micro-powder, a dispersantand a curing agent. The invention further discloses a preparation method of the blast furnace bottom joint filler. The blast furnace bottom joint filler has a high heat conductivity coefficient, can effectively transfer heat, has a high strength index and a high density, has no pollution to the environment, is easy to construct, can fully fill joints, can closely combine with a material for filling the area, can be constructed at a high temperature, also can be constructed and solidified at normal temperature, has a small linear change rate and a good thermal shock stability in a use temperature interval, and improves the resource utilization rate by using wastes in other industries.

Owner:CHINA JINGYE ENG +2

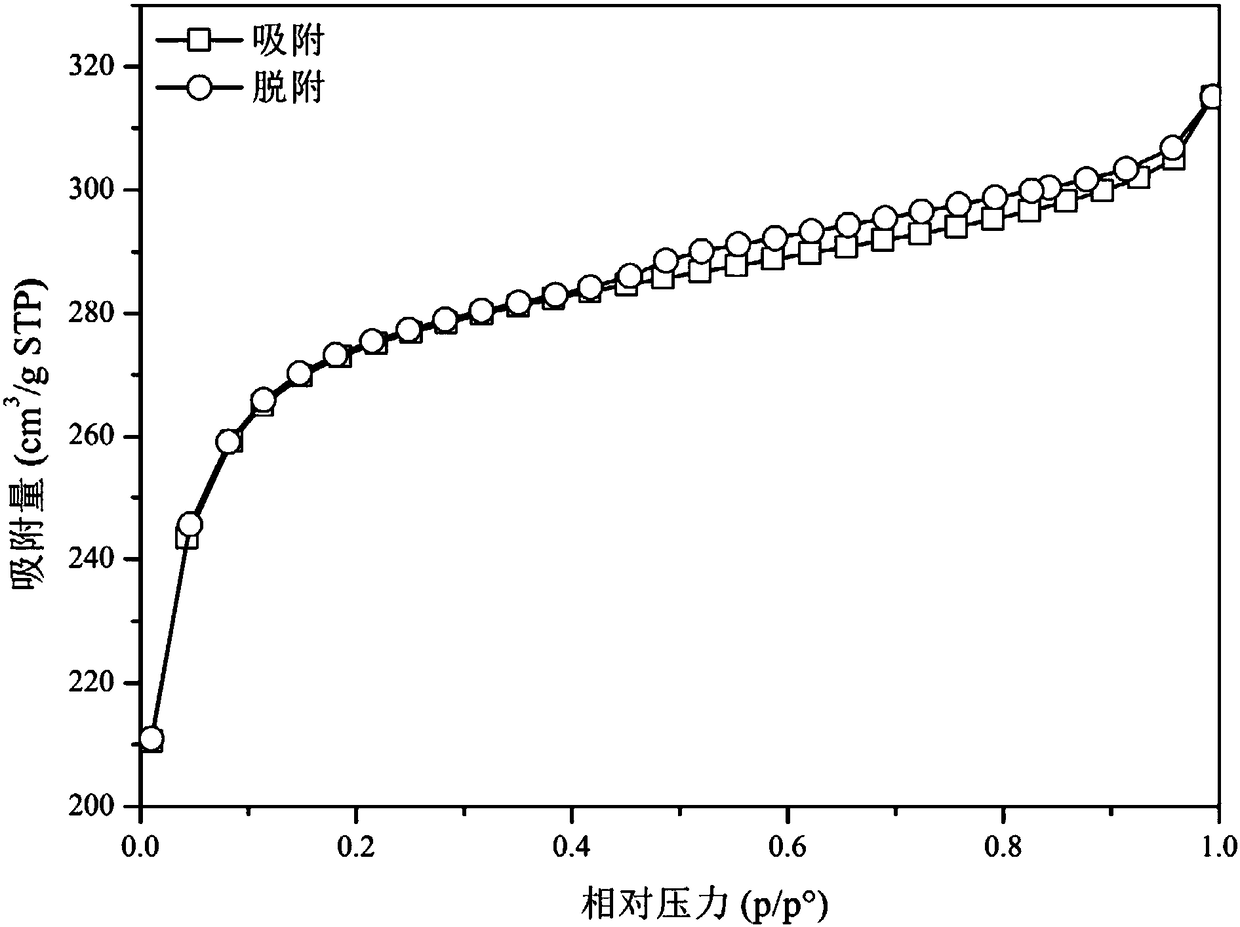

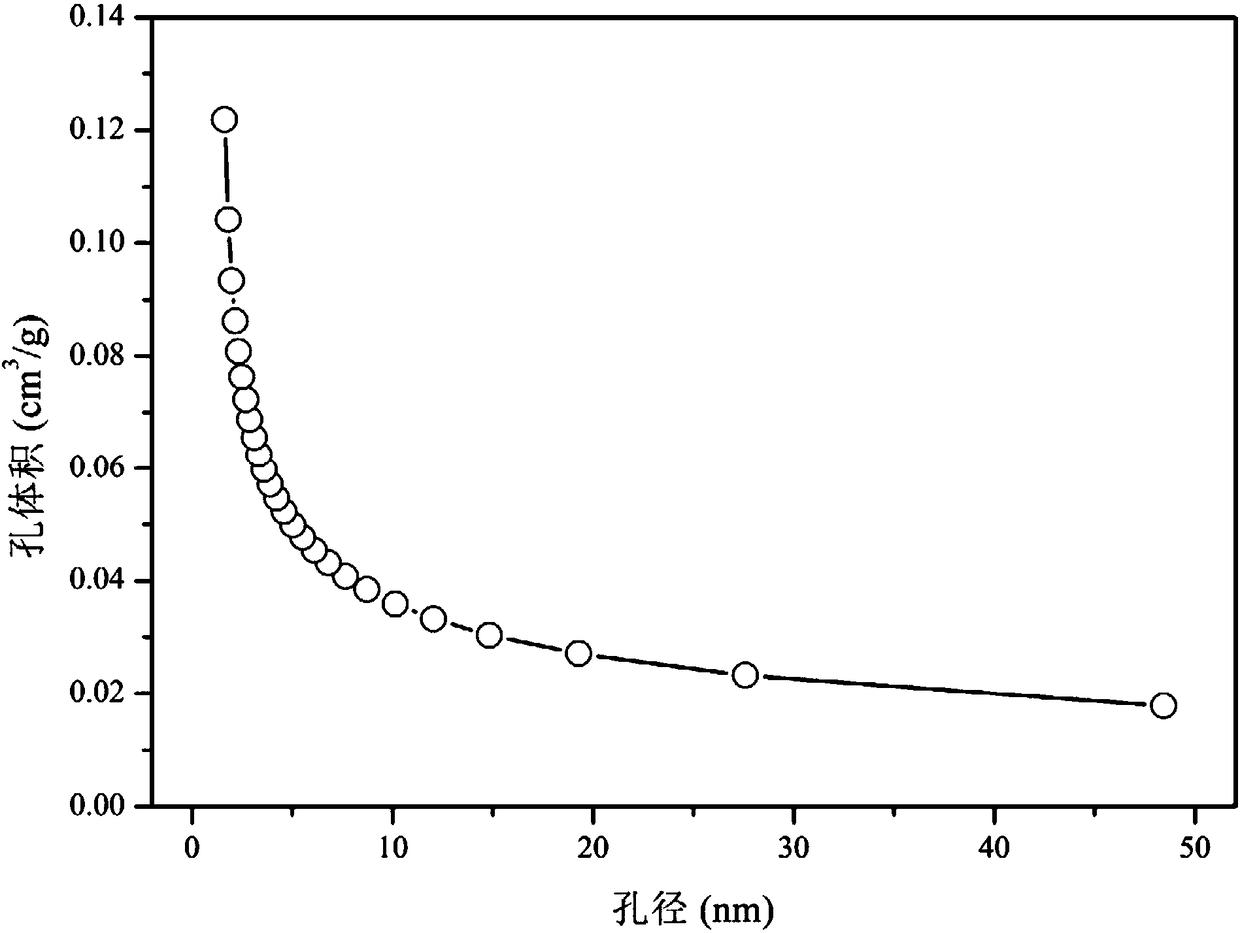

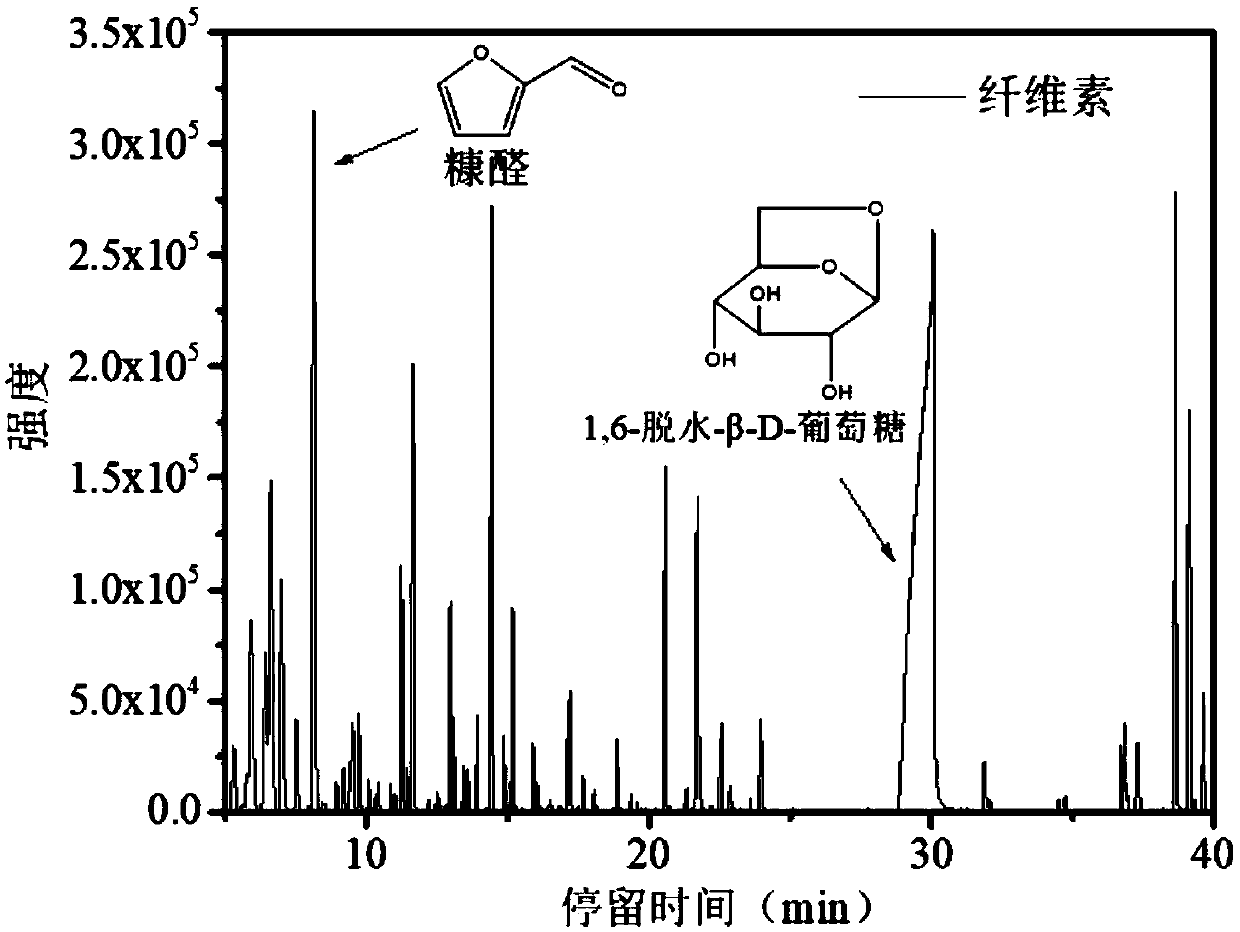

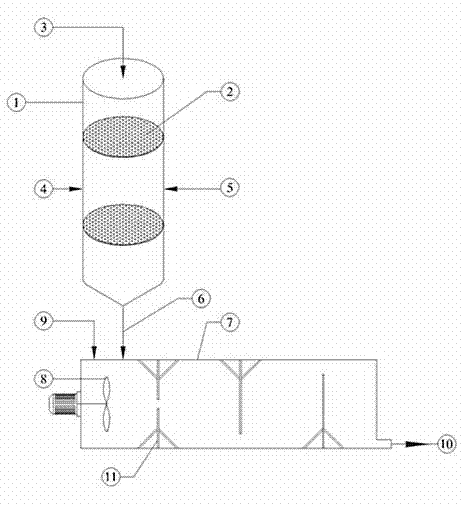

Tin loaded porous carbon based solid acid catalyst as well as preparation method and application thereof

InactiveCN108325515ATurn waste into treasureSolve pollution dischargeOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPorous carbonCarbonization

The invention discloses a tin loaded porous carbon based solid acid catalyst as well as a preparation method and application thereof. According to the preparation method, biomass waste and active materials are soaked in a tin salt water solution; then, the soaked biomass waste materials are taken out and dried and are next put into a tubular furnace; carbonization is performed to obtain carbonizedmaterials; then, the carbonized materials are put into water to be stirred; filtering and washing are performed by a sand core funnel; the tin loaded porous carbon based solid acid catalyst is obtained. After the tin loaded porous carbon based solid acid catalyst is mixed with carbohydrate and solvents, the mixture is put into a hydrothermal reactor for reaction; reaction products are subjected to separation and purification to obtain furfural. The tin loaded porous carbon based solid acid catalyst provided by the invention has greater specific surface area, greater hole size and higher aciddensity; in the process of catalytic preparation of furfural, the catalyst shows excellent solid catalysis performance; the furfural yield is 40 to 90 percent; the relatively good circulation utilization performance is realized.

Owner:SOUTH CHINA UNIV OF TECH

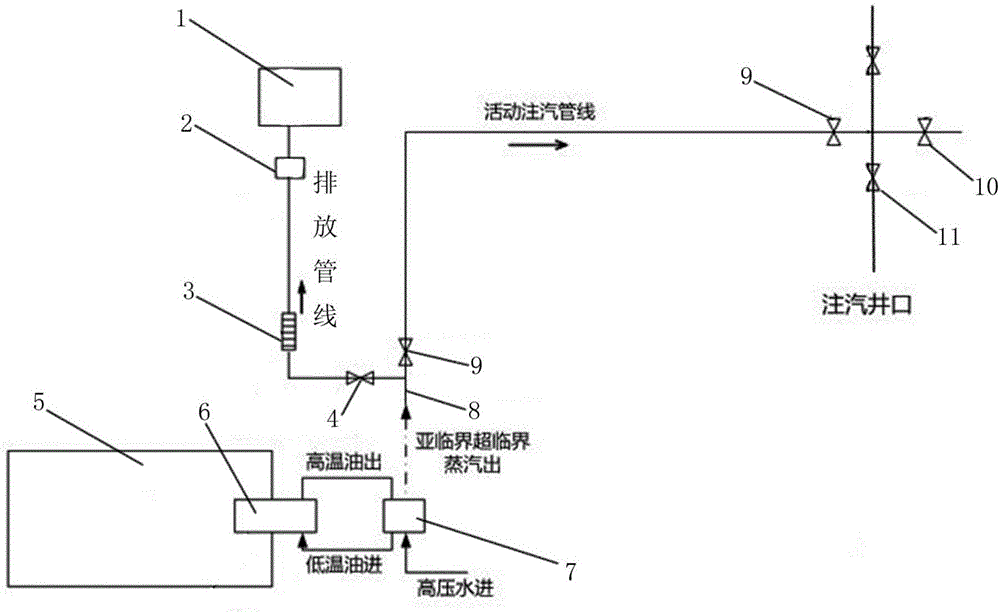

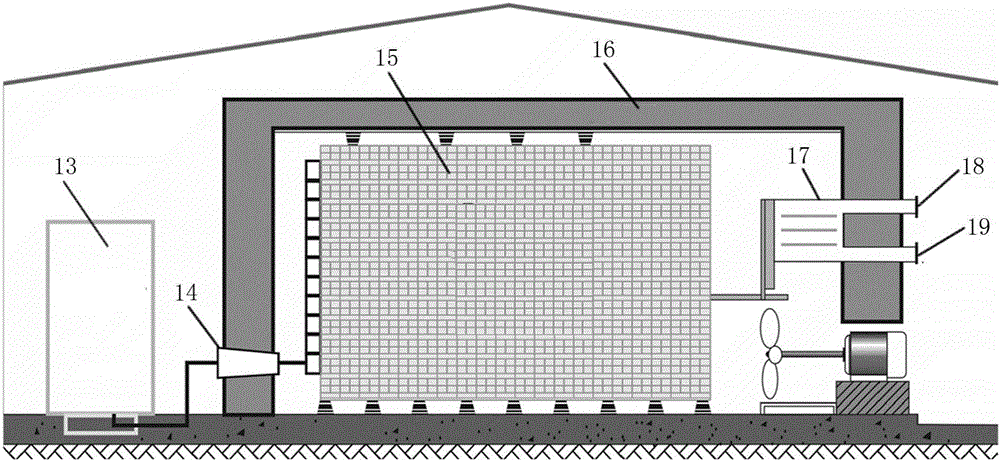

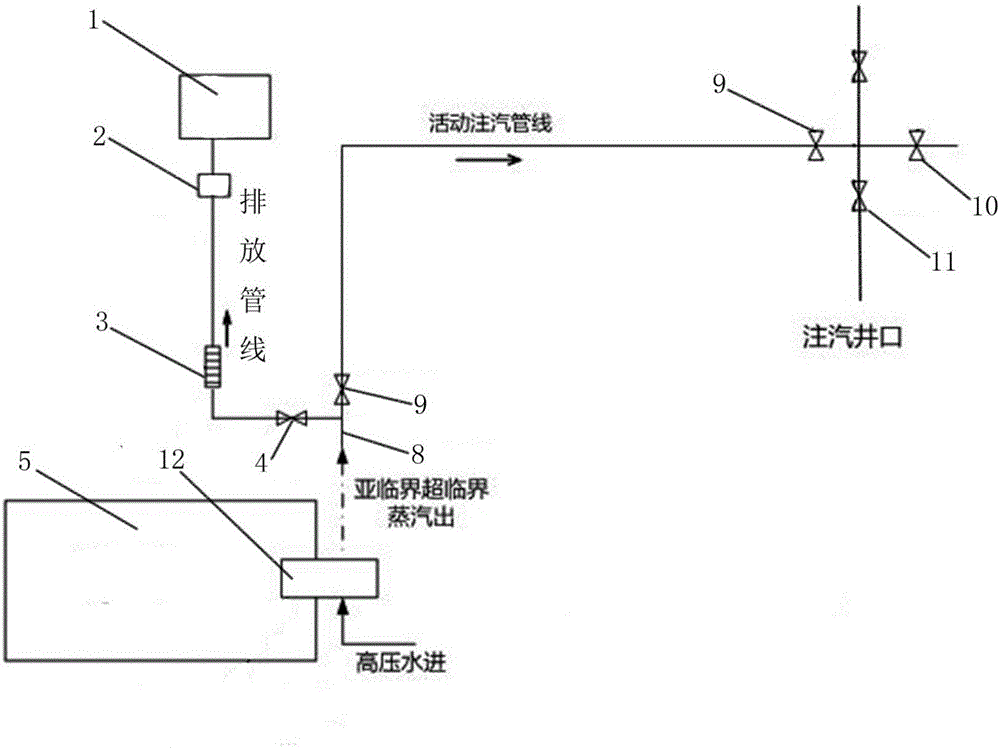

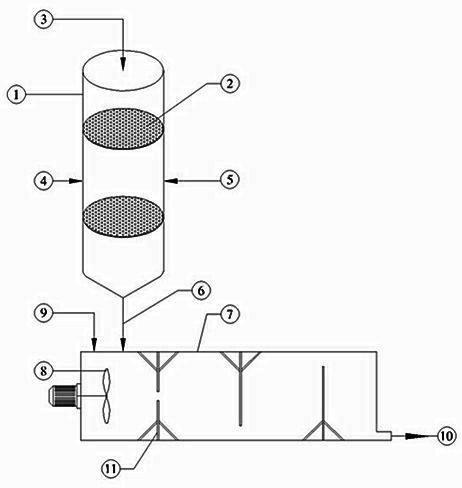

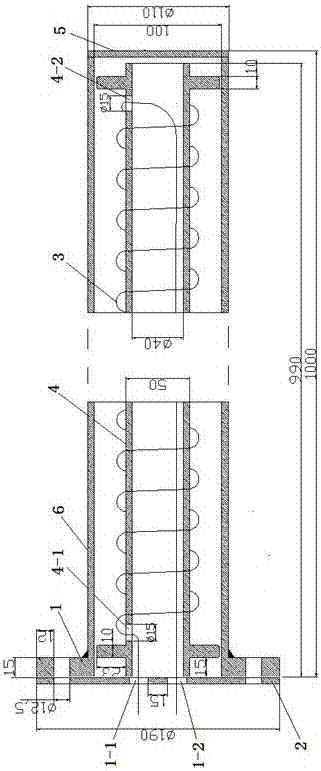

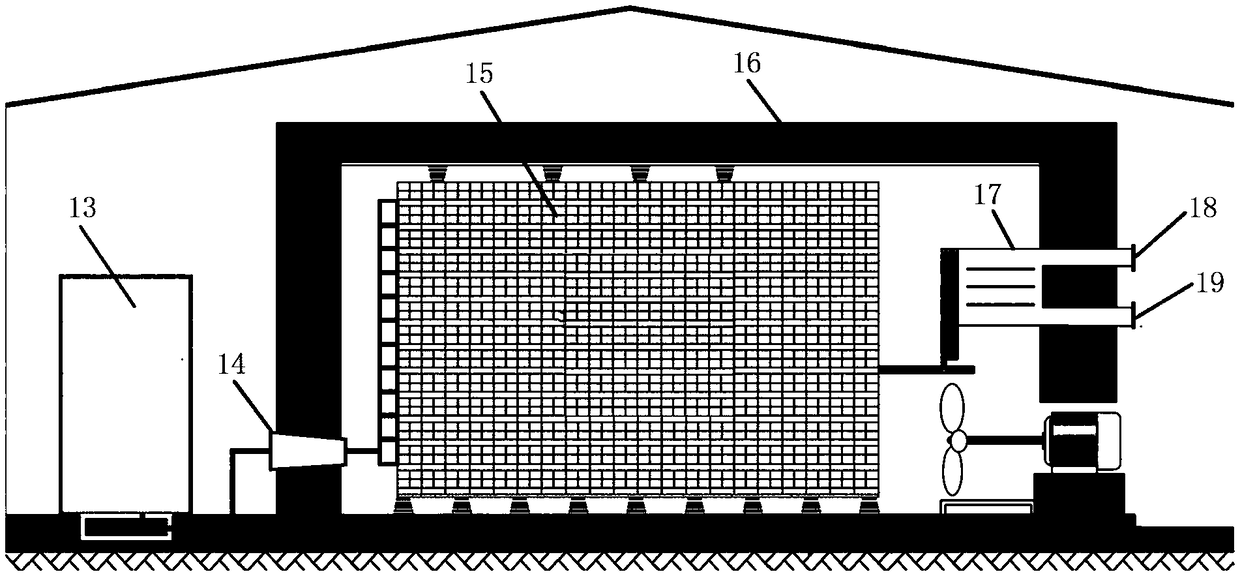

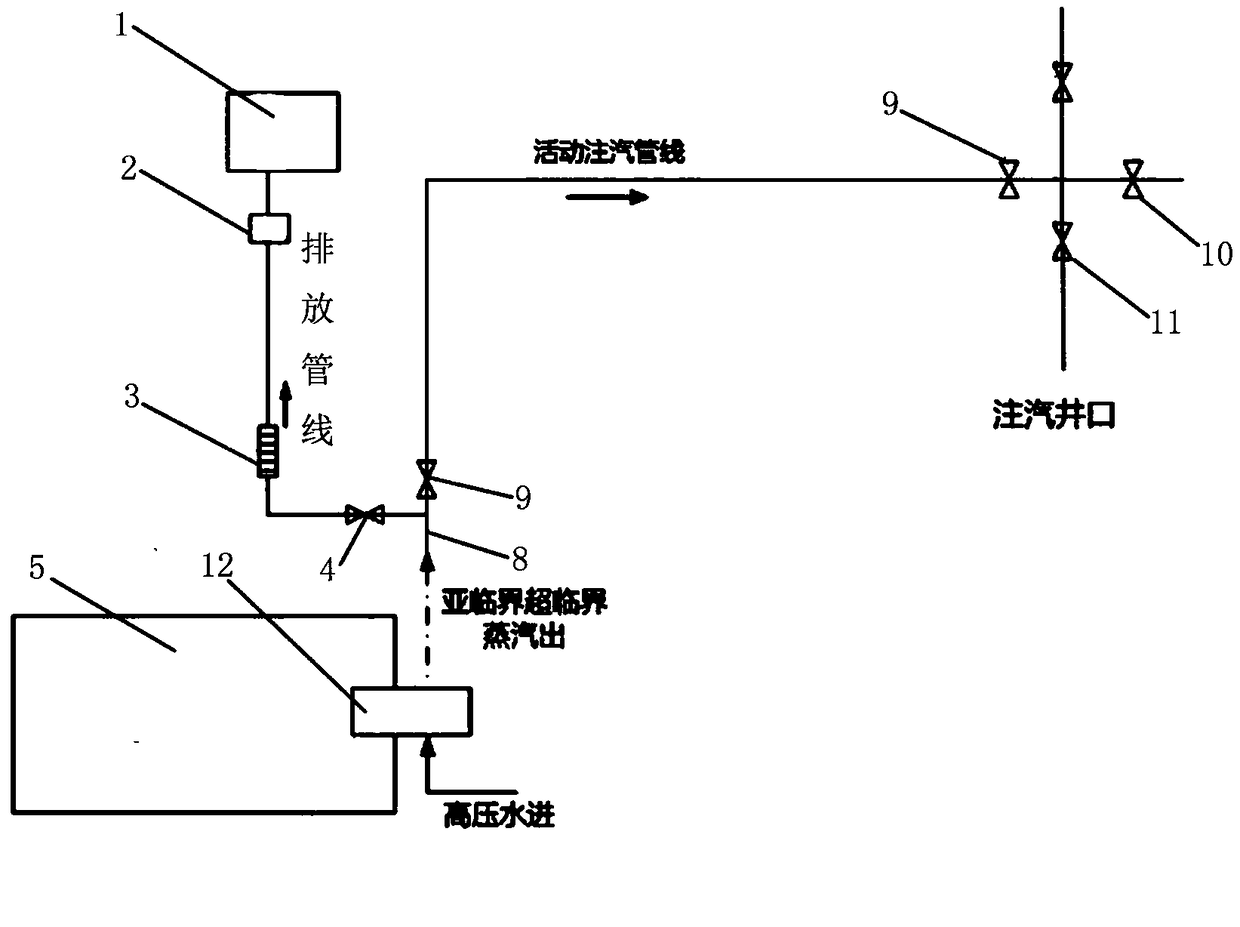

Oil field steam-injection boiler heating system adopting solid thermal-storage electric boiler and two-stage heat exchange

ActiveCN106765004ASolve pollution dischargeSolve the problem of peak and valley electricity balance in the power gridFluid removalElectrode boilersThermal energyElectricity price

The invention provides an oil field steam-injection boiler heating system adopting a solid thermal-storage electric boiler and two-stage heat exchange. The oil field steam-injection boiler heating system comprises a thermal source heating system, a steam injection system and an exhaust pipeline. The thermal source heating system comprises the solid thermal-storage electric boiler and a two-stage heat exchange system. Subcritical and supercritical steam can be generated through the solid thermal-storage electric boiler and the two-stage heat exchange system and injected underground through the steam injection technical system to heat crude oil, and the steam injection and heating processes are conducted on a thickened oil well. Power grid night off-peak electricity with low electricity price can be used and converted into heat energy, and high-temperature heat storage is conducted through the solid thermal-storage electric boiler. Steam injection and heating are conducted on the thickened oil well through high-parameter steam produced by the oil field steam-injection boiler heating system, the problem of combustion emission pollution of an oil field steam injection boiler is solved, peak-valley difference peak regulation can be conducted on a power grid by combining the electric boiler and the energy storage technology, and the best solution scheme facilitating energy conservation, emission reduction and environment protection of the petroleum industry and electricity peak regulation of power plants and the power grid is achieved.

Owner:HEPU TECH DEV BEIJING CO LTD

Novel zirconium composite ceramic material

InactiveCN104150865AAvoid pollutionSmall coefficient of thermal expansionClaywaresComposite ceramicAcrylic resin

The invention discloses a novel zirconium composite ceramic material which is characterized by being prepared from the following substances in parts by weight: 10-20 parts of titanium corundum, 35-50 parts of Macang soil, 4-8 parts of aluminum nitride, 15-31 parts of chinastone, 11-15 parts of maize powder, 3.2-9 parts of ferric oxide, 5-17 parts of acrylic resin, 5-13 parts of silicon nitride, 35-48 parts of ox bones, 11-19 parts of magnesium oxide, 3-9 parts of chromic oxide, 1.6-5.4 parts of boron nitride, 15-40 parts of zirconium dioxide and 5-11 parts of aluminum oxide. The material disclosed by the invention is small in coefficient of thermal expansion, low in cost, resource-saving and high in refractoriness, thermal shock stability resistance and oxidation resistance, and solves the problems of pollution of waste residues and emission of pollution of industrial waste residues. Nitrogen and oxygen in air are fully utilized as fuels, so that the energy sources are saved, thereby achieving the effects on saving energy and reducing emission to a great extent.

Owner:QINGDAO XIANGHAI ELECTRONICS

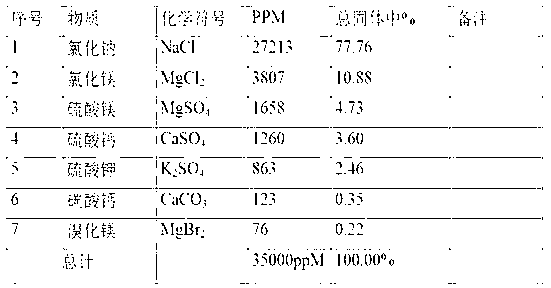

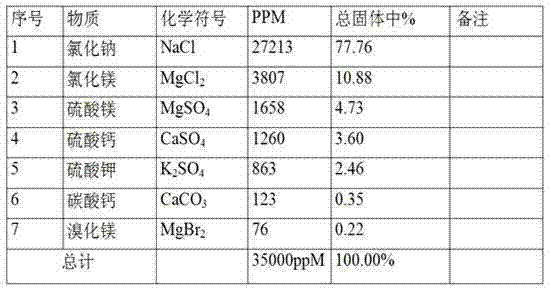

Method and equipment for producing plant nitrogen fertilizer nutrient solution by taking seawater as raw materials

InactiveCN102701822AReduced desalination production costsSolve pollution dischargeFertilizer mixturesNutrient solutionAmmonium nitrate

The invention discloses a method and equipment for producing plant nitrogen fertilizer nutrient solution by taking seawater as a raw material, which achieves zero emission and is favorable for the environment. The method is characterized by comprising the following steps: a, taking seawater as the raw material, adding ammonia gas and carbon dioxide gas in the seawater, and enabling slat compounds in the seawater to be fully mixed with the ammonia gas and the carbon dioxide gas to generate ammonia-carbon compound water, wherein the adding amount of the ammonia gas is 45 to 55 percent of the mass of the salt compound in the seawater, and the adding amount of the carbon dioxide gas is 70 to 75 percent of the mass of the salt compound in the seawater; and b, adding ammonium nitrate in the ammonia-carbon compound water and enabling ammonium nitrate and the ammonia-carbon compound water to be fully mixed, wherein the adding amount of ammonium nitrate is 56 to 65 percent of the mass of the salt compound in the seawater, so as to generate the nitrogen fertilizer nutrient solution.

Owner:葛文宇

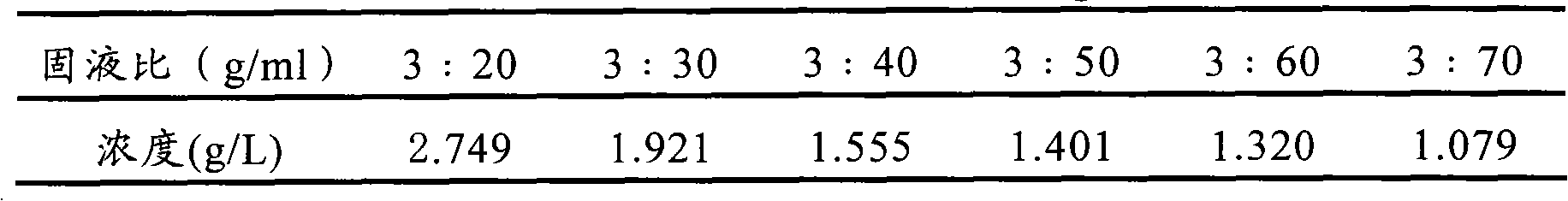

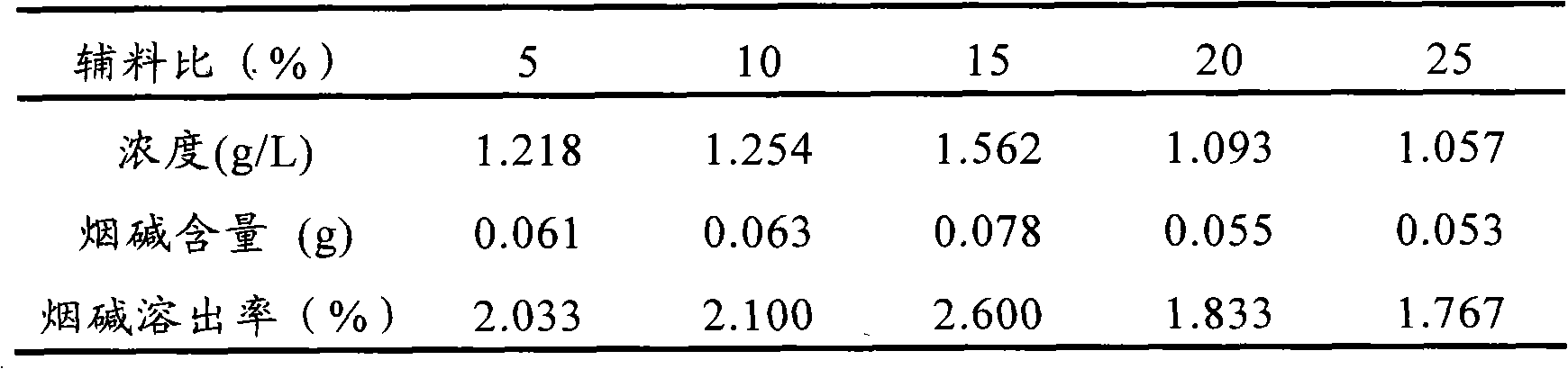

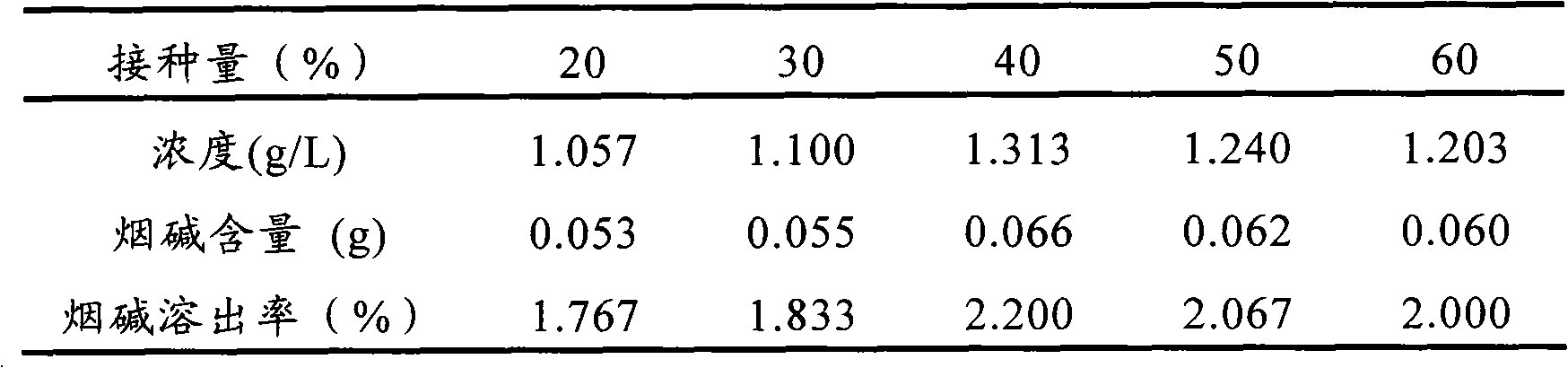

Microbial treatment technology for extracting nicotine

The invention discloses a microbial treatment technology for extracting nicotine, which comprises the following steps: (1) pretreatment of tobacco leaves; (2) cultivation of a microbial strain; (3) fermentation of the tobacco leaves; and (4) extraction of the nicotine. The microbial treatment technology adopts the compound microbial treatment for extracting the nicotine, degrades and damages cellulose, hemicellulose and other plant tissues in tobacco after the microwave treatment through white-rot fungus, pachysolen tannophilus and other microbes, effectively releases the nicotine attached onthe tissue structure and improves the dissolution rate and the extraction rate of the nicotine; and the microbial treatment technology can also effectively degrade organic acid, proteins and the likein the tobacco, reduce the emulsification phenomenon during the extraction process of the nicotine and simultaneously reduce the using amount of an organic solvent. The method has the advantages of high extraction rate of the nicotine, a small using amount of the organic solvent, high recovery rate and ability of effectively realizing the reduction of the discarded tobacco and the resource recycling of the tobacco.

Owner:CHONGQING TECH & BUSINESS UNIV

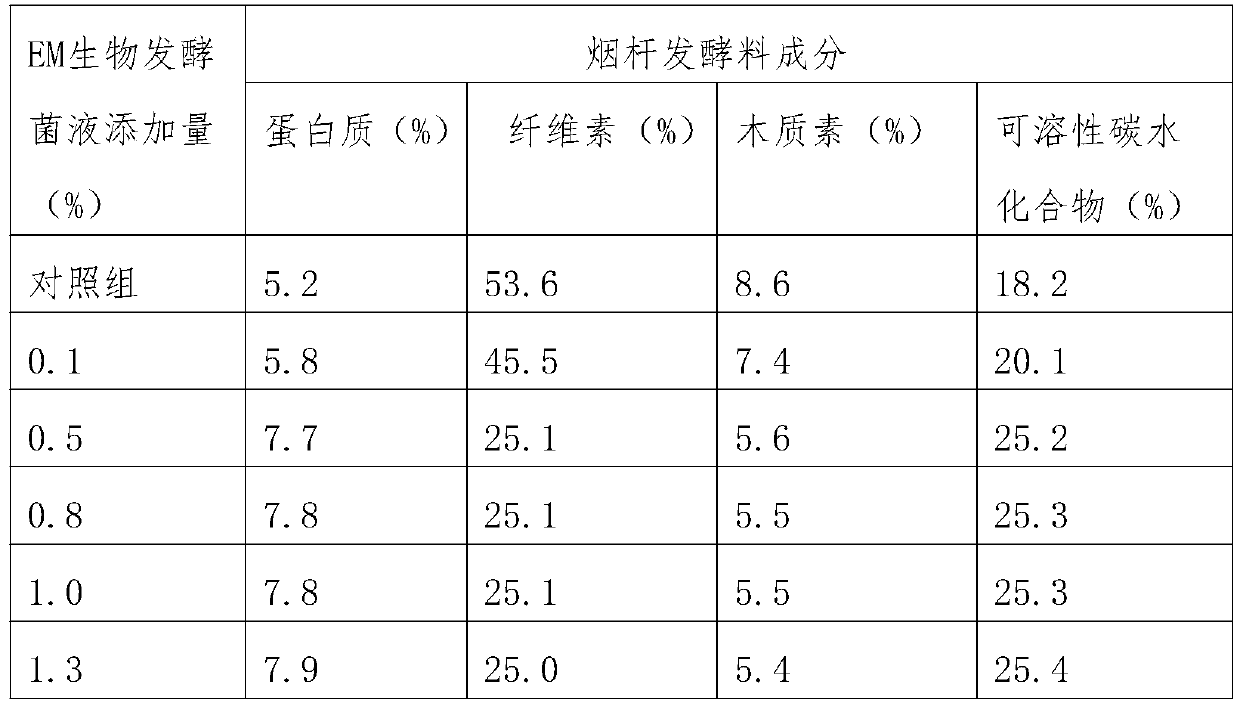

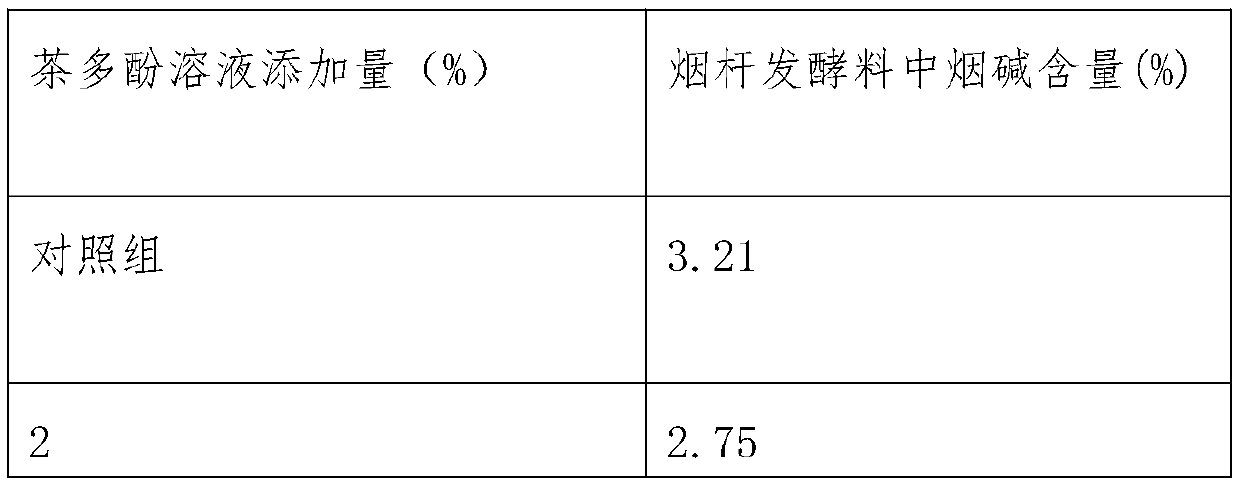

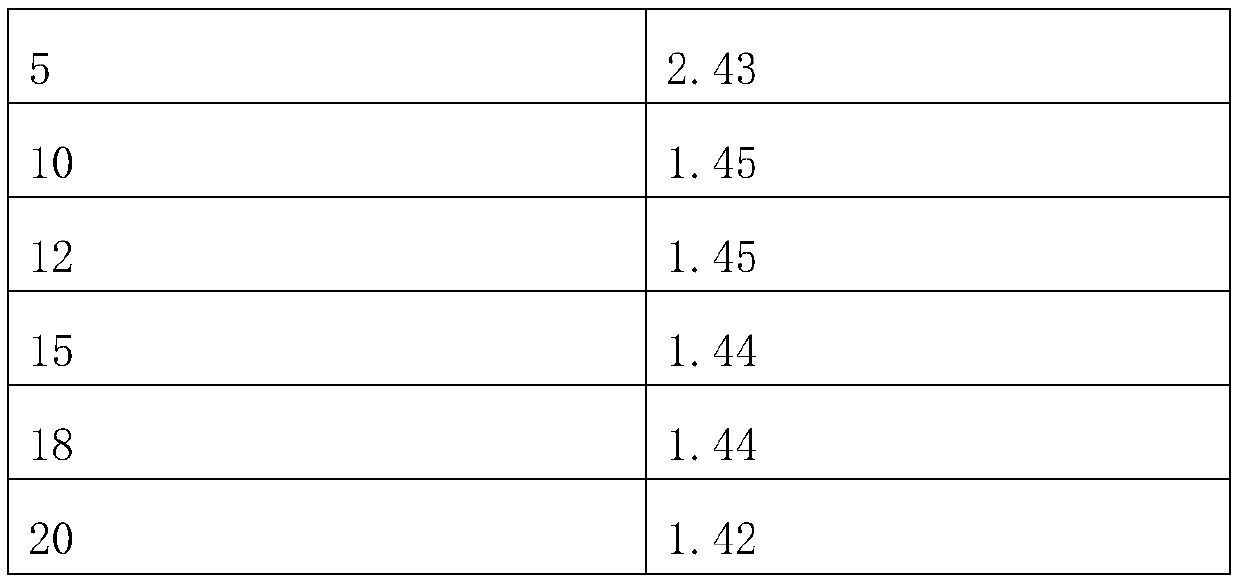

Method for preparing oil-tea mushroom culture medium from tobacco stems and application

InactiveCN110192495ASolve pollution dischargeRealize resource utilizationCultivating equipmentsMushroom cultivationCamellia oleiferaPhenolic content in tea

The invention belongs to the technical field of edible fungus culture, and particularly discloses a method for preparing an oil-tea mushroom culture medium from tobacco stems and application. The method includes the steps of airing and pulverizing the tobacco stems, evenly mixing the tobacco stems with an EM biological fermentation bacteria solution and a tea polyphenol solution to be piled and fermented into a tobacco stem fermentation material, and preparing the culture medium from, by weight, 30-50% of cottonseed hull, 15-25% of wheat bran, 15-35% of the tobacco stem fermentation material,5-15% of bagasse, 1-5% of soybean meal, 3-8% of corn flour and 1-5% of gypsum. The culture medium is prepared into bars, tree fungi are inoculated, and after hypha is cultured, mushrooms are moved outof a greenhouse. Compared with a traditional wood dust culture medium, the prepared culture medium for culturing the oil-tea mushrooms has the advantages that the hypha culture time is shortened by 15 days, the whole hypha is whiter and thicker, the mushroom output time is more concentrated, the tide turning time can be shortened by 4-5 days at most, the sundry fungus contamination rate is reduced by 5-8%, the raw material cost is saved by 15-20%, the biological conversion rate is increased by 20-21%, the average yield is increased by 12-13%, and the overall yield is more stable.

Owner:贵州省贵福菌业发展有限公司 +1

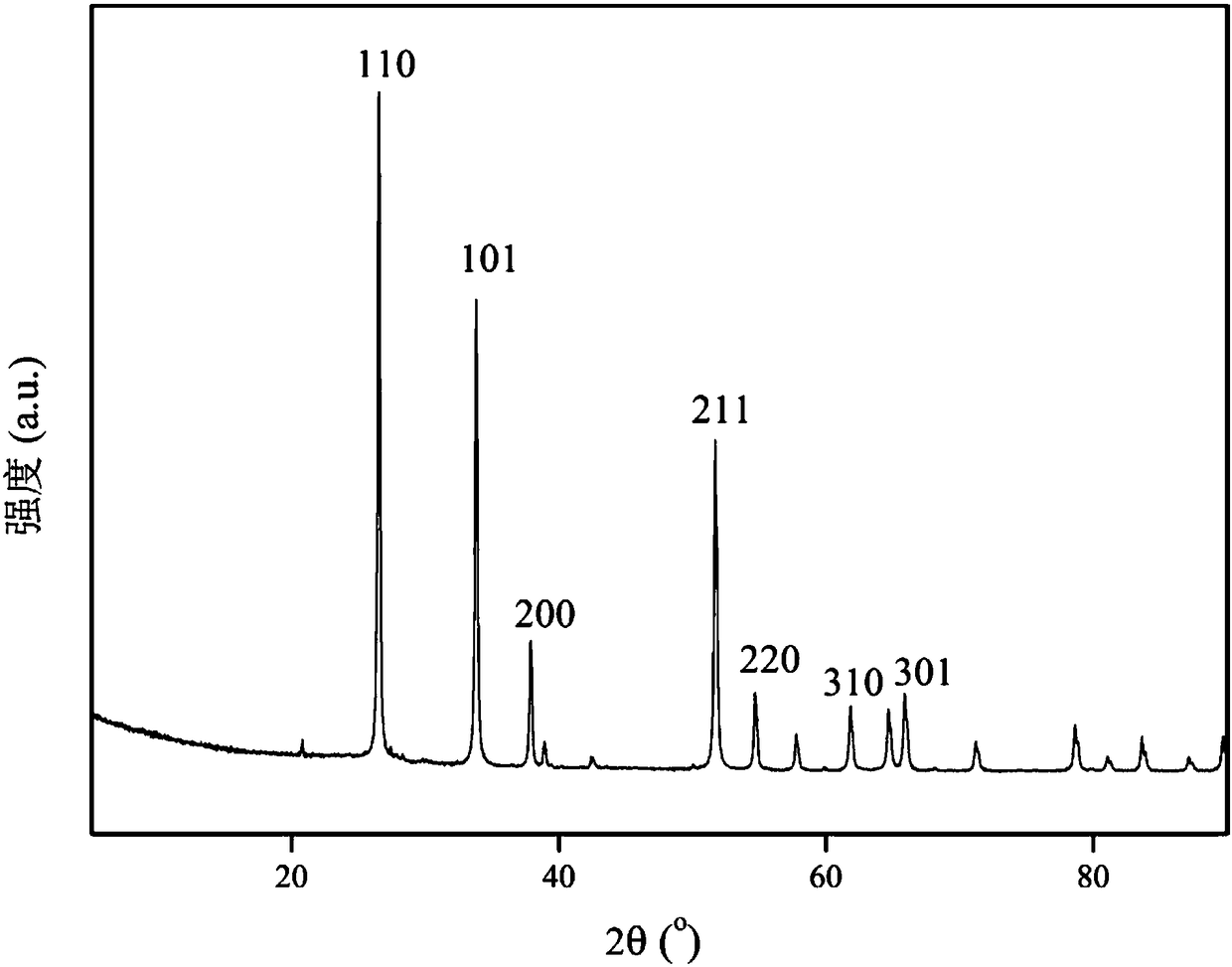

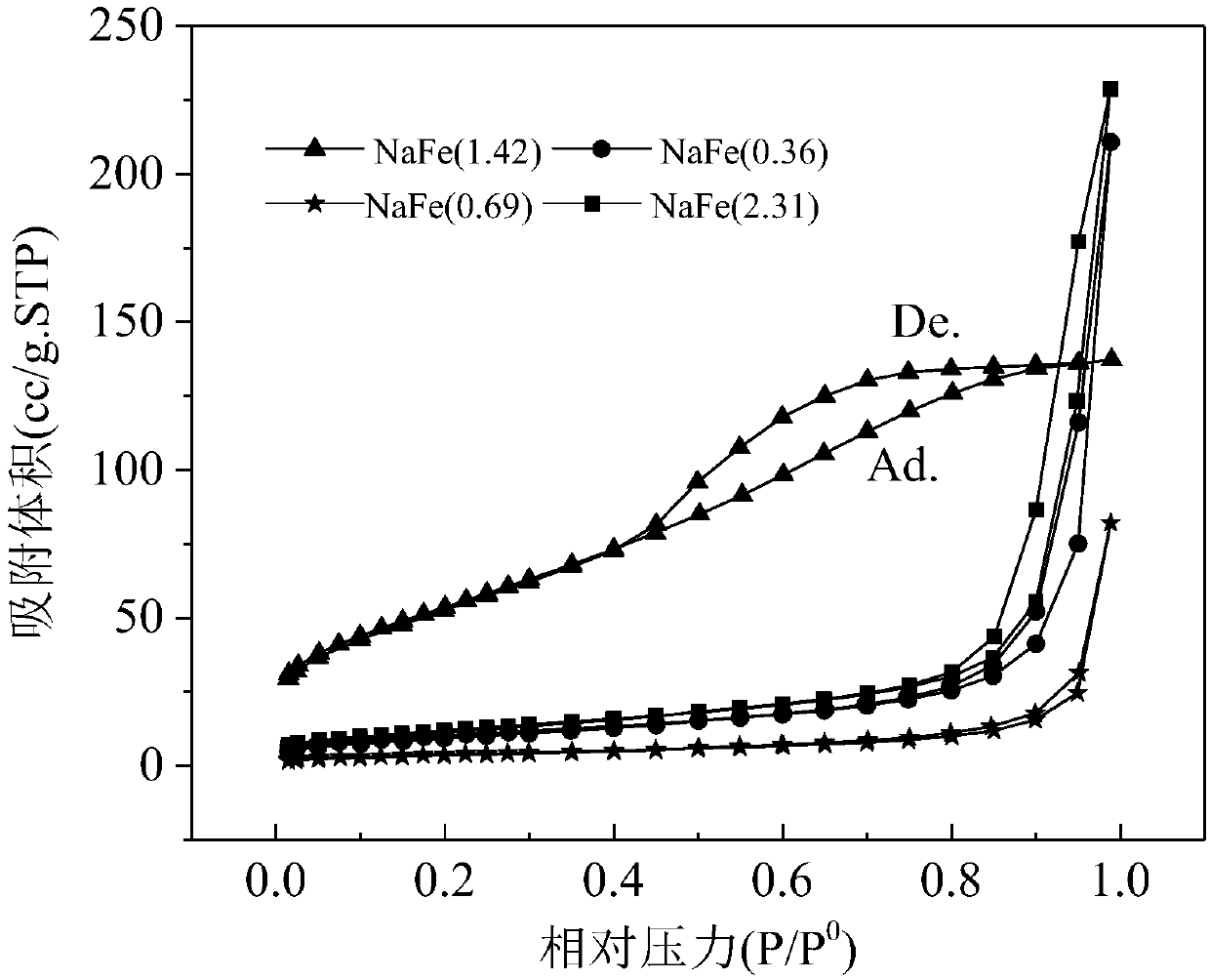

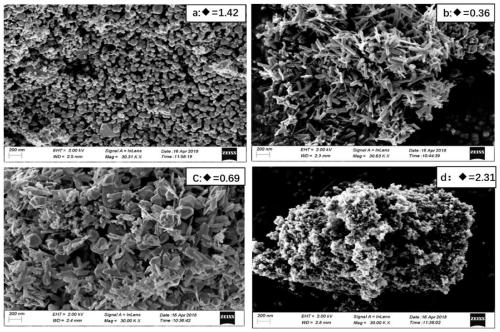

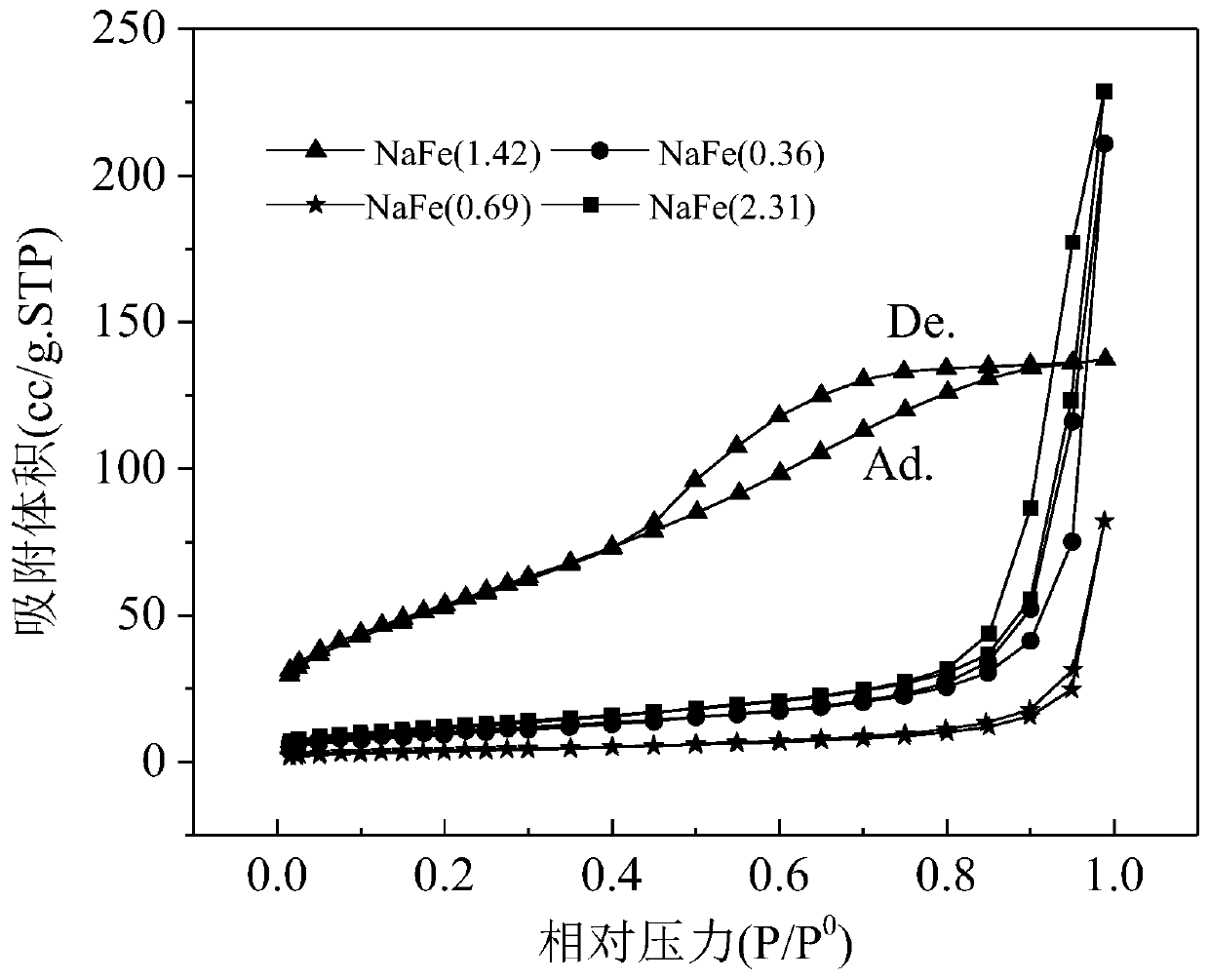

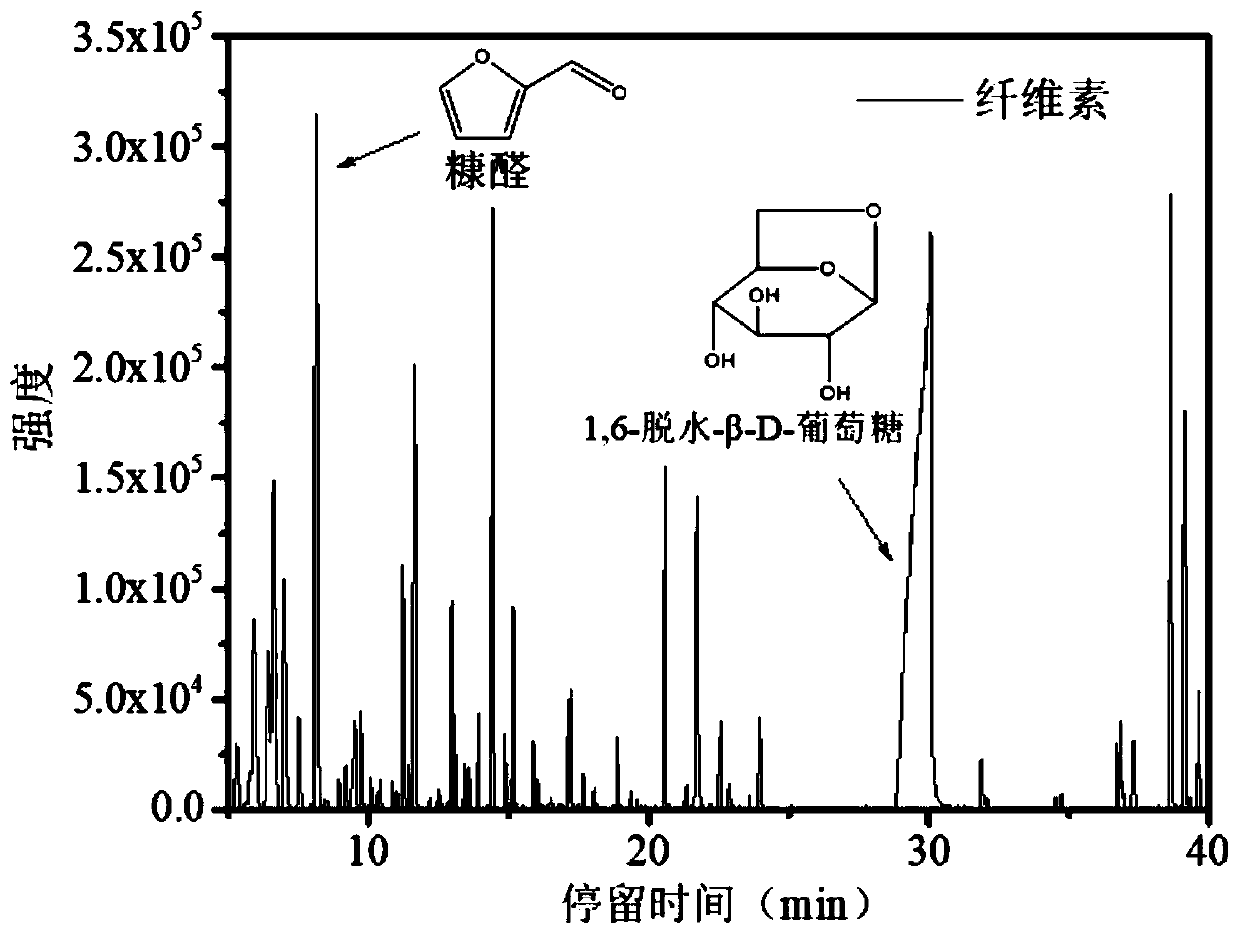

Nanometer Na/Fe composite type solid acid catalyst and preparation method and application thereof

ActiveCN109621964AIncrease the active siteExcellent process parametersOrganic chemistryCatalyst activation/preparationNano catalystSolid acid

The invention belongs to the technical field of biomass utilization, and particularly discloses a nanometer Na / Fe composite type solid acid catalyst and a preparation method and application thereof. The preparation method of the catalyst comprises the following steps that ferrous chloride and ferric chloride are mixed to be uniform under the action of hydrochloric acid according to the certain ratio, then, sodium hydroxide is dropwise added, and the nanometer Na / Fe composite type solid acid catalyst is prepared through a forward sedimentation method. Biomass and the prepared nanometer catalystare mixed according to the certain ratio, pyrolysis is performed under the inert atmosphere, and the high-selectivity furfural product can be obtained. The catalyst is simple in preparation process,low in cost, high in selectivity, capable of solving the problems that in the prior art, furfural selectivity is low and few by-products are produced, and capable of achieving biomass directional conversion and high-value utilization.

Owner:HUAZHONG UNIV OF SCI & TECH

Alcohol liquid fuel

The invention discloses an alcohol liquid fuel, which is mainly synthesized from 45-55 parts of methanol, 15-23 parts of naphtha, 2-6 parts of methylal, 3-7 parts of petroleum ether, 8-15 parts of methyl tert-butyl ether, 0.5-1 part of Malin, and 5-10 parts of an assistant by a specific synthetic method. Through years of research and practice, the technology systematically solves the problems of methanol blending ratio, instant solubility, cold starting, long-term storage stability of finished product, production process continuous synthesis and the like. Also a variety of vehicles are adoptedfor long-distance driving test with the alcohol liquid fuel and achieve satisfactory effects, the trial result indicates that: the alcohol liquid fuel has the advantages of fast start, good power, enough momentum, no carbon deposit, no smoke, and improves the vehicle condition. Therefore, the technology can be applied to large-scale industrial production.

Owner:国通达新能源有限公司

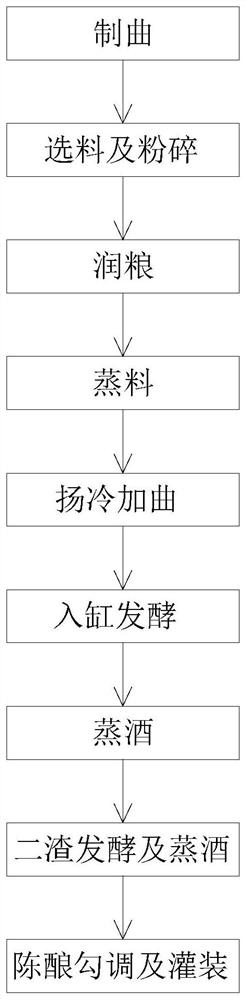

White spirit production process

The invention discloses a white spirit production process and relates to the technical field of food processing. The process mainly comprises the following steps of koji making, material selection and crushing, grain moistening, material steaming, cooling and koji addition, fermentation in a jar, wine steaming, secondary residue fermentation and wine steaming, and aging, blending and filling. Straws discharged from a koji room are crushed into fine powder by using a crusher, and the fine powder and crushed koji-making raw materials are pressed into koji blocks according to an addition ratio of 5%. Compared with the fermentation without straw powder, the fermentation of the koji blocks is fast in temperature rise and sufficient in fragrance, and the growth conditions of harmful bacteria in the koji blocks are inhibited and controlled, so that the quality of koji is improved. The koji blocks are firstly subjected to coarse crushing and then subjected to fine crushing, the crushing size of the koji blocks for large-residue fermentation is controlled to be 1-1.5 mm in particle size, the crushing size of the koji blocks for secondary residue fermentation is controlled to be 0.8-1.2 mm in particle size, the crushing fineness of yeast for making hard liquor can influence the fermentation temperature rise speed, crushing is relatively coarse, and temperature rise is relatively slow during fermentation, so that low-temperature slow fermentation is facilitated; and particles are relatively fine, and the fermentation temperature rise is relatively fast.

Owner:颍上双集双泉酒业有限公司

Method and equipment for producing plant nitrogen fertilizer nutrient solution by taking seawater as raw materials

InactiveCN102701822BReduced desalination production costsSolve pollution dischargeFertilizer mixturesNutrient solutionAmmonium nitrate

The invention discloses a method and equipment for producing plant nitrogen fertilizer nutrient solution by taking seawater as a raw material, which achieves zero emission and is favorable for the environment. The method is characterized by comprising the following steps: a, taking seawater as the raw material, adding ammonia gas and carbon dioxide gas in the seawater, and enabling slat compounds in the seawater to be fully mixed with the ammonia gas and the carbon dioxide gas to generate ammonia-carbon compound water, wherein the adding amount of the ammonia gas is 45 to 55 percent of the mass of the salt compound in the seawater, and the adding amount of the carbon dioxide gas is 70 to 75 percent of the mass of the salt compound in the seawater; and b, adding ammonium nitrate in the ammonia-carbon compound water and enabling ammonium nitrate and the ammonia-carbon compound water to be fully mixed, wherein the adding amount of ammonium nitrate is 56 to 65 percent of the mass of the salt compound in the seawater, so as to generate the nitrogen fertilizer nutrient solution.

Owner:葛文宇

Method of recovering byproduct generated in glass CVD (chemical vapor deposition) filming technology and application of method

InactiveCN108675340ALow costSolve pollution dischargeMaterial nanotechnologyDispersed particle separationExhaust gasAir suspension

The invention relates to the field of chemistry, in particular to a method of recovering a byproduct generated by a glass CVD (chemical vapor deposition) filming technology and an application of the method. The method comprises the following steps of: S1: drying the byproduct generated by the glass CVD technology in a drier to form dry powder, S2: adding the dry powder obtained in S1 into a vibration sizer for vibration separation to form a separation mixture, and S3: adding the separation mixture obtained in S2 into an air suspension separator for refined separation treatment to form nanoscale tin dioxide and micron-sized sodium bicarbonate. The method is simple in step and low in cost; nanoscale tin dioxide recovered by the method can serve as a raw material of automobile tail gas purifying agent; materials can be recycled; the cost of the raw material of the automobile tail gas purifying agent is lowered; the method can be used for the field of automobile environmental protection and solves the pollution emission problem of a glass enterprise at the same time.

Owner:上海再益新材料有限公司

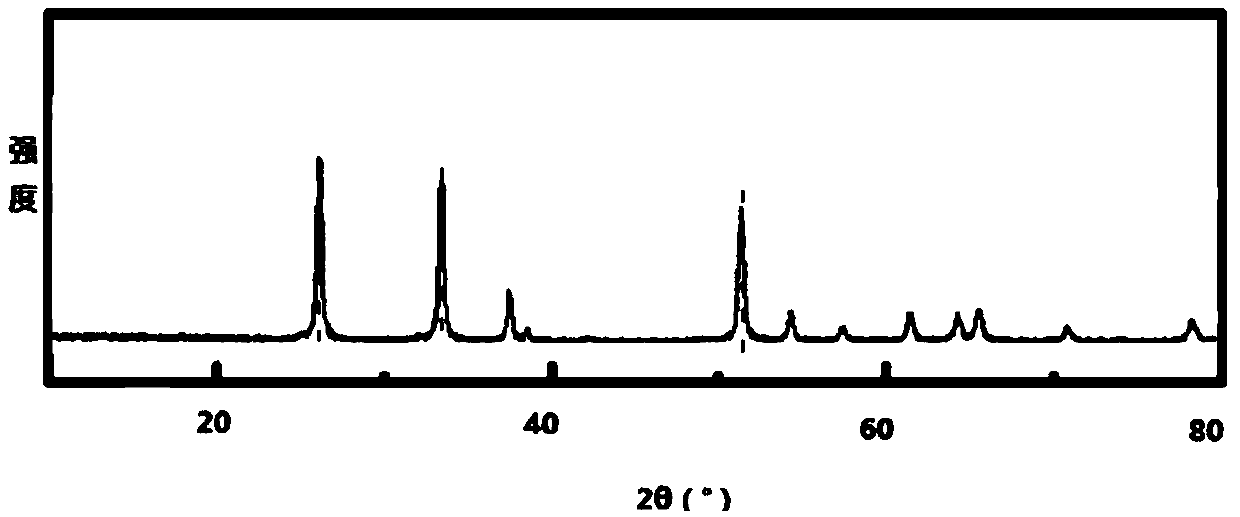

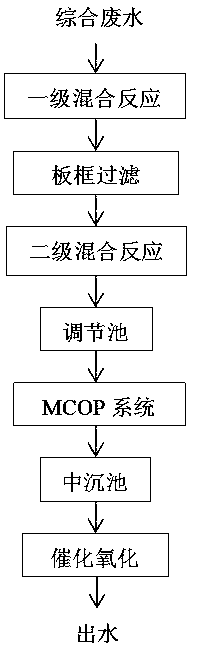

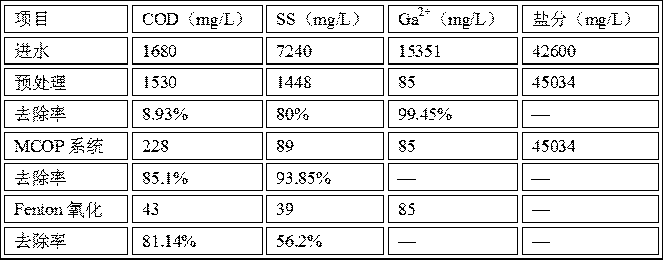

High-temperature propylene chlorination process epichlorohydrin production waste water integrated treatment process

InactiveCN108275843AAchieve degradationPromote enrichmentTreatment using aerobic processesTreatment involving filtrationElectrolysisPollution

The invention discloses a high-temperature propylene chlorination process epichlorohydrin production waste water integrated treatment process, which belongs to the technical field of environmental protection. Each high-temperature propylene chlorination process production enterprise is equipped with an electrolytic edible saline solution section, a majority of enterprises adopt the edible saline solution by exploiting underground brine, the brine contains a certain amount of Na2SO4 which influences the electrolysis of the edible saline solution, so that the Na2SO4 needs to be separated beforeelectrolysis of the edible saline solution. A great amount of CaCl2 is generated in a cyclization phase of the high-temperature propylene chlorination process for producing the epichlorohydrin and enters waste water, and the treated CaCl2-containing waste water cannot be directly discharged. According to the above situation, Na2SO4 is adopted to react with CaCl2 to generate CaSO4, i.e., gypsum, and after the separation, the gypsum can be used as an auxiliary material of a cement factory; and after the reaction, the waste water containing a great amount of NaCl and COD enters an MCOP (modifiedcontact oxidation process) system to perform the biochemical reaction, the water produced in the reaction is oxidized at a high level to further remove COD, so that the COD of the discharged water isless than or equal to 60 mg / L, the waste water containing a great amount of NaCl can be used as a dilute saline solution for exploiting saline brine. By adopting the process, not only is the problem that the utilization rate of the Na2SO4 is low solved, but also the pollution emission problem of the CaCl2 can be solved, a purpose of treating the waste by using waste can be achieved, and the industrial policy of the national resource comprehensive utilization can be satisfied.

Owner:河南君和环保科技有限公司

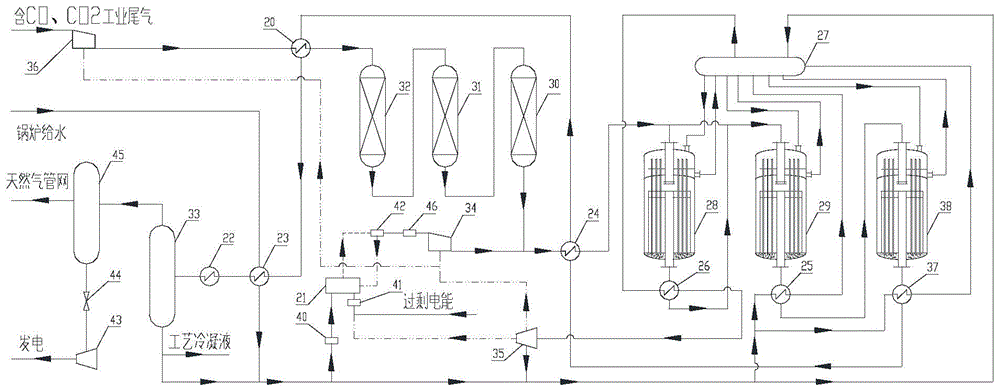

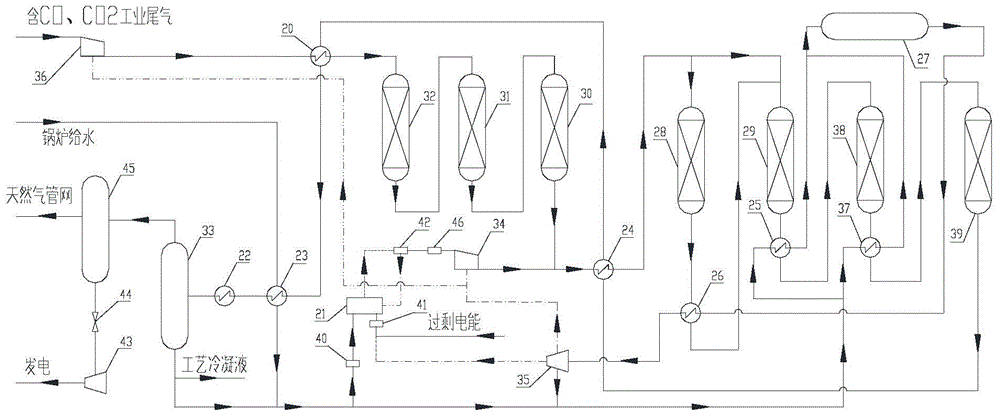

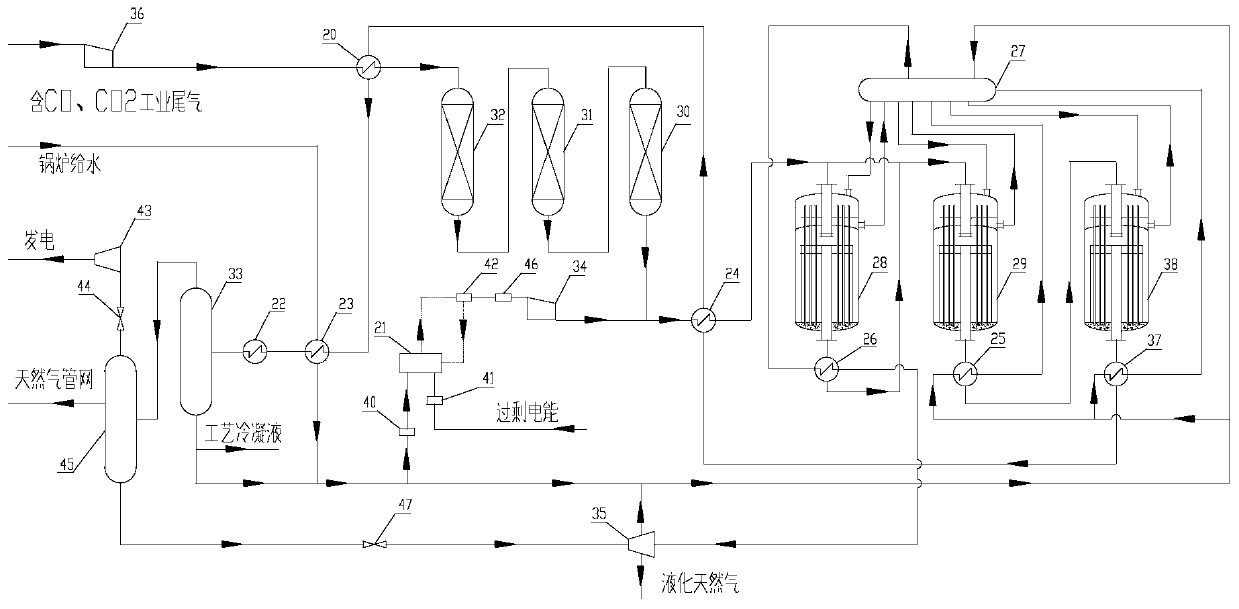

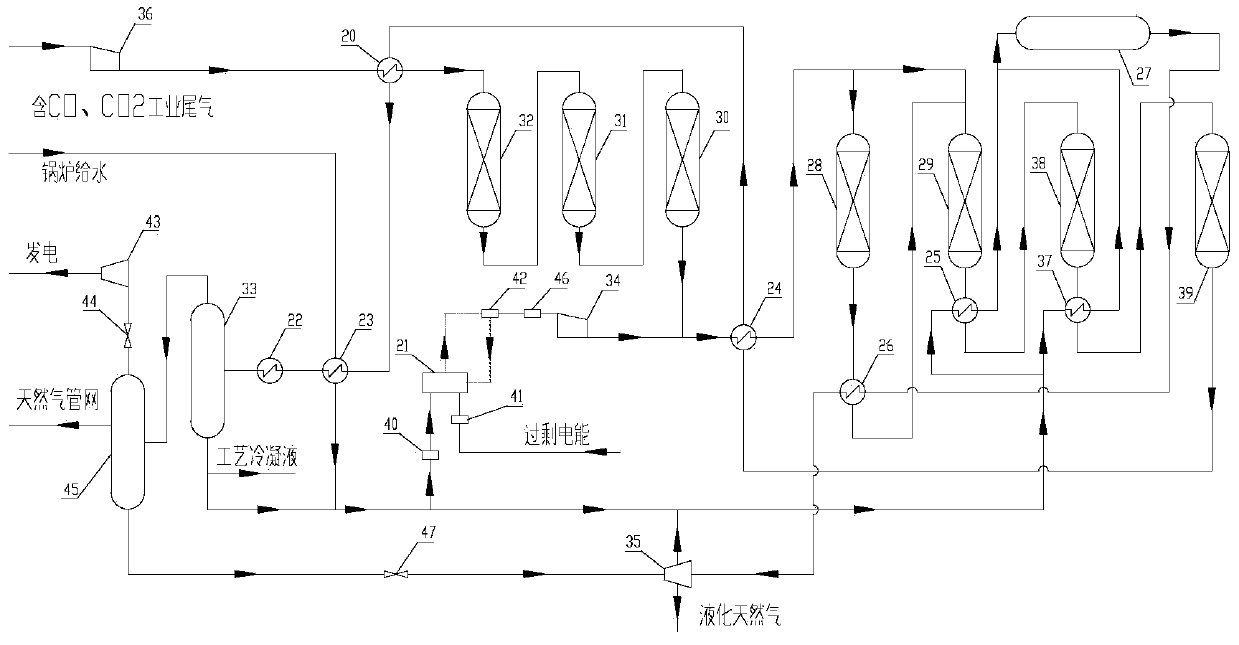

System and process for storing and releasing electric energy

ActiveCN106160242ASolving Massive Storage ProblemsProduct DiversityElectrical storage systemAutomotive engineeringHeating system

The invention discloses a system and a process for storing and releasing electric energy based on a methanation reaction. The system and the process each comprise a carbon-oxygen-containing purification system, a gas generation system, a methanation system, a vapor heating system of the methanation system, a product separation system, a product storage system and a gas power generation system. Compared with the prior art, the system and the process provided by the invention can realize the purposes of performing peak regulation of the existing power grid and improving electric energy utilization efficiency through storing excess electric energy in the form of a substitute natural gas, and generating electric energy by a gas turbine power generation system through utilizing the substitute natural gas when the power utilization peak comes.

Owner:SINOPEC ENG +1

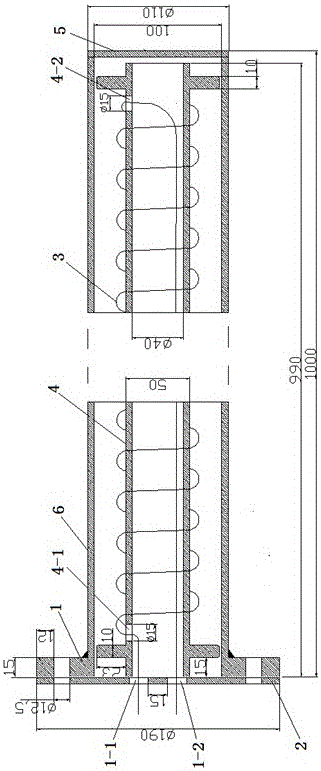

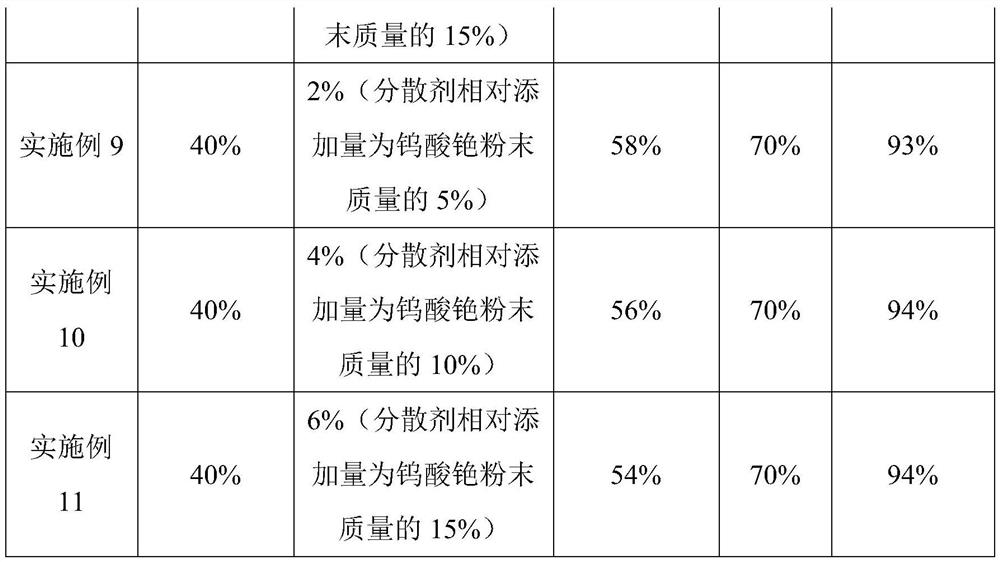

Super-audio electromagnetic bar

ActiveCN105889885AFast heatingExtended service lifeSteam generation heating methodsCoil arrangementsElectric heatingElectricity

The invention relates to a super-audio electromagnetic bar. A bottom plate is welded at one end of a stainless steel heating tube, and a flange is welded outside an opening in the other end of the stainless steel heating tube; a coil winds around a ceramic tube by multiple circles at intervals; the ceramic tube is arranged inside the stainless steel heating tube; a joint at one end of the coil enters the ceramic tube via an upper coil outgoing hole in the ceramic tube and extends out of a hole I in a flange plate connected with the flange; and a joint at the other end of the coil enters the ceramic tube via a lower coil outgoing hole in the ceramic tube and extends out of a hole II in the flange plate connected with the flange. Problems of low electricity-heat transformation rates, disability of stepless regulation of output power, low maximum output power, disability of parching, short service life, possibility of production of scale and the like, which are not solved so far, of domestic like products are better solved. The electricity-heat transformation rate is higher than that of an external coil, electromagnetic wave shielding is realized, radiation and interference are avoided, water and electricity are separated, potential safety hazards are avoided, and the electromagnetic bar is simple in structure and can be widely applied to various electric heating devices.

Owner:TIANJIN SAIJIN ENERGY SAVING SCI & TECH CO LTD

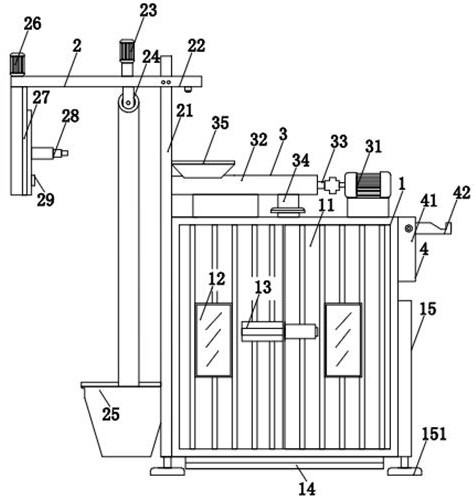

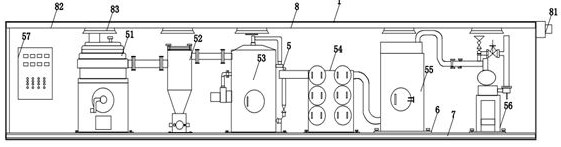

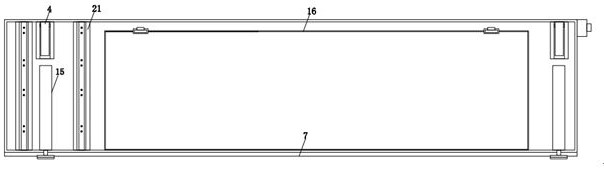

Movable comprehensive resourceful treatment device for biological organic wastes

PendingCN112322353ARapid deploymentEasy to moveCombination devicesGas treatmentEnvironmental engineeringRefuse Disposals

The invention provides a movable biological organic waste comprehensive resourceful treatment device for biological organic wastes. The device comprises a container, a feeding mechanism used for lifting and feeding organic waste is installed on one side of the container, and a feeding mechanism matched with the feeding mechanism for feeding is installed at the top of the container. Connecting mechanisms used for connecting and fixing a plurality of box bodies are installed on the two sides of the container correspondingly, a treatment mechanism used for comprehensive resourceful treatment of organic waste is installed in the container, and an air cooling mechanism used for in-box heat dissipation is further installed at the top end of the interior of the container. The treatment device cancomprehensively treat resources of organic waste, the electric hydraulic jacks arranged on the two sides of the container can support the container, rapid loading and unloading of the container are facilitated, meanwhile, the treatment device is made into a container type, the treatment device can be conveniently moved and transported, and the practicability is high. The system can also be used for household garbage treatment in small and medium-sized communities.

Owner:国千环境科技(昆山)有限公司

High-corrosion-resistance composite ceramic material

The invention discloses a high-corrosion-resistance composite ceramic material which is characterized by comprising the following components in parts by weight: 25-45 parts of zirconite, 31-55 parts of titanium corundum, 10-23 parts of zirconium silicate, 21-47 parts of Cangma soil, 5.5-13.7 parts of boron nitride, 1-10 parts of silicon dioxide, 5-19 parts of titanium mineral, 5-11 parts of borax, 1-8 parts of zirconium dioxide, 3-9 parts of manganese oxide, 1-4 parts of chrome oxide, 15-49 parts of magnesite, 0.5-3.7 parts of magnesium oxide, 11-28 parts of apatite, 5-27 parts of dolomite and 1-3 parts of alumina. The high-corrosion-resistance composite ceramic material has the advantages of small thermal expansion coefficient, low cost, high fire resistance, high thermal shock stability and high oxidation resistance, solves the waste residue pollution, saves the resources, solves the problem of industrial residue pollution discharge, thoroughly utilizes nitrogen and oxygen in air as fuels, saves the energy sources, and has the effects of energy saving and emission reduction.

Owner:QINGDAO XIANGHAI ELECTRONICS

A system and process for storing and releasing electrical energy

ActiveCN106160243BSolving Massive Storage ProblemsReduce processingElectrical storage systemEnergy storageMethanationSubstitute natural gas

The invention discloses a system and a process for storing and releasing electric energy on the basis of a methanation reaction. The system and the process both comprise a carbon oxide compound purifying system, a gas generating system, a methanation system, a steam heating system of the methanation system, a steam turbine system, a product separation system, a product storage system and a gas power generation system. Compared with the prior art, through the system and the process, the excess electric energy is stored in the form of substitute natural gas, so that when the peak time of electricity consumption arrives, the substitute natural gas produces electric energy through a gas turbine power generation system, and the purposes of regulating peak load of an existing power grid and improving the efficiency of power consumption are fulfilled.

Owner:SINOPEC ENG +1

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201BAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

Preparation method of high-calorific-value nonpolar bio-oil/gasoline homogeneous fuel oil

InactiveCN103571527BIncrease profitSolve pollution dischargeMolecular sieve catalystsTreatment with plural serial refining stagesActivated carbonElectrical polarity

The invention discloses a preparation method of high-calorific-value nonpolar bio-oil / gasoline homogeneous fuel oil. The method aims at increasing a calorific value of bio-oil. The method comprises the steps that primary bio-oil is subjected to catalytic cracking and deoxidized by an NiCoMo / HZSM-5 catalyst; the deoxidized bio-oil is dehydrated and decolorized by CaCl2 and activated carbon; polar components of the bio-oil are separated by a silica gel column chromatography; nonpolar bio-oil is obtained; finally the nonpolar bio-oil can be mixed with gasoline in any proportion by mechanical stirring, without adding any emulsifier. The method solves the problem of lower calorific value caused by oxygen and water containing in the primary bio-oil, overcomes the defects of great primary bio-oil polarity and gasoline insolubility, and is high in primary bio-oil utilization ratio; the prepared fuel oil is environment-friendly and high in calorific value; the calorific value can reach 46-55MJ / kg. A good solution is provided for high-efficiency utilization of the bio-oil in a gasoline engine.

Owner:HEFEI UNIV OF TECH

A kind of beneficiation method of low-grade zinc-containing raw ore

ActiveCN110972482BRealize economic and environmental protection utilizationAchieve synthesisZinc oxides/hydroxidesProcess efficiency improvementZincateMining engineering

A method for beneficiating low-grade zinc-containing ore, in particular to a method for beneficiating low-grade zinc-containing ore through a calcium zincate synthesis step, the method comprising an extraction step, a decarburization precipitation step, a calcium zincate synthesis step, Dry calcination step.

Owner:CHONGQING DONGQUN TECH CO LTD

A kind of nano na/fe composite solid acid catalyst and its preparation method and application

ActiveCN109621964BIncrease the active siteExcellent process parametersOrganic chemistryCatalyst activation/preparationNano catalystPtru catalyst

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of high-calorific-value nonpolar bio-oil/gasoline homogeneous fuel oil

InactiveCN103571527AIncrease profitSolve pollution dischargeMolecular sieve catalystsTreatment with plural serial refining stagesActivated carbonEnvironmental resistance

The invention discloses a preparation method of high-calorific-value nonpolar bio-oil / gasoline homogeneous fuel oil. The method aims at increasing a calorific value of bio-oil. The method comprises the steps that primary bio-oil is subjected to catalytic cracking and deoxidized by an NiCoMo / HZSM-5 catalyst; the deoxidized bio-oil is dehydrated and decolorized by CaCl2 and activated carbon; polar components of the bio-oil are separated by a silica gel column chromatography; nonpolar bio-oil is obtained; finally the nonpolar bio-oil can be mixed with gasoline in any proportion by mechanical stirring, without adding any emulsifier. The method solves the problem of lower calorific value caused by oxygen and water containing in the primary bio-oil, overcomes the defects of great primary bio-oil polarity and gasoline insolubility, and is high in primary bio-oil utilization ratio; the prepared fuel oil is environment-friendly and high in calorific value; the calorific value can reach 46-55MJ / kg. A good solution is provided for high-efficiency utilization of the bio-oil in a gasoline engine.

Owner:HEFEI UNIV OF TECH

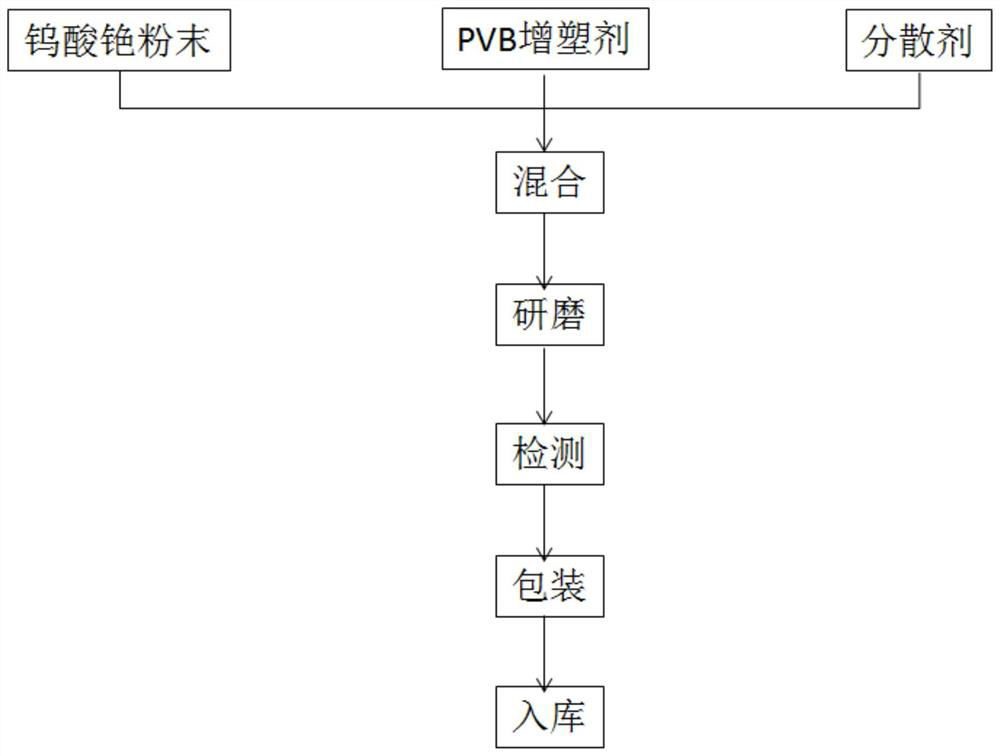

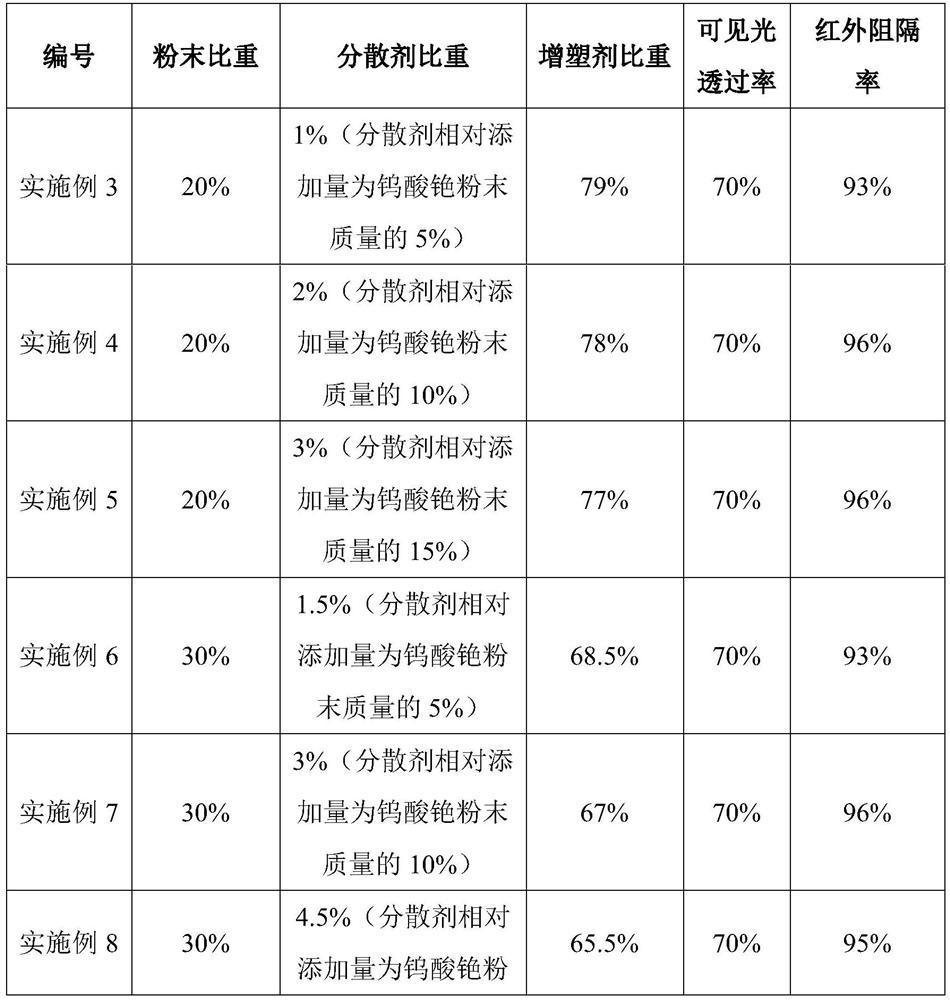

A kind of cesium tungstate slurry for PVB safety glass and preparation method thereof

ActiveCN110616051BSolve pollution dischargeExcellent transparent heat insulation performanceNon-macromolecular adhesive additivesFilm/foil adhesives without carriersOrganic solventTungstate

The embodiment of the present invention provides a cesium tungstate slurry for PVB safety glass and its preparation method. In the slurry, except cesium tungstate powder, it only includes a low content of dispersant and PVB plasticizer. Both the solvent and the PVB plasticizer are refractory reagents, which solve the problem that the current cesium acid slurry is prepared and stored with a volatile organic solvent as a medium, and the problem of large pollution emissions will be generated in the process of making safety glass. Using the embodiment of the present invention provides cesium tungstate slurry for PVB safety glass, the prepared cesium tungstate slurry for PVB safety glass has excellent transparent heat insulation performance, the visible light transmittance reaches 70%, and the infrared rejection rate is higher than 95%. The present invention The preparation method of cesium tungstate slurry for PVB safety glass provided in the embodiment has simple process steps, does not require complicated equipment and harsh production conditions, and is easy to be popularized and applied.

Owner:长沙壹纳光电材料有限公司

A super audio electromagnetic rod

ActiveCN105889885BHigh electrothermal conversion rateIncrease the maximum output powerSteam generation heating methodsCoil arrangementsElectricityMaterials science

The invention relates to a super-audio electromagnetic bar. A bottom plate is welded at one end of a stainless steel heating tube, and a flange is welded outside an opening in the other end of the stainless steel heating tube; a coil winds around a ceramic tube by multiple circles at intervals; the ceramic tube is arranged inside the stainless steel heating tube; a joint at one end of the coil enters the ceramic tube via an upper coil outgoing hole in the ceramic tube and extends out of a hole I in a flange plate connected with the flange; and a joint at the other end of the coil enters the ceramic tube via a lower coil outgoing hole in the ceramic tube and extends out of a hole II in the flange plate connected with the flange. Problems of low electricity-heat transformation rates, disability of stepless regulation of output power, low maximum output power, disability of parching, short service life, possibility of production of scale and the like, which are not solved so far, of domestic like products are better solved. The electricity-heat transformation rate is higher than that of an external coil, electromagnetic wave shielding is realized, radiation and interference are avoided, water and electricity are separated, potential safety hazards are avoided, and the electromagnetic bar is simple in structure and can be widely applied to various electric heating devices.

Owner:TIANJIN SAIJIN ENERGY SAVING SCI & TECH CO LTD

A kind of iron oxide red production method

ActiveCN108975411BSolve pollution dischargeReduce consumptionFerric oxidesFerrous saltsPhysical chemistry

The invention discloses a production method of iron oxide red, which belongs to the technical field of chemical pigments. The method comprises adding metallic iron and water into a closed seed crystal reactor, heating up to a predetermined initial reaction temperature; adding dilute nitric acid into the seed crystal reactor, and feeding oxygen at the same time to react to prepare iron oxide red Seed slurry: adding the iron oxide red seed slurry with water, ferrous salt and metallic iron into a closed two-step oxidation reactor or adding the iron oxide red seed slurry with water, ferrous nitrate and alkali Add it into a closed two-step oxidation reactor; feed it with oxygen, and raise the temperature to the predetermined temperature of the second-step oxidation reaction to carry out the oxidation reaction to obtain iron oxide red. The invention solves the problem of nitrogen oxide pollution emission from the process source. Moreover, the consumption of ferrous nitrate per kilogram of iron oxide red produced by the production method is also less than that consumed by other processes, which reduces the production cost and is economical and practical.

Owner:河北恒丰化工科技有限公司

A solid heat storage electric boiler two-stage heat exchange oil field steam injection boiler heating system

ActiveCN106765004BSolve pollution dischargeSolve the problem of peak and valley electricity balance in the power gridFluid removalElectrode boilersThermal energyProcess systems

Owner:HEPU TECH DEV BEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com