Tin loaded porous carbon based solid acid catalyst as well as preparation method and application thereof

A technology of solid acid catalyst and porous carbon, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to improve conversion efficiency, avoid polymerization and hydrolysis, and improve effective The effect of diffusing away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of supported tin porous carbon-based solid acid catalyst: 1g furfural slag, 0.5g ZnCl 2 with 0.5g SnCl 4 Mix with 10g of ultrapure water, soak for a week, then dry in an oven at 60°C for 6h, then place in a tube furnace, heat up to 400°C for 2h under a nitrogen atmosphere, and obtain carbonized furfural slag; put the carbonized furfural slag in water, and use The stirring bar was stirred for 3 hours, the sand core funnel was filtered and washed, and dried to obtain the desired solid acid catalyst.

[0036] The acidity of the prepared catalyst was 1.43mmol / g, and the tin loading was 9.81wt%.

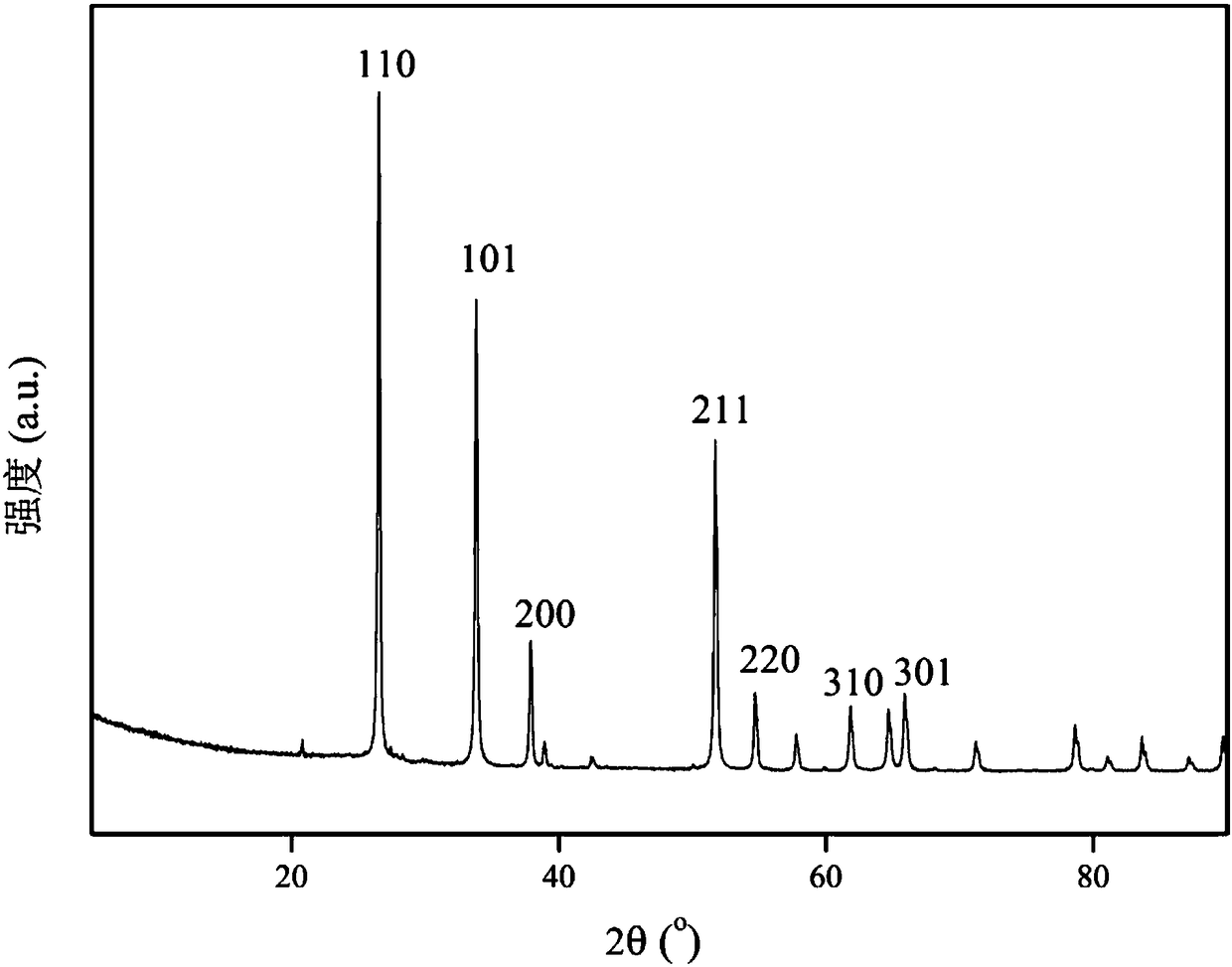

[0037] The XRD pattern of the prepared loaded tin porous carbon-based solid acid catalyst is as follows figure 1 shown by figure 1 It can be seen that tin atoms are supported on the catalyst.

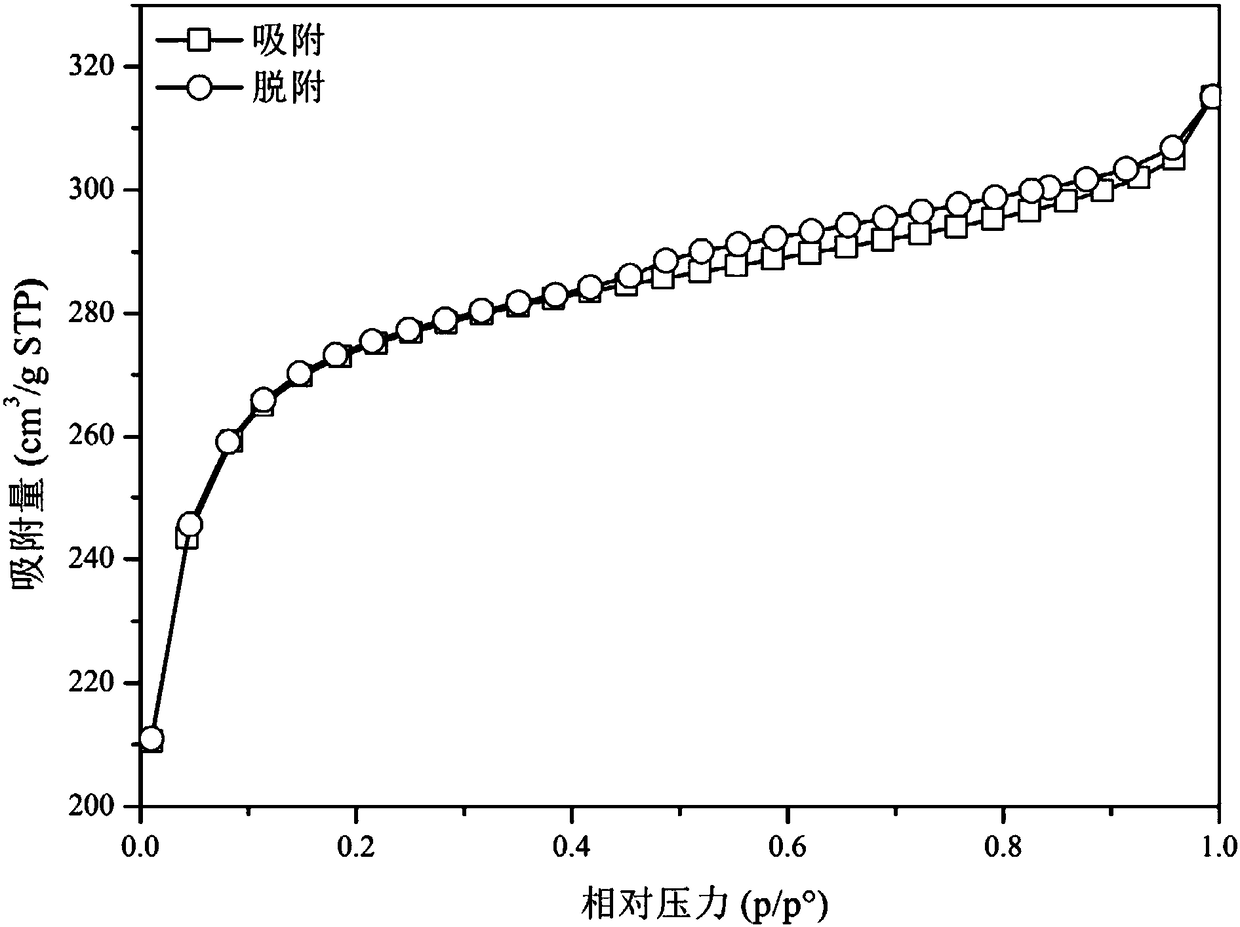

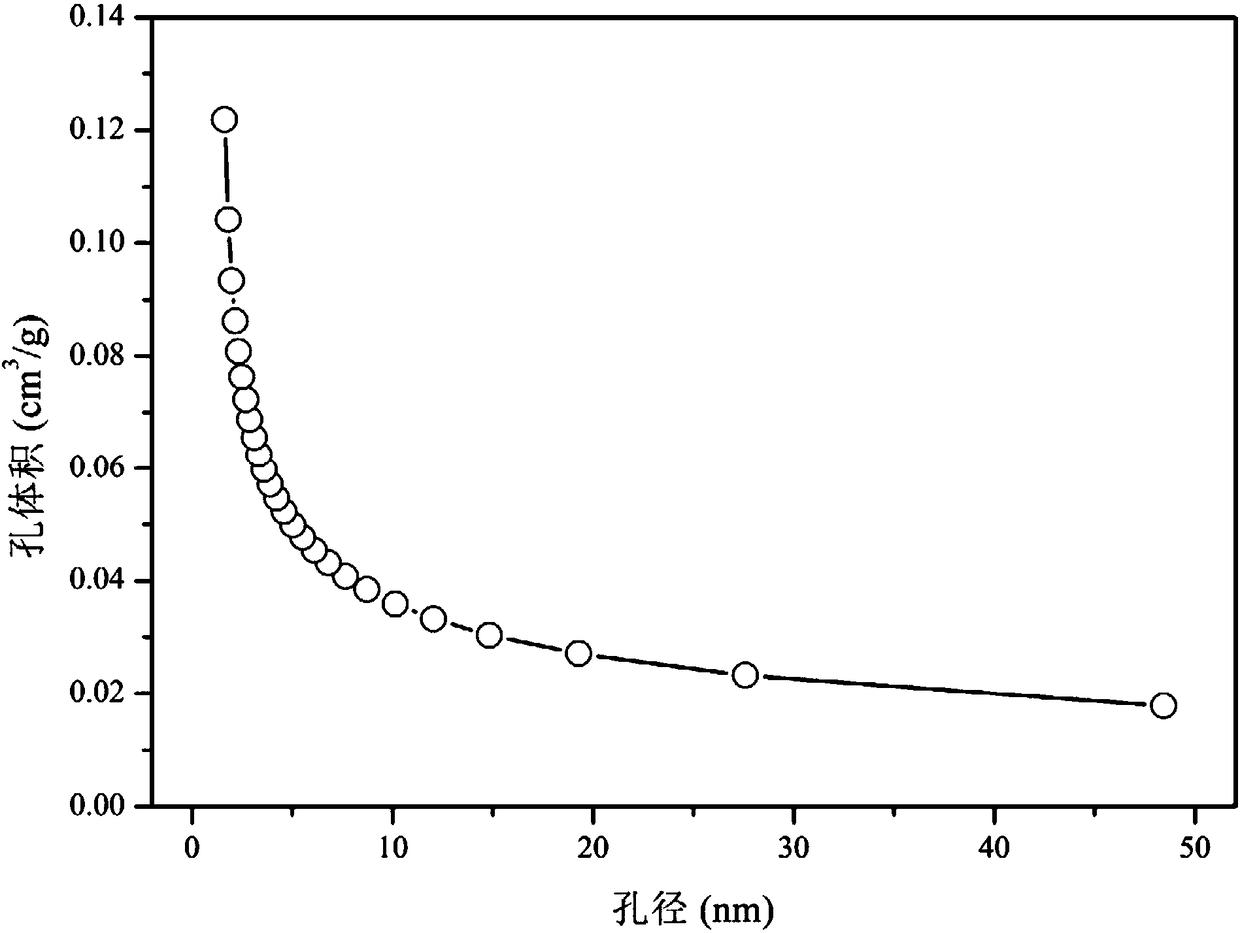

[0038] The N adsorption-desorption curve of the prepared loaded tin porous carbon-based solid acid catalyst is as follows figure 2 shown by figure 2 It can be seen th...

Embodiment 2

[0050] (1) Preparation of supported tin porous carbon-based solid acid catalyst: 1g bean dregs, 2g H 3 PO 4 with 2g SnCl 2 Mix with 30g of ultra-pure water, soak for two weeks, then dry in an oven at 70°C for 9 hours, then place in a tube furnace, heat up to 600°C under a nitrogen atmosphere and carbonize for 6 hours to obtain carbonized bean dregs; put carbonized bean dregs in water and stir for 6 hours , filter and wash with a sand core funnel, and dry to obtain a tin-loaded porous carbon-based solid acid catalyst.

[0051] The acidity of the prepared catalyst is 1.09mmol / g, and the specific surface area is 986.51m 2 / g, the tin loading is 8.56wt%; the catalyst has a porous structure including micropores and mesopores, and the pore volume is 0.23cm 3 / g, the average pore diameter of the pore structure is 4.69nm.

[0052] (2) Catalyst catalyzed xylan to prepare furfural: After mixing 0.3g xylan, 0.1g prepared tin-supported porous carbon-based solid acid catalyst, and 10mL...

Embodiment 3

[0058] (1) Preparation of supported tin porous carbon-based solid acid catalyst: 1g corn silk, 4g H 3 PO4 with 4g SnCl 4 Mix with 100mL ultrapure water, soak for three weeks, then dry in an oven at 80°C for 12h, then place in a tube furnace, heat up to 800°C for 10h under a nitrogen atmosphere to obtain carbonized corn silk; put the carbonized corn silk in water, Stir for 12 hours, filter and wash with a sand core funnel, and dry to obtain a tin-loaded porous carbon-based solid acid catalyst.

[0059] The acidity of the prepared catalyst is 1.09mmol / g, and the specific surface area is 1026.35m 2 / g, the tin loading is 10.26wt%; the catalyst has a porous structure including micropores and mesopores, and the pore volume is 0.33cm 3 / g, the average pore diameter of the pore structure is 4.82nm.

[0060] (2) Catalyst catalyzed corncobs to prepare furfural: mix 0.5g corncobs, 0.3g prepared tin-loaded porous carbon-based solid acid catalyst, and 10mL γ-valerolactone, put them in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com