A kind of cesium tungstate slurry for PVB safety glass and preparation method thereof

A technology of safety glass and cesium tungstate, which is applied in the direction of film/sheet without carrier, non-polymer adhesive additive, adhesive, etc., can solve the problem of large pollution discharge, etc., and achieve simple process steps, excellent transparent heat insulation performance , easy to promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example provides a cesium tungstate slurry for PVB safety glass, including the following components in mass percentage:

[0042] Cesium tungstate powder 20-40%,

[0043] Dispersant 5-15%,

[0044] Surplus is PVB plasticizer;

[0045] The PVB plasticizer comprises triethylene glycol diisocaprylate;

[0046] The particle diameter of the cesium tungstate powder is 10-30nm. The particle size of cesium tungstate powder is 10-30nm, which refers to the particle size of cesium tungstate powder in cesium tungstate slurry for PVB safety glass.

[0047] Among the above components, the amount of dispersant added is added with reference to cesium tungstate powder, and the amount of dispersant added is 5-15% relative to the mass of cesium tungstate powder, that is, 1-6% after conversion into absolute mass percentage. %.

[0048] Wherein, the dispersant includes at least one of polyethylene glycol, glycerin, polyvinyl alcohol, BYK-110, BYK-160, BYK-162, BYK-180.

Embodiment 2

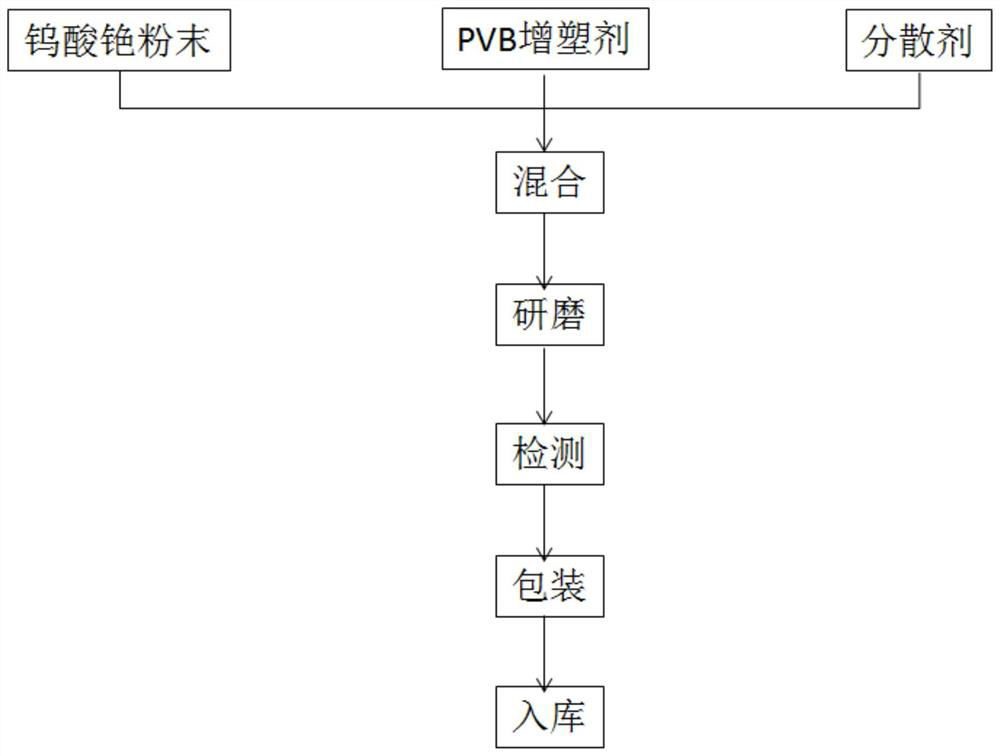

[0050] This example provides the preparation method of cesium tungstate slurry for PVB safety glass, the steps include:

[0051] S1: Weigh the cesium tungstate powder, dispersant and PVB plasticizer according to the proportion, add the dispersant into the PVB plasticizer under stirring condition, and obtain the medium system after mixing;

[0052] S2: Add the medium system of step S1 into the grinding equipment, add the cesium tungstate powder in batches after starting the machine, and obtain the cesium tungstate slurry for PVB safety glass after grinding.

[0053] Wherein, the stirring speed in step S1 is 100-200 rpm.

[0054] The grinding equipment described in step S2 is a sand mill. The grinding time is 18-22 hours. The grinding speed is 2800-3200rpm.

[0055] The above also includes pulverizing the cesium tungstate powder before step S2, and after pulverization, the particle size of the cesium tungstate powder is less than 20 μm. The complete process such as figure 1...

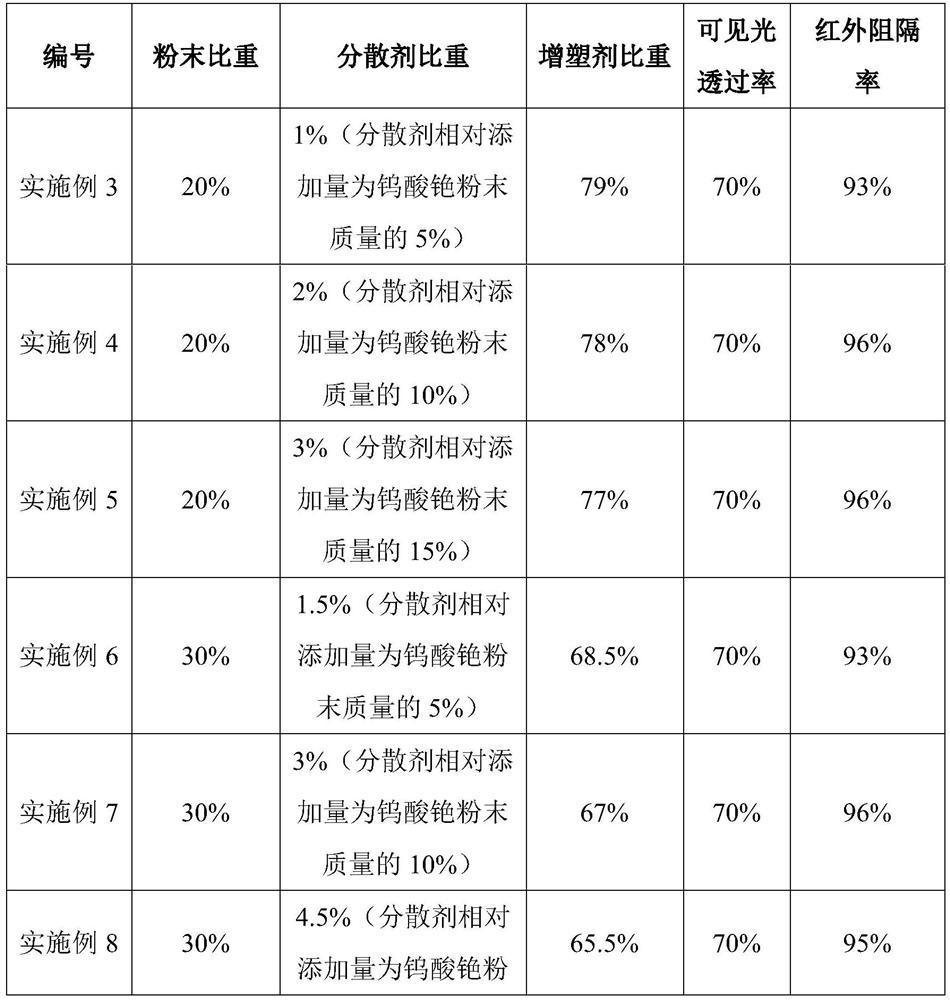

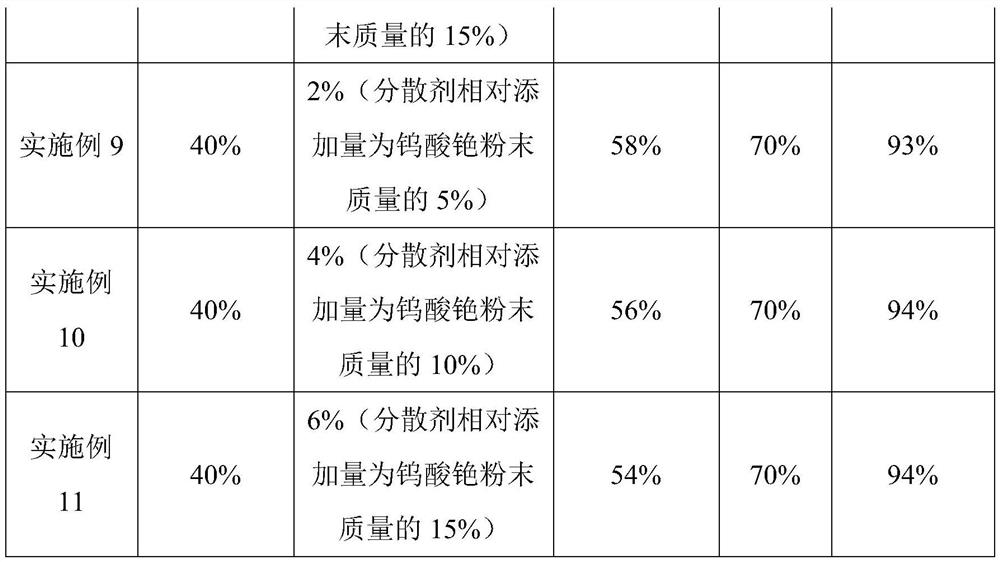

Embodiment 3

[0057] In this example, a cesium tungstate slurry for PVB safety glass was actually prepared, specifically:

[0058]Add 7.9kg of plasticizer to the circulating mixing tank, add 0.1kg of dispersant during stirring, and stir for 10 minutes until the mixture is uniform;

[0059] Weigh 2kg of cesium tungstate powder, crush it mechanically, and pass through a 300-mesh sieve;

[0060] Turn on the sand mill cycle, and adjust the machine speed to 3000r / min;

[0061] Gradually add cesium tungstate powder to the circulating stirring tank at a rate of 300g / 5min. After the addition is complete, start timing and grind for 20 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com