A super audio electromagnetic rod

An electromagnetic rod and super-audio technology, applied in the direction of electric/magnetic/electromagnetic heating, electric heating devices, electrical components, etc., can solve problems such as low service life, rising ambient temperature, heat conduction loss, etc., and achieve extended service life and fast heating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

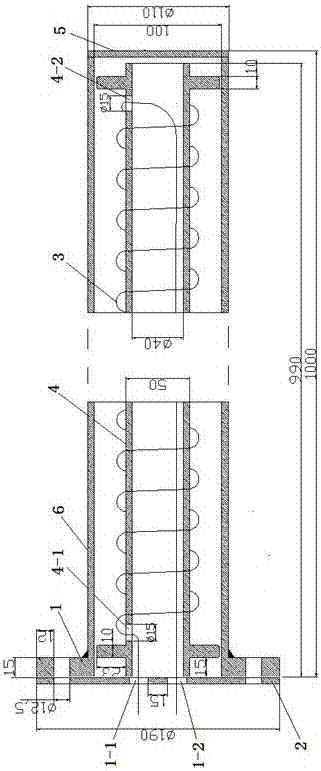

[0024] like figure 1 As shown, a super-audio frequency electromagnetic rod includes a flange 1, a flange 2, a coil 3, a ceramic tube 4, a bottom plate 5, and a stainless steel heating tube 6.

[0025] One end of the stainless steel heating tube 6 is welded with a bottom plate 5, and the opening of the other end is welded with a flange 2, and several coils 3 are wound on the outside of the ceramic tube 4 at intervals. The upper outlet hole 4-1 of the ceramic tube 4 enters the ceramic tube 4 and extends out of the flange 1 hole I1-1 connected to the flange 2, and the joint at the other end of the coil 3 passes through the lower outlet hole 4-1 of the ceramic tube 4. 2 enters the ceramic tube 4 and extends out of the hole II1-2 of the flange 1 connected with the flange 2.

[0026] The stainless steel heating pipe 6 adopts 0Cr13 410s stainless steel pipe with an outer diameter of 110mm and a length of 1000mm.

[0027] The outer diameter of the ceramic tube 4 is 50 mm, and the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com